In early 2021, Texas was hit hard by an energy crisis that rattled its core infrastructure and left many of its residents without heat or running water for days. As extreme weather made its way through the state, production of natural gas came to a standstill. Blackouts shortly followed. This was due to a lack of preparation by power plants in the state to protect their systems and processes. As homes and businesses froze, the demand for natural gas only increased, exposing the need for a greater understanding of proper preparation for power plants in freezing conditions.

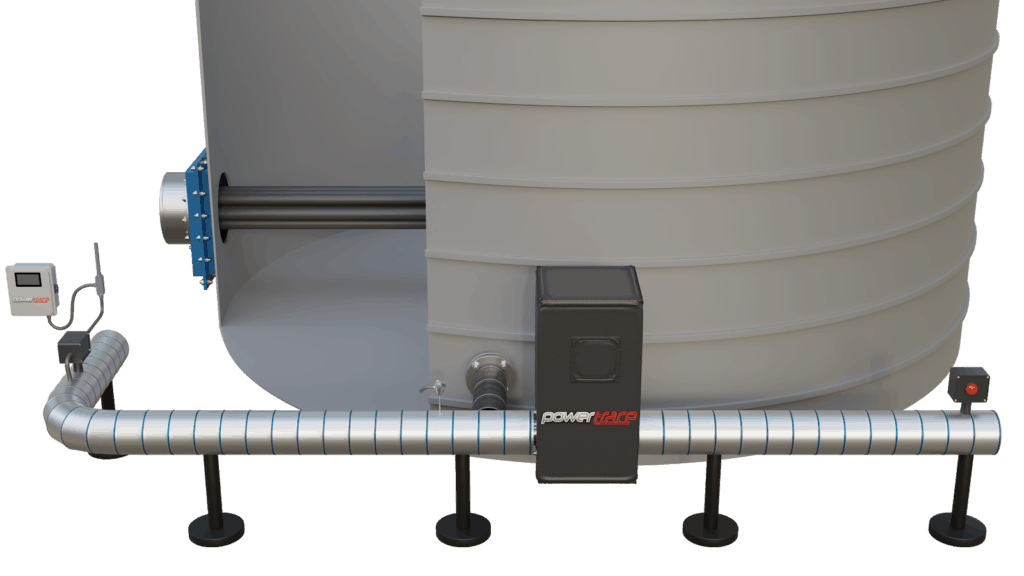

With reliable freeze protection from Powerblanket, you can rest assured your critical infrastructure will be ready for extreme weather. Explore our custom heat trace systems and discover the peace of mind that comes with a freeze protection system that is specifically designed by expert engineers to meet your every need.

While the inclement weather left some bewildered, many others knew that freezes weren’t an uncommon occurrence. These circumstances created a dialogue surrounding the need for emergency preparedness in vulnerable infrastructure. Failures in heat trace built to protect piping systems are an ever-present risk.

Heat trace and insulation have been used in factories, plants, and other processes for decades. While there is a common understanding that heat loss can be minimized using a combination of insulation and a heat source (like an electric heat trace), there is still a struggle with consistent failures causing a great deal of downtime.

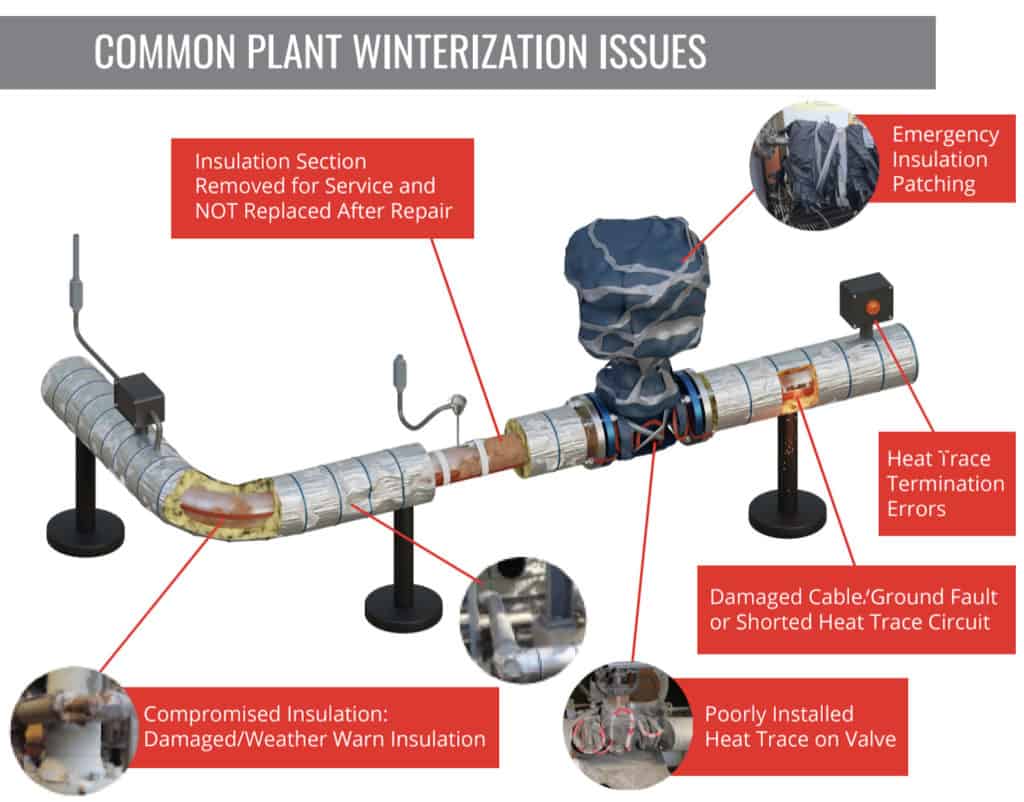

Here are some of the most common causes of failure in electric heat trace operations:

- Compromised insulation

- Improper reinstallation after temporary removal of insulation for servicing

- Errors in termination

- Ground faults or shorted circuits

While there are many more causes of failure, these are the most common. This article will explore each common cause in a bit more depth and offer an understanding of what can be done to avoid them.

Compromised Insulation

What does a failing heat trace system look like? Manufacturers will say that a working heat trace system is one that is pulling amps and creating heat. The issue lies deeper, however. If the insulation is wet, damaged, or otherwise compromised, the system as a whole will be useless, even if the heat trace is functioning properly. Compromised insulation jackets are as common as they are dangerous. Facilities that house heat trace systems are filled with workers. While accidents and cases of negligence are avoidable, they are bound to happen. Wrenches fall from scaffolds. Trucks sometimes back into piping racks. You know it as well as we do – sh*t happens. Once that outer insulation jacket is compromised, it’s no longer effective in protecting against heat loss. A loose jacket will allow moisture to creep in, rendering it useless. With an ineffective insulated jacket, a heat trace system can no longer do what it’s designed to do. When it’s time to zero out heat lost to ambient temperature, the pipe instead freezes.

Once an insulation jacket is compromised, it could take a long time to get it repaired. When time is of the essence, getting right to the problem’s source is vital. However, in usual business operations, and especially during heavy maintenance work, it can be difficult to find time to put that insulation back together correctly. These situations too often fall to the bottom of the list of priorities. Preventative maintenance in Texas during summer months for freeze protection systems falls to the bottom of that list.

Improper Reinstallation

Removable insulation jackets have long been a sensible solution to ongoing problems with damaged insulation. Removable jackets are easy to install, quick to repair, and should in theory be simple to reapply to a heat trace system. A lasting issue, however, is that when removing both insulation and heat trace elements is necessary, putting them back on correctly can be time consuming and frustrating. Both of these elements, the heat trace and insulation jacket, are separate parts that must be properly reinstalled. Damaged repairs requiring removal of insulation and heat trace systems leave too much room for incorrect replacement, if that replacement happens at all.

Powerblanket custom heat trace blankets offer ease and durability to insulated jacket replacement. With a heater integrated directly into the blanket, the entire blanket can easily come off and on vulnerable pipes. Powerblanket custom heat trace blankets are rated for Class 1 Division 2 areas. They are compliant with local codes, rugged, and flexible. The integrated Powerblanket solution is far more likely to be replaced correctly when compared to conventional heat trace methods thanks to its easy installation.

(Include picture of PB Valve Heater)

Errors In Termination

Incorrect termination of any electrical implement is an ever-present risk. Heat trace systems require a good bit of labor to correctly create a proper termination. Thoroughly install (or reinstall after servicing), double check, and QC those terminations regularly to confirm correct termination. reliable. There are plenty of resources for termination setup. Heat trace manufacturers provide thorough instruction, there are many tutorial videos found online via YouTube, or you can check out our blog posts on Heat Trace Systems to learn about termination in heat trace circuits.

Ground Faults & Shorted Circuits

Ground fault tripping can be caused by several different factors, including but not limited to:

- Short caused by damaged heating cables

- Heat trace circuits too great in length

- Underrated circuit breakers

- Failure to correctly QC heat trace during initial installation

So, then, what is the procedure for determining the cause of a known ground fault? The first step is to physically inspect the heat trace circuit. Look along the entire length of the installation to check for any signs of physical damage. It’s important to inspect the power and end seal termination kits to look for signs of a short.

Next, remove the power to the affected circuit. Then, use a megger to “Meg Ohm” or check for resistance to ground. Most manufacturers recommend using a megger with at least 500 vDC. If the heat trace circuit megs out, be sure to also meg the power wire from the heat trace junction box back to the breaker. This will ensure that there is no additional short in the power wire.

Self-regulating heat trace has an inrush for a short period of time at startup. This brief inrush could be two to three times the rated amperage. (Your 15amp circuit could be pulling 30amps or higher on a 30amp breaker.) To solve this, consider installing a heat trace controller with a soft start feature that will utilize thermal magnetic circuit breakers. These types of units can handle a much higher inrush for a few cycles, which could solve the issue quickly. Installing a higher amp rate breaker or shortening the heat trace run itself may also help.

As insulation and other electrical equipment can falter over time, consistently using a megger is vital for any facility dependent upon electric heat trace for production. While some may argue that voltage and OHM checks are sufficient, a megger is the only true way to test a heat trace circuit to ensure that it’s resistant to a ground. Those are important tests but will not provide the necessary assurance of a megger.

Finally, heat trace manufacturers recommend that all heat trace be QC’d when received, and checked again at these points:

- When first received at the facility, use a megger to check the insulation integrity to ground right in the box. Follow manufacturer instructors for the megger and heat trace. Most manufacturers provide a paper log with the cable. Ensure that observations are logged and dated.

- During onsite installation. Once the heat trace is cut to length and installed at its final destination, meg it and record the readings.

- After the trace circuit is insulated, but before final termination.

- During plan Plant Preventative Maintenance events, and especially some time (a few months is recommended) prior to colder weather.

Don’t let electrical heat trace failures get the best of you. Reduce downtime, protect your instruments, and remove the need for costly alternative heating solutions. Powerblanket offers straightforward solutions to assist you in protecting your production and materials. Explore Powerblanket heat trace products here and find a custom solution that offers freeze protection to your entire system. Powerblanket’s innovative design eliminates the hassle of tedious installation. Our heat trace system protection is designed by experienced engineers to bring ease to protecting your system. The PowerTrace Heat Trace system is designed with all of the above considerations in mind, offering you greater peace of mind and the long-term reliability you need.

Powerblanket Complete Thermal Solutions

Frequently Asked Questions

What is the best insulation for heat trace?

Self-seal rubber insulation is often considered the best option for heat trace systems due to its durability, energy efficiency, and ability to expand and contract with temperature changes, ensuring optimal performance and protection against heat loss.

What is heat tracing insulation?

Heat tracing insulation involves using materials like fiberglass to significantly reduce heat loss from pipes and vessels, enhancing the efficiency of heat trace systems by maintaining desired temperatures and preventing freezing.

How long does heat trace cable last?

Heat trace cables typically have a lifespan of 3-5 years, although their effectiveness can diminish over time, making regular maintenance and inspection crucial to prevent system failures.

What is the best insulation for keeping heat out?

Fiberglass is generally regarded as the most effective insulation material for keeping heat out, thanks to its excellent thermal resistance properties.

Don't let the cold weather stop your business. Powertrace heat trace cable will keep you running smoothly no matter how low the temperatures.