Working in an environment with ignitable vapors is one of the most dangerous places to operate equipment. In a C1D2 workplace, one small spark from a light or heating element can lead to catastrophe. These locations need to stay in full operation all winter long. As a result, they expose their sensitive equipment and materials to cold harsh temperatures. So how do these locations keep their equipment warm, when the explosion risk is so high? Let’s take a closer look.

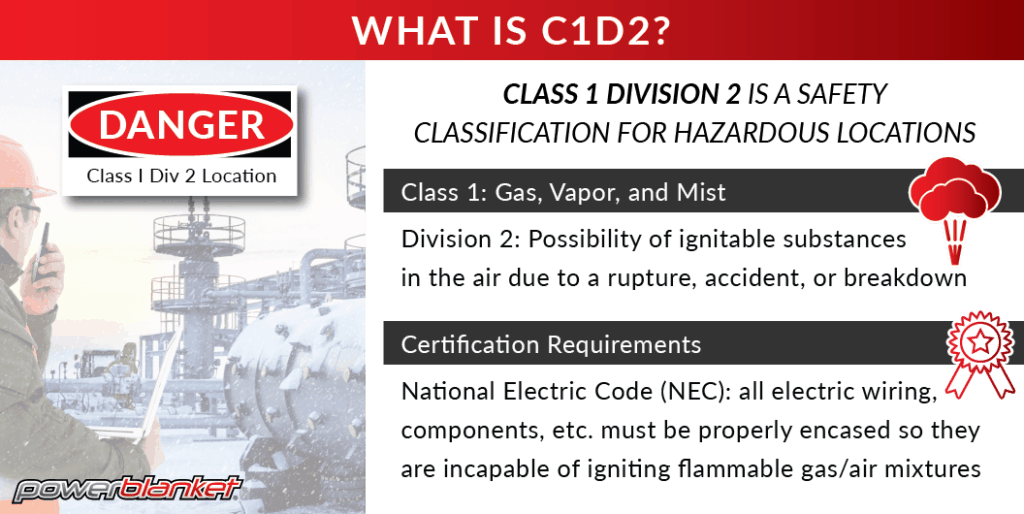

What is C1D2?

Class 1, Division 2 is a safety classification that includes locations where volatile flammable liquids, gases, or vapors are used but are typically confined in closed systems or containers. Within all Class 1 hazardous locations, there is a possibility that there are ignitable substances in the area’s air. In addition, Division 2 locations only have ignitable substances in the air if there is some sort of rupture, accident, or breakdown.

C1D2 Location Restrictions

The National Electric Code sets forth strict requirements for any electrical equipment being used in a C1D2 area. In order for an electric device to achieve a C1D2 certification all components, circuitry, cables, and wires must be in non-incendive enclosures. Thus the electrical components are encased so they are incapable of igniting a flammable gas/air mixture. This includes internal electrical components, wiring that is leaving or entering a piece of equipment, and the power supply.

C1D2 Heating Needs

Industrial process heating are critical in keeping equipment warm and operable. During harsh winter conditions, cold temperatures adversely affect industrial fluids, gases, equipment, and more. As a result, keeping an industrial center running smoothly all winter long takes planning and preparation.

Powerblanket C1D2 Heating Solutions

So, how do you know which heating products are safe to use in a C1D2 environment? The proof is in the certification. Powerblanket has developed the most advanced hazardous location freeze protection products on the market, complete with special wiring and safety equipment to ensure the highest standards of safety. We thoroughly test and certify our hazardous location heating blankets to the most stringent safety standards. In addition, heavy duty vinyl insulation ensures wind and water resistance.

Our world class engineers are on stand by to create a tailor-made heating solution for your needs. We are proud to have the fastest turn around time in the market for custom orders. We customize our heating blankets to fit your application perfectly.

If you can build it, haul it, or store it, Powerblankent can heat it. No matter what size or material, or what type of vapor is in the air, Powerblanket’s process heating solutions ensure your safety and efficiency needs are met. Contact us at 855.524.2695 or [email protected]

Keep your equipment running smoothly and prevent damage with Powerblanket's advanced hazardous location heating systems.