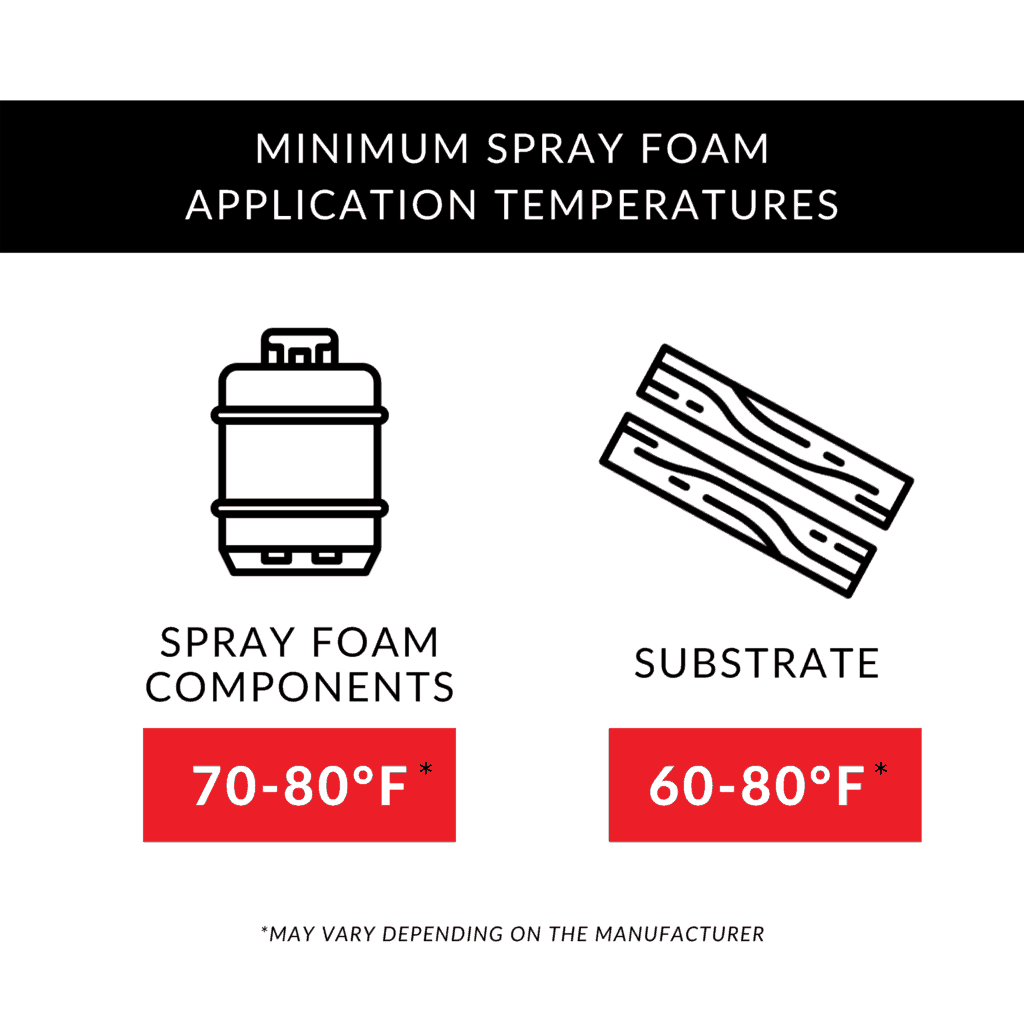

Spray foam insulation rocks. As building insulation, it provides some dang impressive thermal resistance and even sound barriers. Whether in storage or in use, spray foam must be kept between 70 and 80 degrees. It also generally adheres best when substrate temperatures are no lower than 60 F. While it *is* possible to install spray foam in cold temperatures, there are a few things to keep in mind before jumping into a cold-weather spray foam application.

Spray foam insulation rocks. As building insulation, it provides some dang impressive thermal resistance and even sound barriers. Whether in storage or in use, spray foam must be kept between 70 and 80 degrees. It also generally adheres best when substrate temperatures are no lower than 60 F. While it *is* possible to install spray foam in cold temperatures, there are a few things to keep in mind before jumping into a cold-weather spray foam application.

Let’s Get Chemical: What Exactly is Spray Foam?

Spray foam is a thermoset polymer. In layman’s terms, this means it starts out as a liquid then goes through a chemical reaction and becomes a set, heat-resistant solid.

Before use, spray foam is actually stored as two separate chemical components. As they’re sprayed, the two components mix and rapidly heat as they cure into a solid form.

Why Spray Foam and Cold Aren’t Friends

There are a couple of reasons why colder temps keep spray foam from doing it’s thing.

Low Expansion

First, in cold environments, spray foam will not expand as much as it does in warmer conditions. This means spray foam projects take much longer and require more product.

Condensation

Second, when exposed to cold ambient temperatures and cold substrate, exothermic spray foam will

create condensation that prevents adequate adhesion.

“Think about a pop can in the summer,” says Amanda Ringler from RetroFoam, a Foam Insulation company in Michigan. “The cold can will start to form condensation because the hot air is coming into contact with it.” She then describes how the same thing happens when hot spray foam comes into contact with cold substrate. “Realize, depending on the manufacturer, the closed cell is between 130 to 150 degrees.”

When condensation isn’t addressed, the insulation won’t adhere properly to the substrate.

Minimum Temperature for Spray Foam Insulation

For spray foam to adhere and expand properly in cold weather, two important elements require consideration: First, the actual spray foam components and, second, the substrate, or surface on which the insulation will be sprayed.

Minimum Temperature for Spray Foam Components

Generally, spray foam likes being kept at temperatures between 70 and 80 F. These temperatures must be maintained during spray foam use as well as storage. Temperatures may vary slightly depending on the type of foam, so take time to read the specifications provided by the manufacturer.

Minimum Temperature for Spray Foam Substrate

Substrate minimum temperature requirements are a bit more variable. Most spray foam manufacturers specify a substrate temperature somewhere between 60 and 80F . However, some are designed to be applied in colder conditions.

How to Keep Things Toasty

While spray foam temperature requirements are generally on the warmer side, experienced contractors know how to successfully install spray foam when temperatures are less than ideal. Because spray foam components and substrate must be separately heated, cold-weather spray foam insulation often requires two heating solutions. Let’s take a look at some options for heating both the spray foam components and the substrate.

Heating Spray Foam Insulation Components

Spray foam canisters are usually kept in a heated trailer; the spray foam is pumped from the canisters to the application site via hoses. Here are a few common approaches to keeping canisters and hoses at ideal temps:

- Use a wall thermometer to monitor the air temperature of the trailer

- Use a laser thermometer to keep an eye on canister temperatures

- Store canisters on top of 2x4s to allow warm air to circulate underneath.

- Wrap canisters in heated blankets

- Install a small flap door (think doggie door) in the trailer to serve as an exit point for the hose. This will allow much less cold air to enter versus opening a large door.

- Replace your hose at least every two years. Insulation properties stop performing as well over time.

- Ask your supplier sales rep about options for insulated hoses.

- Keep the hose off of snow, ice, and cold surfaces.

- Park the trailer as close to the building entrance as possible to keep the hose inside at warm temperatures.

- Keep the building heated for at least 24 hours after spray foam application to ensure proper curing.

Heating Spray Foam Substrate

As mentioned earlier, when the substrate surface is too cold, significant condensation will form when spray foam is applied and the insulation won’t properly adhere.

Most often, contractors will use a torpedo heater to raise building and substrate temperatures prior to spray foam insulation. It’s important to note that these heaters produce moisture. A simple moisture meter can be used to ensure substrate surfaces do not exceed a moisture level of 18%.

Also worth mentioning is that the substrate temperature will not always be the same as the ambient temperature. Just because the ambient temperature of the building has reached 60 F does not mean that the substrate temperature is warm enough. Use a laser thermometer to pinpoint substrate temps.

Before applying spray foam, the heater must be turned off. When spray foam fumes are drawn through the heater, it can form toxic fumes.

Heat it Up with Powerblanket

At Powerblanket, we’re all about making those unavoidable wintertime jobs as easy as possible without compromising quality. Spray foam heaters cover the entire spray foam cylinder and prevent heat from leaking out, allowing you to keep running your business through the cold winter months. Avoiding product waste caused by temperature issues can lead to a much higher yield and better business.

Frequently Asked Questions

How cold is too cold for spray foam?

Spray foam insulation can technically be applied at temperatures as low as 5°F, but for optimal adhesion and expansion, the room temperature should be at least 40°F, with substrate temperatures ideally no lower than 60°F.

At what temperature will spray foam insulation ignite?

Cured spray foam is combustible and can ignite if exposed to temperatures above 240°F, so it should be kept away from high heat sources like heaters and fireplaces.

What temperature can you apply spray foam insulation?

Spray foam insulation should be applied at temperatures between 70°F and 80°F to ensure proper expansion and adhesion, although some formulations may allow for application in colder conditions with additional precautions.

What temperature should spray foam insulation be in an attic?

When insulating an attic with spray foam, maintaining temperatures between 70°F and 80°F during application helps ensure effective insulation and can significantly reduce attic temperatures during peak summer.

Keep your business running smoothly through the cold winter months with Powerblanket spray foam heaters.