The Little Blanket that Could: Powerblanket Bucket Heaters

What can you put in a five-gallon bucket? Five gallon buckets can house everything from soap oils to baseballs for a little league practice. If your bucket stores temperature-sensitive products, a Powerblanket 5 Gallon Bucket Heater could very well be your new favorite accessory. Bucket heaters and pail blankets are excellent solutions for freeze protection, improved viscosity, and general warming.

Actual Amazon Reviews

Consumers use the Powerblanket Bucket Heater for a variety of applications. This is a versatile, safe, and easy heating solutions for buckets and pails.

Warming Water for a Greenhouse

“I actually use this for a very unusual purpose. I raise bonsai, and have to winter some of them in a small vinyl greenhouse. The greenhouse naturally maintains a temperature only about 4 degrees above the outside temp. So far we’ve had a very cold season, and its only January!

Finding a safe, inexpensive way to keep the temp in the greenhouse above freezing, has been a challenge. It’s a very humid environment, so electronics have to be sealed. Gas or propane is not good either. I found this, and to put it around a sealed 5gal pail of water. The heated bucket consistently puts off enough heat that I think my trees my survive the winter. It’s not a perfect solution, but it’s the best I’ve found short of building a serious greenhouse.”

Auto Detailing

“Use this on my auto detailing, nice to put hands in warm water when cold out.”

Making Soap

“Love this thing!!! This is for warming my soaping oils, and it’s marvelous. I have it wrapped around my buckets and at around $100 it’s way more cost effective than using the water heated tanks (which are like $800). More of these are in my future.”

Another customer said, “I use this for making soap. My recipe has a large amount of hard betters and I would have to reheat the entire bucket a small pot at a time and mix it all back in to make the oils ready to soap with. Now all I do is plug this in and wait a few hours, while I can do other things, and my oils are ready to go! I love this thing, and will probably buy more. I wrapped it around a 5 gallon bucket I reused from some bulk oil I bought.”

Thawing Frozen Buckets

“This thing is exactly what I have been looking for. My Powerblanket heats up to a perfect temp, and I can go about my day without worrying the shop is going to burn to the ground while leaving the jugs unattended. If you need to thaw a bucket and thaw it fast without loss from evaporation this heater is THE ONE!”

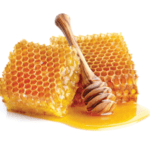

Improving Honey Viscosity

One customer reported, “Really worked great on my bucket of granulated honey. Just enough heat to clarify it in 6-8 hours. this blanket is not hotter than hot water. The honey ends up warm not hot. Even better than a light bulb for even heating.”

Another said, “I’m just a small amateur beekeeper looking for a good way to warm my 5-gallon pails of honey safely and efficiently. So when I spotted the BeeBlanket on Amazon it looked like something that might work well for me.

My order arrived quickly (thanks Amazon Prime) and after a quick inspection, I put it to use. After 24 hours my honey went from 62°F to a nice 104°F in a room with an ambient temperature of roughly 68°F throughout the process. Also, I placed my cold pail on a chunk of ridgid foam insulation to minimize heat transfer from the cold floor.

Admittedly I haven’t warmed a stone-cold pail of crystallized honey with it, that will be later. Warming and re-liquefying a 5-gallon pail of honey would be a multi-day project in my estimation. Slow and steady like the bees…

So far I’m impressed with the BeeBlanket and it’s working good for my purposes. 104° honey is easy to strain and bottle plus it’s safe for the honey! Using a 120 watt insulated blanket seems efficient to me and it worked quite well. After running my BeeBlanket for a full 24 hours on a cool bucket of honey my Kill-A-Watt meter gave me a daily cost of 0.08/day for an operating cost. (Power rate here is 0.102/kh) Seems like that’s a pretty reasonable way to warm 5 gallons of honey. I’m sold on this!”

Warming Paint

“These Powerblankets have been exactly what we needed to heat up the buckets of paint we have stored in the garage. We’re working on a remodeling project right now that’s taken longer than expected and some of the finish work, like painting, is going into the winter months. We’re not in a position where the buckets of paint can stay inside all the time when not being used, so they frequently go back outside in the garage and into the cold. Rather than having to wait hours for the paint to warm up on its own and thin to a workable temperature each time we bring some in, we just put one of these Powerblankets around the bucket and it works like an electric blanket or heating pad, heating the paint. Works great!”

Warming and Protecting Coconut Oil

“Whether you have a camp, cold storage or outdoor kitchen, this warming blanket is ideal for keeping coconut oil ready to use. My brother belongs to an organization that sponsors dinners throughout the year. This year many of them have been scheduled for the chillier weather in the fall and winter. He donates the oil. First outing they did not account for the time necessary to to heat the oil leading to delays and grumbling. This blanket has remedied that. It is easy to use. the buckle and strap system ensures a snug fit. The thermostat is preset so the oil is heated without getting too hot. Simply position, plug in and use. I would prefer a power button and adjustable thermostat but those niceties are not essential to the usefulness of this blanket. it can be used on any variety of items that solidify when cold. We are completely pleased with its quality and performance.”

The Real Cost Savings

Perhaps you’re thinking: how much is it going to cost me to wrap my buckets in a heating solution? It will cost you much less in the long run. If you use band heaters or crank up the ambient temperature around your buckets and pails, you will lose a lot of energy to inefficiency. With Powerblanket bucket and pail heaters, you get an even distribution of heat without sacrificing efficiency.

Powerblanket bucket heaters are more efficient than the traditional band heater, without running the risk of overheating or burning the product in your bucket. What’s more, with the Powerblanket solution, you have the ease of use that comes with a thermostatic controller. With our Pro Series heaters, the temperature adjusts from ambient up to 145° F. And with the RR Series, you can adjust the heat anywhere from ambient to 100° F. The Powerblanket solution offers both versatility and flexibility.

Features of Powerblanket Bucket Heaters:

- The warmers are easy to install and remove.

- The full wrap-around design ensures equal heat distribution and proper insulation.

- The design prevents product waste to temperature-sensitive materials by maintaining consistent storage temperatures.

- Powerblanket® GreenHeat™ Technology uses less energy and saves you money in the long run.

Whether you’re storing paint, water, food, or industrial supplies in buckets, those buckets will need to be protected from the cold. Of course, you can address this problem by keeping your product in a heated warehouse, but if the warehouse is large and you are storing a lot of product, it’s going to cost a lot to keep the temperature of the ambient air high enough that your buckets don’t drop below their ideal range.

Frequently Asked Questions

What is the perfect bucket heater?

The ideal bucket heater is one that efficiently maintains the desired temperature for your specific application, such as Powerblanket bucket heaters, which offer even heat distribution and energy efficiency.

Do immersion heaters use a lot of electricity?

Immersion heaters can be energy-intensive, typically using around three kilowatts per hour, but Powerblanket heaters are designed to be more energy-efficient, reducing overall electricity consumption.

Are bucket heaters safe?

Bucket heaters are safe when used correctly, especially when plugged into a ground-fault circuit interrupter (GFCI) outlet to prevent electrical hazards.

What are bucket heaters used for?

Bucket heaters are versatile tools used for applications like warming water, improving honey viscosity, thawing frozen materials, and maintaining the temperature of various liquids and materials.

Maintain the temperature of your food, water, or industrial supplies with an effective and affordable bucket heater from Powerblanket.

The Bee Blanket was designed specifically for heating honey properly. When you employ other heating solutions to heat honey, you run the risk of overheating, and overheating is no small problem. Honey that’s been overheated will crystalize faster and is harder to work with. But ease of use is not the only concern. In fact, the biggest concern with heating your honey past its ideal temperature is the negative effects it has on the nutritional value of the honey.

The Bee Blanket was designed specifically for heating honey properly. When you employ other heating solutions to heat honey, you run the risk of overheating, and overheating is no small problem. Honey that’s been overheated will crystalize faster and is harder to work with. But ease of use is not the only concern. In fact, the biggest concern with heating your honey past its ideal temperature is the negative effects it has on the nutritional value of the honey.