Transmitters can be used for dozens of applications within industrial plants. They are designed to send a dependable signal no matter what the application.

When transmitters are used to send a data signal for liquids, pressure or even pulse lines- they most often use a manifold block with sets of needle valves that allow certain lines to flow or be blocked off. These manifolds feed the media up to the transmitter so that it can send it’s required signal.

A huge challenge in the field though is keeping these manifolds from freezing. If they get too cold, the product within them cannot get to the transmitter…and things start to shut down when the enterprise DCS/PLC or central control system cannot receive their required signals.

There are only a couple of solutions available for this critical application. Heat trace cant work, you can look at any of the instructions from any heat trace manufacturer- not one of them publish a set of directions for wrapping heat trace around this type of manifold. Heat trace installation instructions for all major manufacturers like Thermon, nVent (Raychem), Nelson, Chromalox all show how to install heat trace on pipes, pumps, valves… but nothing on transmitters.

Because it wont work. Smart.

Heated boxes are the most commonly specified solution to keep manifolds working. Heated boxes consist of a poly box with a hinged door (top or side). A heater is installed inside the box. That heater heats the air in the box, and transmitters are warmed by the air.

Heating the air to heat the instrument isn’t the most effective method, but it works, until it doesn’t. Heaters used to heat air and then heat a product have to work much harder than a heater that is custom fit right to the item being heated. It’s convective heat vs. conductive heat. Air is a very poor heat transfer medium. Just go to any old timer at a power plant or refinery and ask if horseshoe heaters last very long. Wait for a very animated emotional response.

When you look at the transmitter assembly, the only thing that really freezes is the manifold. The transmitter heads (normally called blue heads on site) are rated to really low ambient temperatures like -50F. They dont freeze. It’s the manifold that freezes up.

So what’s the best way to heat the manifold…by getting a heater right on it, while still allowing access to the needle valves, view displays and calibration points.

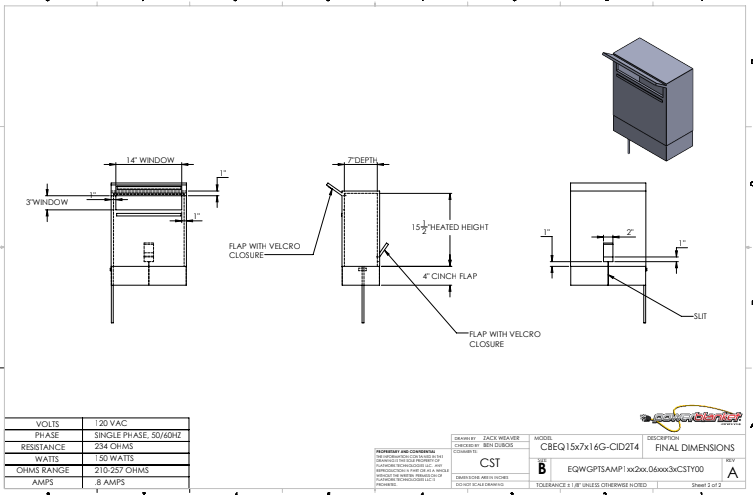

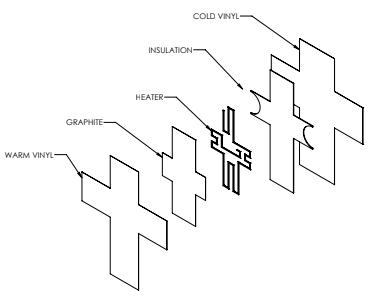

Powerblanket Transmitter heaters can be sized to fit directly over your head and manifold. Powerblanket units have heaters designed into the jacket walls, putting the heat right where you need it.

(real pic of problem- our designed solution below)

Units can have access flaps or holes to accommodate conduit or process tubing. Straps or Velcro openings can be included for easy access, and then a really nice tight fit once you close it back up.

Powerblanket units can run off of 120, 208 or 240 Volts, and can be certified to class 1 division 2 groups A, B, C or D , Class 2 Division 2 Groups E, F, or G, Class 3 Division 1 and T with a T rating of T3 through T6, as well as Class 1, Zone 2, IIC, and Class 2 Zone 22, IIIC, with a T3 to T6 Temperature rating. (Can/CSA-C22.2 No 130, UL 499, UL 121201)

Or we can make a unit that is not certified to these standards.

Give us a call today and let us show you how to really protect your instrument manifolds.

Frequently Asked Questions

What is freeze protection HVAC?

Freeze protection in HVAC systems involves maintaining a minimum indoor temperature to prevent freezing, similar to how heated enclosures or blankets are used to keep transmitter manifolds operational in cold conditions.

What is the purpose of a manifold in a pressure transmitter?

A manifold in a pressure transmitter serves to control the flow of media to the transmitter, allowing for isolation during maintenance and calibration, and preventing over-range conditions.

Powerblanket's equipment boxes keep your valves and manifolds from freezing in even the harshest outdoor environments.