*Note – This is the fourth article in our series on the thermal loop. See the bottom of this article for all posts in this series.

On/Off temperature control is the most common and widely used method of controlling a thermal system bar none. That’s how your home air conditioning and heating system is controlled, your oven, your water heaters..in fact 50% of all of the electric load in the US is from thermostatically controlled loads

When it comes specifically to controlling a heating or cooling system in industrial applications, thermostats still dominate the control scene. Mostly due to low expense points and ease of use. Temperature sensor types can vary, but most often a mercury filled bulb and capillary system or a bi metallic snap disc style unit is used. Other sensors like thermistors, thermocouples or RTD’s can also be used as sensors for On/Off Controllers. No matter what sensor type you use, the modulation of on off controllers is not precise enough for many applications. Regardless of manufacturer claims, when installed in an industrial process, on off controllers can only deliver around +/- 2-5% accuracy. If precise or very tight temperature control is your goal, proportional or PID control would be a better choice. We discuss those in some of our other blogs (Here) (and Here)

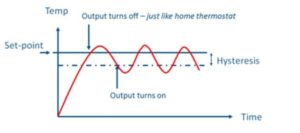

The name On/Off comes from the method of sending the signal to cool or heat: the system is on or it is off. It’s pretty simple. A set point is entered into the controller, and when the process variable or set point is below that set point, the controller drives the contact closed and energizes the loop, and when it’s above that set point it turns it off. These systems work well and have been used for over 100 years. Temperature swings are bigger, and these on/off systems are not recommended for systems needing precise temperature control. Swings of 2-5% or greater can be had above and below the temperature set point.

(Photo Credit: https://www.west-cs.com/news/understanding-on-off-temperature-controllers/)

On/Off control is fantastic for low cost low precision systems. Many times these controller types are used to drive larger loads. This on off method of control can be used to drive a wide variety of wattage and amps too. One common use is called pilot duty mode. In this method, the thermostat drives a contact closure to what is called a coil on a relay. That relay then is energized and the load is offered to the process. On Off systems utilizing thermostats can normally only drive lower single phase voltages with a max amperage of just over 20 amps. But when utilizing a thermostat in on off mode to drive a coil, much larger 3 phase higher amperage loads can be driven.

Here at PowerBlanket, we are on/off temperature control experts. Nearly every blanket we sell is controlled that way. We also deeply understand proportional and PID control as well, and would be glad to help in any way as you decide what is best for your process. Give us a call today and let’s talk.

The Thermal Loop Series

2- What is a Temperature Controller and How Does It Work?

5- Proportional Control in the Thermal Loop

Frequently Asked Questions

What is the on-off level control system?

The on-off level control system is a basic automatic process control method that switches outputs fully on or off based on a process variable, without intermediate settings, making it cost-effective for simple applications.

What is the on-off control strategy?

The on-off control strategy involves switching a system component, like a heater or cooler, fully on or off based on a set threshold, such as a specific temperature or energy storage level, to maintain desired conditions.

What are the disadvantages of on-off control system?

The disadvantages of an on-off control system include continuous switching around the setpoint, potential significant deviation if hysteresis is not properly set, and lack of precision compared to more advanced control systems.

What are the two types of control systems?

The two main types of control systems are open-loop systems, which operate without feedback, and closed-loop systems, which use feedback to adjust and maintain the desired output.

Powerblanket's industrial control solutions give you the power to automate, remotely control, and monitor your valuable materials and equipment.