Description

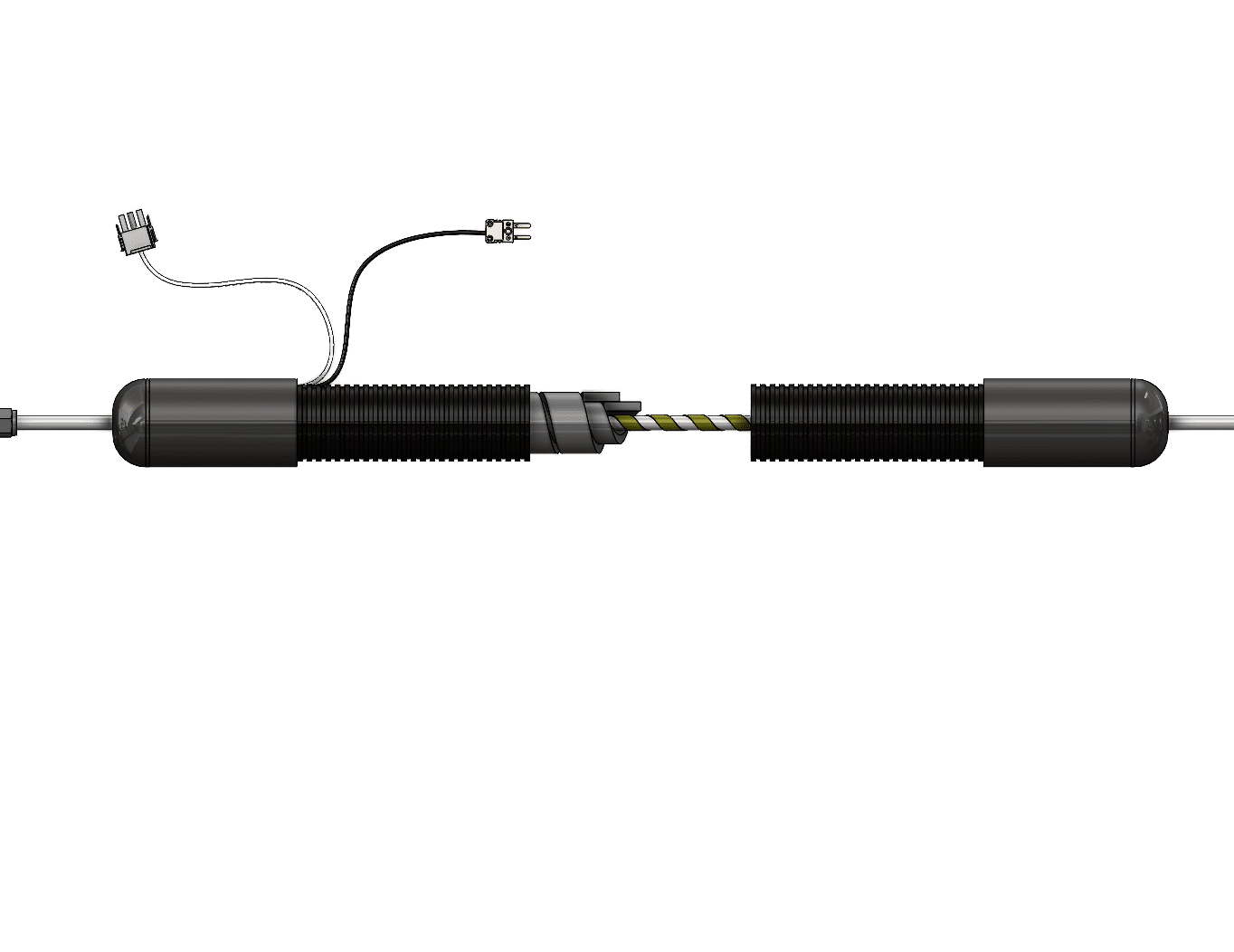

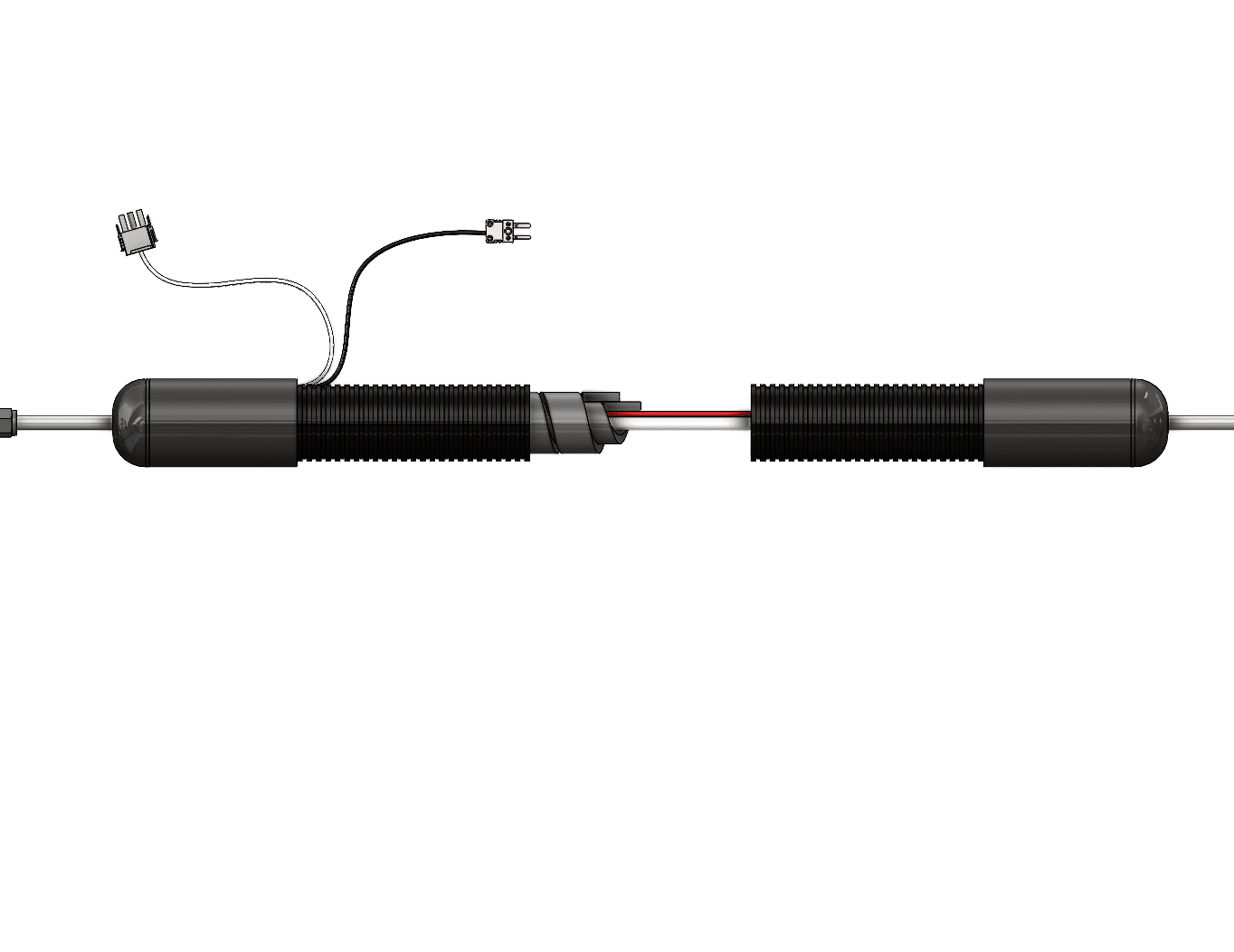

The Powerblanket/Thermon HSL2000 Heated Sample Line leverages Thermon self-regulating or power-limiting heat cable to deliver reliable temperature maintenance and freeze protection—even under changing ambient conditions. HSL2000 is purpose-built for ordinary and hazardous areas (Zones 1, 2, 21, 22), making it a strong choice for fixed CEMS, field RATA work, midstream gas sampling, and semiconductor/process umbilicals. Typical heated lengths are 0.5–30 m (1.5–100 ft) with a 100 mm (4 in.) minimum bend radius. With proper control, HSL2000 supports maintenance temperatures up to 200 °C (400 °F) and standard Type K feedback, with RTD/Thermistor options to match your control hardware.

Available configurations include:

- Heat cable families: self-regulating and power-limiting options at common watt/ft classes

- Outer jackets & insulation: Corrugated or braided shells; closed-cell foam or felt insulation (to 1/2″)

- Terminations & plugs: Multiple power/sensor lead lengths; Molex/Amphenol/Leviton plug styles

- Tube materials & fittings: PFA (standard) with swaged or compression fittings; optional quick-connects; raw ends

Product Highlights

- Hazardous-area ready: designed for use in Zone 1/2/21/22 applications (see heater cable approvals)

- Up to 200 °C (400 °F) maintain with compatible controllers

- 5–20 W/ft custom power density classes to fit ambient and setpoint needs

- High flexibility: ≤100 mm bend radius; rugged jacket options for field work

- Heated length: 0.5–30 m (1.5–100 ft) typical; optimized for short runs under 50 ft

Across the line, HSL2000 pairs self-regulating safety with Thermon-grade components to reduce risk of hot spots and simplify installation, supported by controller options and industrial connectors for a clean, reliable setup.

Reviews

There are no reviews yet.