Valin Corporation is a leading technical solutions provider for the technology, energy, life sciences, natural resources, and transportation industries. They came to Powerblanket with a process heating engineering dilemma, and our world-class engineers came up with a solution.

What was the heating dilemma?

Valin’s problem centered around their work within the oil and gas industry. Pumps were getting too cold and shutting down, slowing production and wasting time and money. They had tried to use electric heat tape to solve the problem. Unfortunately, electric heat tape products do not allow for temperature regulation. Consequentially, the tape got too hot and melted the rubber portion on the pump.

They were in great need of a heating solution that contained self-regulating thermostats, and that was certified to comply with C1D2 safety requirements. In addition, this process heating solution also needed to be tailor-made to cover the pumps’ varying shapes and sizes.

What is C1D2?

Class 1, Division 2 is an OSHA classification that includes locations where volatile flammable liquids, gases, or vapors are used but are typically confined in closed systems or containers. C1D2 locations are only considered hazardous if there was an accident or breakdown. Within all Class 1 locations there is a possibility that there are ignitable substances in the area’s air.

What Can Be Used In a C1D2 Location?

The National Electric Code sets forth strict requirements for any electrical equipment being used in a C1D2 area. In order for an electric device to achieve a C1D2 certification all components, circuitry, cables, and wires must be in non-incendive enclosures. This means that under normal conditions, the electrical components are encased so they are incapable of igniting a flammable gas/air mixture. This includes internal electrical components, wiring that is leaving or entering a piece of equipment, and the power supply.

Powerblanket Heating Solutions

So the Valin field site sales manager provided Powerblanket engineers with the necessary information and measurements. They then set to work to create a solution with a good fit for each pump. Next, Valin tested the initial heating blankets for form and fit and Powerblanket made minor modifications for the final order. We provided a pricing level that fit within Valin’s budget. As a result, each pump now has a custom made, C1D2 certified, heating blanket, with a self-regulating thermostat.

Time, Money, and Stress Averted

Valin found wintertime peace of mind with Powerblanket. They no longer have to worry about pumps and stators freezing and shutting down operations. The blankets heat evenly without getting too hot or damaging rubber rings on pumps. Because of this process heating engineering solution, Valin can install their blankets and rest easy about the efficiency and safety of their operations.

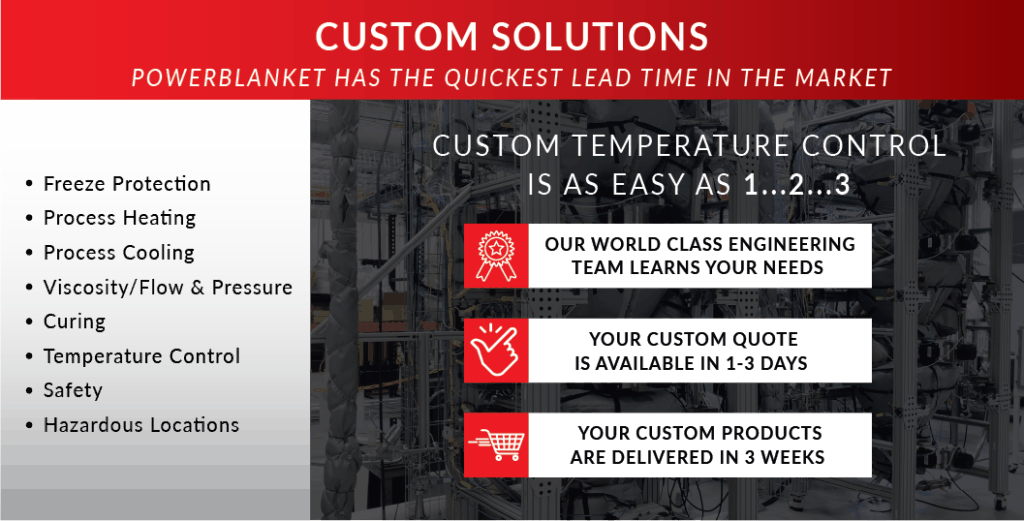

Powerblanket will keep you running all winter long and save you time, money, and hassle. We have the fastest lead times on the market for custom orders. We provide custom quotes with 1-3 days and ship custom orders within 1-3 weeks. Learn more about our custom pipe heater blankets that are tailor made to fit your equipment. Contact us at 855.977.9657 or [email protected].

When you need a custom temperature control solution, Powerblanket is the company to call. With over 30 years of experience, we can solve any heating dilemma you have.