What is Heat Trace?

Are you having issues with busted pipes or frozen surfaces? Not particularly familiar with heat trace systems? You’re not alone. No need to worry, though. We’ll give you the details on everything there is to know about heat trace systems and heating cables.

For nearly a century, people everywhere have relied on variations in electric trace heating for temperature protection. Heat trace utilizes electricity and insulation to maintain or increase the temperature of pipes or other vessels, replacing any heat lost to outside temperatures. A heat trace system protects pipes and tanks from freeze damage while maintaining ideal temperatures to ensure that you never have to sacrifice efficiency to heat loss.

Existing initially as MI cables producing heat from electrical current creating resistance, this original technology lacked control and adjustability. Almost 50 years ago, we began to see the first production of “cut-to-length” trace cable made available. Between then and now, strides in technology have seen trace heating systems develop from mineral-insulated metal-sheathed cables (MI) to the self-regulating heat trace cables available today. Self-regulating heat trace cable offers a self-limiting and cut-to-length solution that makes up the bulk of today’s market. These heat trace systems offer solutions for anything from pipe protection to soil warming.

Inefficient heating processes can slow down production, costing you both time and money. Damaged products caused by freezing temperatures or improper heating are a painful mistake. Heat trace systems are built to make sure that mistake is never made.

The purpose of this article is to provide you with sufficient information to understand the basics of heat trace and its components and review best practices in the design of a freeze protection system.

Check out:

- Common uses

- How does heat trace work?

- What is self-regulating heat trace?

- How hot does heat trace get?

- Can heat trace touch itself?

- How long do the cables last?

Common Uses:

In the cold winter months, pipes transporting liquid substances can become vulnerable to freezing temperatures and increased viscosity. Heat trace is most commonly used to protect pipes from freeze damage during winter conditions. These systems are most often used to keep water from freezing, as water in any process or facility is critical.

Additionally, heat trace allows for optimal control of the flow and viscosity of transported liquids, allowing the user to regulate the temperature within pipes, in turn enhancing and streamlining your work.

Protecting pipes from freezing isn’t the only use, though. Here are some other common uses:

- Snow melt systems on sidewalks, driveways, and patios

- Keeping tank contents from freezing

- Helping instruments operate in more favorable ambient conditions.

Whatever your need is, an in-depth understanding of heat trace systems will help you select the weather protection option that is right for you.

We understand the unique challenges you face in your operations and environment. That’s why we provide fully customized heat trace systems designed specifically for your needs. Our engineers will evaluate every detail – from pipe layouts to insulation requirements – to create a reliable and efficient system to protect your assets.

How does heat trace work?

It’s a simple explanation for a common problem. If you’re dealing with pipes at risk of freezing, a heat trace system is your solution. An electrical element or heat trace cable (see pictures below) is fitted along the length of a pipe. This heat trace cable generates heat to maintain or increase the temperature of the pipe’s surface, and when installed with a good insulation system, you have a great solution.

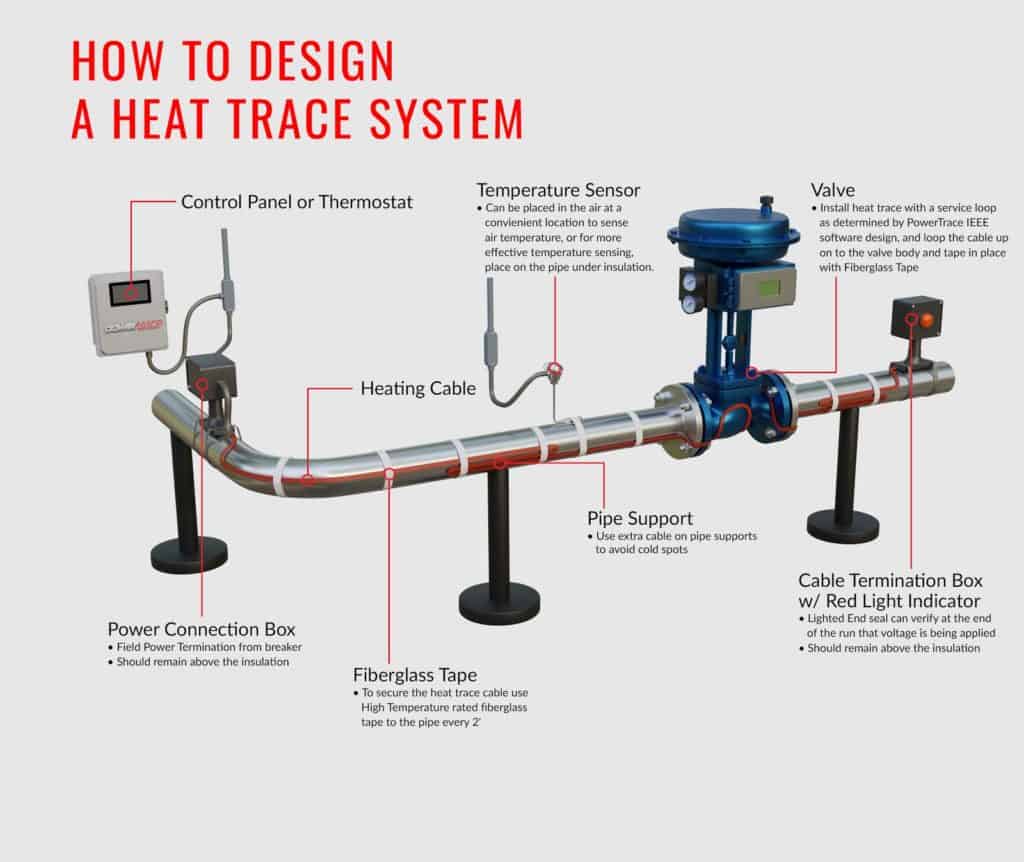

What does a typical heat trace system look like? A completed system begins at a power source. The heat trace cables are placed along the entire length of the surface of a pipe, sometimes held in place normally with a high-temperature 8tape. Once attached, both the pipes and heat cables are covered with an insulation jacket to minimize heat loss. Heat trace systems can be controlled with a simple thermostat or with a temperature sensor like an Rtd that provides feedback to a more common PID or PLC-style controller. These systems will control and adjust the temperature of the heat trace. Additionally, most are equipped with varying types of monitors to assist the user in observing power output. Most heat cables purchased independently can be cut to the desired length, then combined with termination and splice/tee kits2 to complete the system.

Note: Heat trace power output is measured by watts per linear foot. Heat trace voltages range from 120 to 277 Vac and from 3 to 20 watts per linear foot.

What is a Self-Regulating Heat Trace?

An important distinction to understand is the difference between constant wattage heat trace and self-regulating heat trace. In a constant wattage heat trace system, uniform and unchanging heat is delivered throughout the entire system. No matter the ambient temperature, the same amount of heat will be produced.

In a self-regulating heat trace system, the heat output is determined by the temperature of the surface where the heat trace is installed. A hotter surface will reduce the wattage output, a colder surface will allow more wattage to be produced. While the difference is simple, an understanding of each is important in determining which heat trace system is right for you.

Another advantage of self-regulating cable is that it can be overlapped on top of itself. When other styles of heat trace, like constant wattage or MI cable, overlap or touch itself, it will develop a hot spot and burn out. Self-reg cable will not do that.

So how does it work? Self-regulating heat trace technology automatically adjusts power output according to changes in the temperature to which it is attached. This technology begins on a microscopic level. The innermost part of the cable, referred to as the conductive core, is made up of carbon polymer that responds to changes in temperature.

When the surface temperature decreases, the core contracts, thus increasing the total number of electrical paths, subsequently increasing the temperature. Adversely, as the outside temperature increases, the core expands, decreasing the number of electrical paths and lowering the cable’s overall power output.

How hot does heat trace get?

Just how hot does heat trace get? MI Cable can maintain close to 1000 F, while constant wattage cables can normally maintain temperatures over 400F. Self-regulating cable will normally have two different offerings, ranging from 150 F to over 400 F, to maintain temperatures.

If you live or work in an area that often experiences sub-freezing temperatures, many of your basic common wattage heat trace cable options won’t reach sufficient temperatures to protect from frozen pipes. In very cold weather conditions, around 20°F or colder, heat cables struggle to prevent ice from forming.

Constant wattage heat trace systems vary in their wattages and power output. A common self-regulating heating cable will be able to accept voltages of 120, 208, 240, and 277 VAC., and will have an output of 3-20 watts per foot. Constant wattage cable will normally run on the same voltages but will top out at around 12 watts per foot. MI Heating cable can go up to 480V single phase and can actually go just over 1000 F.1

Can heat trace touch itself?

Constant wattage heat trace and MI cable cannot cross or touch itself. When a constant wattage heat trace is crossed over itself, the heat only increases. When applying constant wattage heat cables to your pipes or other surfaces, ensure that they do not cross and are spaced sufficiently. Self-regulating heat trace cables, however, would adjust to this temperature increase, making them safe to cross or overlap.

As with any electrical system, though, there are always potential dangers with using heat trace or heat cables. For the safest results, it’s best to have your heat trace systems professionally installed, whether you’re using heat cables or heat tape.

How long do heat cables last?

While the life expectancy of Thermon heat trace cables may vary due to external conditions and treatment, the heat trace cable will typically outlast the medium it is heating and/or the asset it is protecting. Other manufacturers however, will have varying levels of quality in their heat trace products, and could last as little as 3-5 years.

Here are a few tips for increasing the life of heat trace systems.

- Make sure your insulated jacket is efficient and well-fitted. A loose insulated jacket would increase the necessary power output and workload of the heat cable. No holes or gaps.

- Correctly install heat trace over valves, flange pairs, supports, and any other items along the pipe. See the manufacturer’s instructions…and follow them.

- Invest in thermostats and controllers. Even though it’s called self-regulating heat trace, it still requires some monitoring as it won’t turn itself on or off.

Still have questions?

Give us a call at (801) 506 0198. We’re happy to answer any questions you have to help you determine which heat trace solution best fits your needs.

Don't let the cold weather stop your business. Powertrace heat trace cable will keep you running smoothly no matter how low the temperatures.