The candle industry is on fire, literally and economically. Consumers are not only flocking to sites, stores, and candle parties to satisfy their candle needs. They are also capitalizing on the flood of DIY information available in an increasingly digital world. Candle making is part science and part art form. Candle manufacturers and DIY enthusiasts need to be well informed on the chemistry of wax melting and combustion, as well as the art of balancing fragrances, colors, and textures to make a functional and attractive product. Let’s take a more in depth look at 1 of the most important pieces of candle making equipment, wax melters.

Types of Candle Wax

Paraffin Wax

Paraffin is a colorless wax that contains no additives. It is inexpensive, very easy to use, and a common medium for pillars, tapers, votives, tea lights, and container candles. Paraffin easily accepts dyes and fragrances.

Beeswax

One of the most popular waxes is 100% natural beeswax. It is very versatile for all candle types, and also comes in attractive honeycomb sheets for rolled candles. It is more difficult to add colors and scents to beeswax.

Soy Wax

Made from hydrogenated soybean oil, this candle medium is best suited for container candles. It has a more unique flat finish to it than paraffin, and often requires more dyes to achieve the desired colors.

Palm Wax

Palm wax is made from hydrogenated palm oils. In a solid state it has a crystalline or feathered texture to it. It is a wonderful medium to use for pillars and votives.

Gel

This candle medium is actually not a wax at all. Gel candles are made from mineral oil and a polymer resin and should only be placed within a container. It is completely clear when in its solid state, and easily shows off decorative accents dispersed throughout the candle.

Wax Melters

There are many things to look for in a wax melter. A safe heating temperature range is the most important melter feature.

Melting and Smoke Points

Each type of candle wax has a range of melting points depending upon the wax manufacturer. Be sure to carefully read your product info so you are aware of what temperature your wax transforms from a solid to a liquid.

Candle waxes also have smoke or flash points at which they become damaged from overheating. When a candle wax overheats it smokes, sizzles, discolors, and develops an unpleasant aroma. If it continues to overheat, it can ultimately auto-ignite. Your preferred wax distributor will also include a range of smoke and flash point temperatures. Dyes and fragrances also have individual smoke and flash points, so be sure to read all ingredient labels carefully before heating.

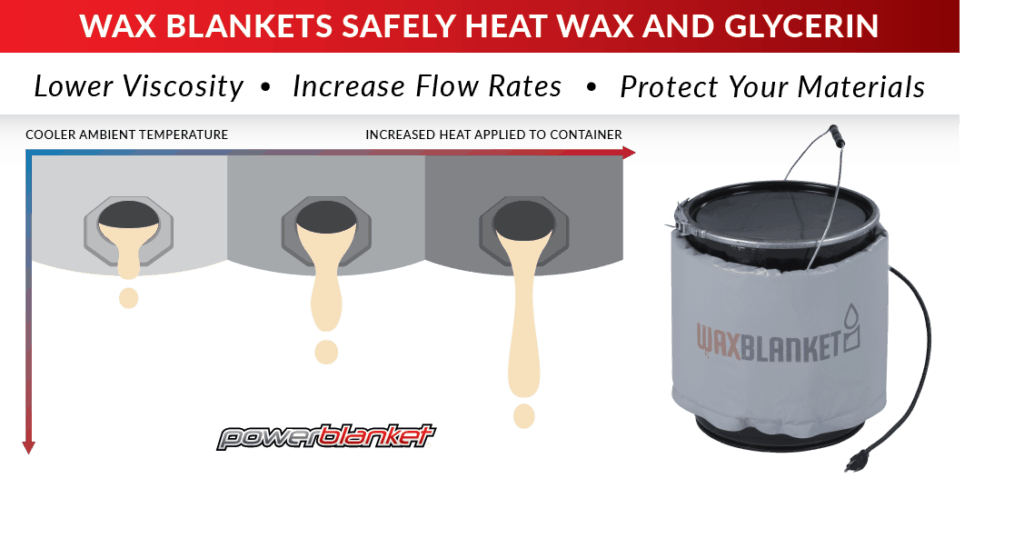

Viscosity Problems

When it comes to storing large amounts of wax in buckets, barrels, or drums, viscosity maintenance is critical. Highly viscous liquids are thick and difficult to work with. It is important that waxes remain at lower viscosity levels in order to keep them liquid and flowing. Proper wax viscosity allows you to mix, pour, decorate, and adjust wicks easily and efficiently.

The best wax melters heat evenly over the entire container surface to reduce uneven melting and make sure you have uniform wax viscosity.

Powerblanket Wax Melting Solutions

There are a lot of wax melters on the market. They range from inefficient melting pots that only heat from the bottom, time consuming double boilers, to bulky and expensive immersion melters. Powerblanket offers a solution so you can enjoy the candle making process and free yourself from babysitting wax temperatures.

Wax Blankets

Powerblanket wax melting blankets are equipped with thermostatic controls that allow you to set the proper temperature and walk away. There’s no need to babysit the heating process. Our internal preset thermostats solve your viscosity issues without reaching smoke or flash points.

Powerblanket’s full wrap-around design ensures even heating across the entire container surface, eliminating hot and cold spots. Our wax melting blankets are also perfect for soap making. Let Powerblanket save you time, and money by safely and evenly heat glycerin to prepare for pouring.

Contact us to find the perfect wax melting solutions for all your candle and soap making needs at 855.408.3872 or [email protected]

The Wax Blanket is designed to safely and efficiently melt your wax or glycerin into a usable liquid form with minimal attention on your part.