Description

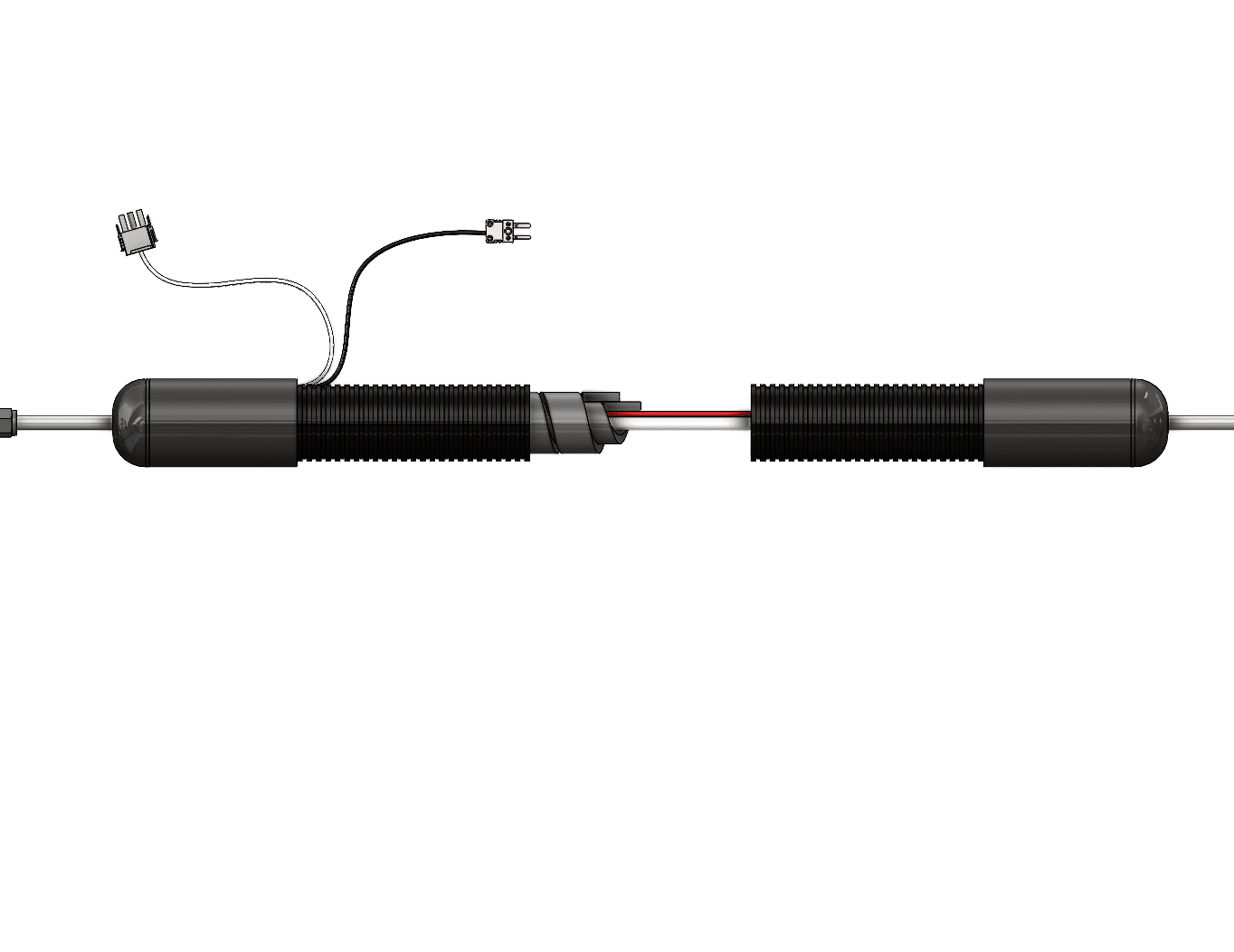

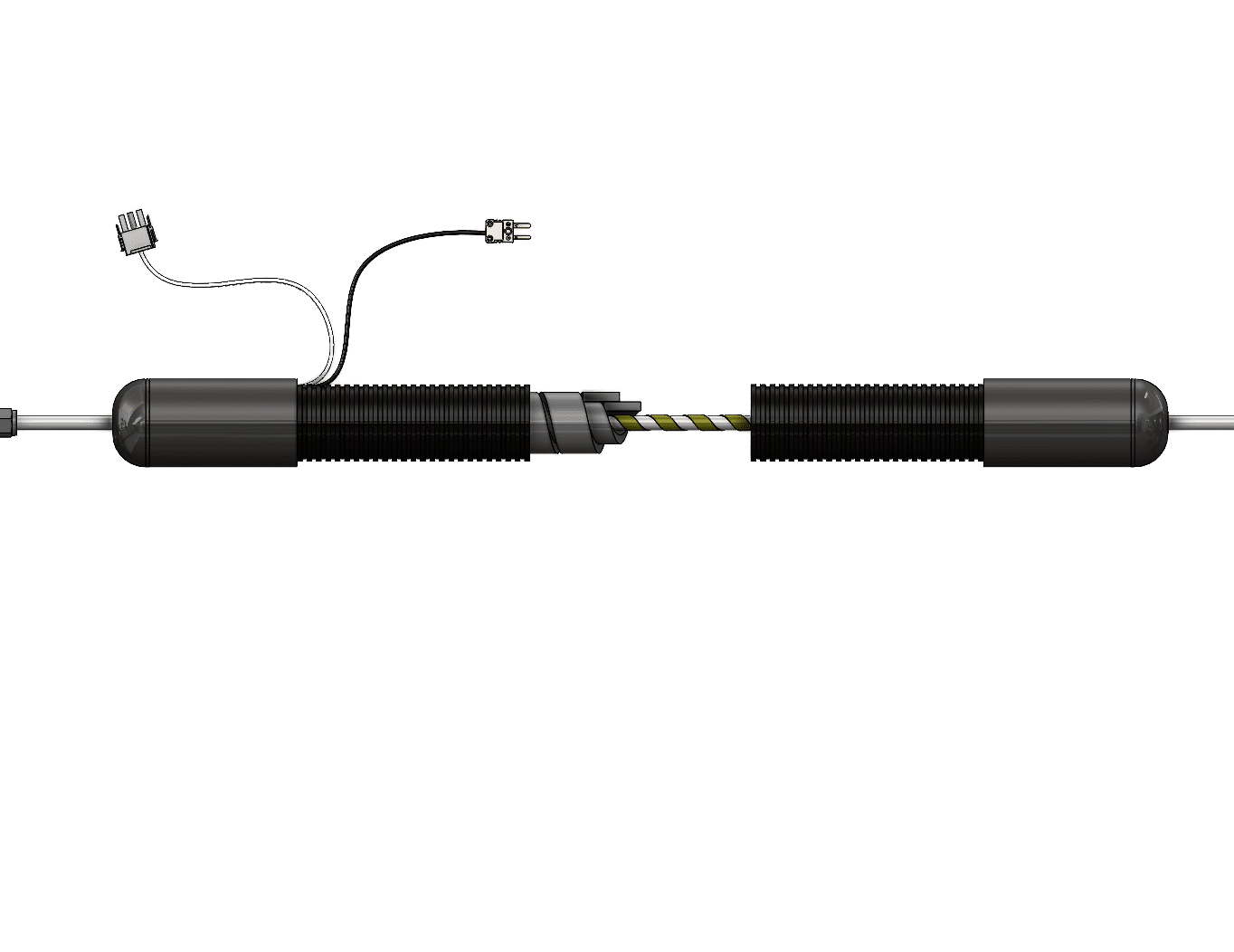

The Powerblanket/Thermon HSL1000 Heated Sample Line is a high-flex, tape-heater assembly engineered to maintain gas or liquid temperature from the collection point to the analyzer or process tool. Built around a polyimide/silicone-insulated alloy tape heater, HSL1000 delivers tight thermal coupling in a compact profile, ideal for tight routing and portable test setups. It’s a smart fit for CEMS/RATA, engine and chassis dyno testing, and lab or production environments where sample integrity and repeatability matter. Typical heated lengths range from 0.5–30 m (1.5–100 ft) with a minimum bend radius of 100 mm (4 in.), and maintenance temperatures up to 200 °C (400 °F) with closed-loop control. Choose standard Type K thermocouple feedback or upgrade to RTD/Thermistor to pair with your controller.

Available configurations include:

- Sample tube materials: PFA (standard), stainless steel, and others

- Outer jackets: Corrugated (washdown-ready) or braided sleeving (low profile)

- Insulation: Felt or closed-cell silicone foam (up to 1/2″)

- Terminations & connectors: Swaged or compression fittings; optional quick-connects; power/sensor plug options

- Controllers: GHT2002J, ExoTouch, or PID systems

Product Highlights

- Up to 200 °C (400 °F) maintain with precise closed-loop control

- 5–25 W/ft custom power density for application-matched performance

- High flexibility: ≤100 mm bend radius; compact OD options for tight spaces

- Heated length: 0.5–30 m (1.5–100 ft) typical; optimized for short runs under 50 ft

- Voltage options: 120/208/240/277 VAC for easy integration

Across the line, HSL1000 assemblies are built with industrial-grade materials and offer optional hazard-tolerant jackets and controller integration for consistent results and faster startup. Certifications/approvals are listed in the product documentation and controller manuals where applicable.

Reviews

There are no reviews yet.