Your Solution is Right in Front of You

The answer is Powerblanket.

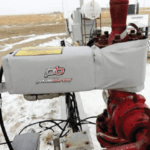

The number one name in oil and gas line freeze protection, Powerblanket is the leading provider of standard and custom-designed industrial heating blankets. Engineered to function in the harshest of conditions, Powerblanket heating blankets are used globally to combat low temperatures in the oil and gas industries. Our equipment serves to maintain viscosity in oil flow, prevent gas from condensing, and stop valves from freezing up. Powerblanket’s heating blankets have time and again saved the day and the fiscal year for oil and gas companies, with impacts reaching all the way to the consumer.

Powerblanket Makes All the Difference

Gas companies like McADA know this firsthand. They used Powerblanket to provide heat to sensitive equipment, allowing them to serve more customers and save money. In fact, the money saved after just two weeks covered the cost of the Powerblanket equipment.

Watch the oil and gas overview video below to find out about some of our products and how they have helped companies like McADA.

Transcript: In the oil and gas industry, winter means frozen pipes and faulty equipment. Ever considered how much cold weather costs your business?

McADA did. As a fracking fluids heating company, the company used to heat its truck mounted propane tanks with tarps and space heaters. It was a slow process and limited the number of customers they could serve. They turned to Powerblanket for a better solution.

With Powerblanket heaters, McADA now services customers faster, even in colder conditions, and reduced its service costs while growing its business. The custom heaters paid for themselves in just two weeks.

Or consider a large energy service provider that faced losing thousands of dollars in profits a day if their wellhead pressure transmitters froze. Powerblanket stepped in and designed custom heaters that eliminated the threat of frozen pressure transmitters–forever.

Powerblanket® heaters can be tailored or custom designed to fit any job, and any weather condition.Face cold weather with confidence. Let Powerblanket weatherproof your business for good.

A Heating Blanket for Every Occasion

Powerblanket manufactures heating blankets that are built precisely for your needs. Most often, those needs can be fulfilled in our standard line of high quality products. Other times, you need a custom solution to your temperature woes. Powerblanket does both, allowing you to obtain the best result for your business.

Powerblanket: A One-stop Heat Shop

Powerblanket is the answer for every heating need:

- Oil Flow: Cold air temperatures will increase the viscosity of oil until it runs like sludge. Powerblanket heating wraps can hold fluids at optimum flowing temperatures, freeing up your oil to move through pipelines.

- Storage: Natural gas and propane both naturally condense in cold weather, lessening pressure in the tanks they’re stored in. This reduces the gas’ ability to vaporize and exit the storage tank, giving you less gas to work with. Heating blankets fix this problem by preventing the storage tanks from getting too cold, maintaining pressure and increasing the amount of gas that vaporizes.

- Valve Freezes: Valves are virtually guaranteed to freeze up during winter months, especially in environments where moisture in the air is a factor. Not being able to open and close a valve is more than lost time; it’s also a serious safety issue. Keeping the valves warm will prevent this from happening. Powerblanket’s heating blankets can be wrapped around valves, bringing heat in to stop ice from building up. The blankets can be fitted specifically to each valve, allowing easy access to the valve without having to remove the blanket for use.

No matter what your heating issue is, Powerblanket has it covered. From bulk purchases to custom orders, our oil and gas industry experts are ready to get you the equipment you need, making it seem like the cold was never there. For more information, call 844.903.1837 or visit [email protected].

Powerblanket's custom tank heaters provide freeze protection, making your business more sustainable and efficient.