Hot and Cold: Melting Points for Common Baking Ingredients

Welcome to Powerblanket, where new applications for our electric blankies pop up like daisies. Customers, including…bakeries? There is a long list of common baking ingredients that congeal, harden, thicken, freeze, or crystallize as temperatures drop. Many ingredients need heat to keep them liquid and transportable. What is the melting point of common baking ingredients?

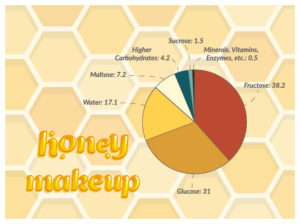

Runny Honey: What is Honey Made Of?

Honey is made of different complex and simple sugars, water, vitamins, antioxidants, enzymes, and minerals. These different parts lead it to eventually crystallize, which is an issue in bulk. To help you visualize, imagine having a 55-gallon barrel full of honey you have to bottle and ship out. If that entire honey drum has crystallized due to cold weather, are you going to scoop it out with a spoon and hand-squish it into every bottle? That would be both sticky and inefficient. The same goes for other products that harden or thicken and aren’t liquid enough to be poured or pumped.

Want to decrystallize honey or thaw other baking ingredients safely and gently? Check out our Bee Blankets, the ideal heating solution for your needs! Our Bee Blankets provide safe, even, low-temperature heating, perfect for delicate baking ingredients like honey or coconut oil. This customizable electric heating blanket lets you gently liquefy ingredients without damaging their quality.

Want to decrystallize honey or thaw other baking ingredients safely and gently? Check out our Bee Blankets, the ideal heating solution for your needs! Our Bee Blankets provide safe, even, low-temperature heating, perfect for delicate baking ingredients like honey or coconut oil. This customizable electric heating blanket lets you gently liquefy ingredients without damaging their quality.

Melting Point of Honey

Honey becomes almost impossible to spread or work with when it crystallizes (you’re probably familiar with the ole’ “pop the honey in the microwave” trick). When honey is crystallized, it’s melting point ranges between 104 and 122 °F (40 and 50 °C). This range accounts for the fact that the chemical makeup of honey will vary due to differences in bees, impurities, climate, flower supply, and geographical location of the particular hive.

Honey becomes almost impossible to spread or work with when it crystallizes (you’re probably familiar with the ole’ “pop the honey in the microwave” trick). When honey is crystallized, it’s melting point ranges between 104 and 122 °F (40 and 50 °C). This range accounts for the fact that the chemical makeup of honey will vary due to differences in bees, impurities, climate, flower supply, and geographical location of the particular hive.

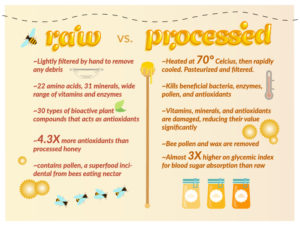

Raw vs. Processed

The FDA requires minimal straining for Honey to be considered “raw”. This indicates how important it is to heat honey with great care. Processed honey on the other hand, is blasted by high heat (161 ºF and higher!), straining, and pasteurization, which process removes wax, and destroys helpful yeast cells, enzymes, and antioxidants in raw honey.

Overheating honey destroys the properties of honey that are most nutritional for our bodies. Around 200 components, including antibacterial properties, are lost if honey is heated over 98.6 ºF (37 ºC). Higher than 104 ºF (40 ºC) and valuable enzymes are destroyed. In short, the danger of just sticking honey in a manufacturing microwave is denaturing, devaluing, and scorching it. Heating solutions for crystallized honey include generic electric heating blankets. However, these run the risk of scorching the honey, or overheating it. Because of this, it is crucial to heat and decrystallize raw honey carefully.

If you heat honey above 104 ºF (40 ºC), it will caramelize. For those apiarists and manufacturers that want to preserve their raw honey and still be able to bottle it, they need a specialized solution. The BeeBlanket maintains the temperature of a beehive, which preserves the valuable raw aspects of the honey, while warming it enough to liquify it. Warm honey makes it so much easier to bottle and jar honey.

Melting Point of Coconut Oil

Coconut Oil is used for a huge variety of purposes, not just for food. Depending on the makeup of your specific coconut oil, it melts at a temperature between 76-78 ºF (24-25 ºC). The melting point depends on how pure the oil is. Impurities spark crystallization. The purer the oil, the lower the melting point. Overall, at average room temperature and below, coconut oil is solid. Since coconut oil applications range from hair products to treating eczema, it is important that manufacturers package their coconut oil properly and accurately in a liquid state. Luckily, heating coconut oil back into liquid doesn’t affect the oil’s quality at all. The biggest issue is heating it slowly and evenly, so it doesn’t scorch.

Coconut Oil is used for a huge variety of purposes, not just for food. Depending on the makeup of your specific coconut oil, it melts at a temperature between 76-78 ºF (24-25 ºC). The melting point depends on how pure the oil is. Impurities spark crystallization. The purer the oil, the lower the melting point. Overall, at average room temperature and below, coconut oil is solid. Since coconut oil applications range from hair products to treating eczema, it is important that manufacturers package their coconut oil properly and accurately in a liquid state. Luckily, heating coconut oil back into liquid doesn’t affect the oil’s quality at all. The biggest issue is heating it slowly and evenly, so it doesn’t scorch.

Molasses Assets

Molasses is boiled down sugar cane, or sugar beet juice, dates, pomegranate, and sorghum. It will crystallize due to lowered temperatures or condensation. Molasses doesn’t freeze in any industrial grade freezer due to the sugar acting as an antifreeze to the water molecules. The water will evaporate out, leaving crystallized, grainy molasses. The key is to keep it at normal temperatures with light heat. Molasses is made primarily from sucrose, depending on the source: sugarcane, sugar beets, and sorghum are all sources from which molasses is made. The more sucrose, the more likely crystallization will occur. Slow, even heat will solve any crystallization problems. After fixing any problems with heat, molasses crystallization is less likely to happen again by adding citric acid or pure fructose.

Melting Point of Vegetable Oil

Believe it or not, oil congeals as it gets colder as well. The melting point of vegetable oils varies greatly depending on the type: sunflower oil and safflower oil (2 ºF, -17 ºC), canola oil (14 ºF, -10 ºC), olive oil and sesame oil (21 ºF, -6 ºC), peanut oil (37 ºF, 3 ºC) are just a few.

Believe it or not, oil congeals as it gets colder as well. The melting point of vegetable oils varies greatly depending on the type: sunflower oil and safflower oil (2 ºF, -17 ºC), canola oil (14 ºF, -10 ºC), olive oil and sesame oil (21 ºF, -6 ºC), peanut oil (37 ºF, 3 ºC) are just a few.

One company we work with ships vegetable oil overseas. They said, “In the winter, the oil congeals to a white residue because of the cold temperatures onboard the ship.” Like most problems with heating, they needed a solutions that would “heat the totes gently to get the oil back to its original consistency…” Keyword being gently. Uniform heat is important for warming oils and fats just like other food products. Scorching them or damaging their chemical makeup.

Melting Point of Shortening

Shortening is solidified, hydrogenated vegetable oil. When it comes to shortening (think Crisco), customers we’ve worked  with are more concerned with softening it than melting it. With a melting point of 117º F, it is almost always in its solid, fluffy form. This fat is often shipped in cold weather, where it will freeze and become rock hard. In order to get it ready to sell, it needs to be warmed with a slow, uniform heat to about room temperature (68-72 ºF).

with are more concerned with softening it than melting it. With a melting point of 117º F, it is almost always in its solid, fluffy form. This fat is often shipped in cold weather, where it will freeze and become rock hard. In order to get it ready to sell, it needs to be warmed with a slow, uniform heat to about room temperature (68-72 ºF).

Even though all of the products we’ve mentioned are different in composition and chemical makeup, they all add flavor to our food. To finally get to our table, it is important that manufacturers are able to transport them, and that means finding proper temperature solutions.

Sources:

Lindberg, Barbara. “The Bee Journal.” Why Does Honey Crystallize? January 01, 1970. Accessed November 19, 2018. http://thebeejournal.blogspot.com/2011/12/heating-and-freezing-honey.html.

Frequently Asked Questions

What temperature does honey melt at?

Honey melts at a temperature range of 104 to 122 °F (40 to 50 °C), and it is important to heat it gently to preserve its beneficial properties.

What is the melting point of pure honey?

The melting point of pure, crystallized honey is between 104 and 122 °F (40 and 50 °C), depending on its composition.

What temperature kills yeast in honey?

Yeast in honey is killed at 125 °F (52 °C) in 8 hours, 145 °F (63 °C) in 30 minutes, and 160 °F (71 °C) in 1 minute, which is why careful heating is crucial to maintain honey's quality.

What temperature spoils honey?

Honey begins to degrade at temperatures above 104 °F (40 °C), and it can spoil or "burn" at temperatures between 160 and 180 °F (71 to 82 °C).

Temperature control when working with coconut oil is key, take a look at our game-changing Coconut Blankets.