Wet Tile Saws

Wet tile saws are essential tools for cutting ceramic tile, porcelain tile, and stone. These electric table saws do not technically use a blade at all, and instead use a diamond coated grinding wheel. Water is pumped continuously both over the wheel and over the material being cut. Not only does this water source keep the grinding wheel from overheating, it produces a cleaner chip free cut while reducing dust and debris. Wet tiles and stones are less brittle and easier to cut. This results in a cleaner, fresher cut than if you were using a dry tile cutter.

External Bucket Reservoirs

Even though wet tile saws include a water reservoir tray at the base of the saw, many professionals find it more efficient to place their pump into a clean 5 gallon bucket. Using an external bucket reservoir makes it easier to keep clean water entering the pump instead of using the sediment filled run-off. 5 gallon buckets significantly increase your water capacity as well so you can cut for longer without refilling. Most find them easier to fill, drain, and use than reservoir trays.

Winter Tile Cutting Problems

Operating a wet tile saw during the winter presents obvious challenges. When the temperatures drop, so do the temperatures of your water reservoir. Cutting tile after tile with frigid water pouring around your hands and spraying around your face is a miserable way to complete a project. Plus when the temperatures drop below freezing, reservoirs, pumps, and supply lines freeze up which renders your wet tile saw useless.

Tiles and stone also become more brittle in cold temperatures. It is important to find a warm location to store your materials to reduce costly waste and produce higher quality results. Keeping your tiles, stones, grouts, and mortars at warm temperatures makes them easier to cut, produces better cuts, and makes them easier to set, install, and cure.

Past Solution Attempts

Desperate to avoid costly downtime during a winter off-season, tile and stone cutters have turned to many different methods in the past to keep their wet tile saws running during the winter months.

Move Inside

On paper, the idea to simply move your cutting station inside is very tempting. However, most professionals have found that clients, home owners, and other sub-contractors cannot tolerate the mess that accompany wet tile saw operation. Even if you attempt to contain the messy run-off, it is very difficult to control all the spray and mist exuding from the saw itself. Some construct time-consuming wet saw tents or use plastic kiddie pools to try and contain water output but…spoiler alert…water still gets everywhere.

Chemical Additives

Others have tried adding window washer fluid, anti-freeze, or even alcohol to their water reservoir to prevent freezing. However, working with frigid water constantly streaming over your hands and misting your face is a real productivity buster. Not to mention inhaling antifreeze mist is not the safest way to work. Chemical additives produce another negative side effect. The chemical residue they leave behind on every single tile and stone prevents thin-set mortars from bonding when it comes time for you to actually set them.

Immersion Heaters

Immersion heaters are metal heating rods or coils that can be inserted into your water reservoir. These heaters do not have thermostatic controls and will continuously heat the water as long as they are plugged in. Overheating your water reservoir can not only damage your pump but produce temperatures that are painful to work with. Babysitting your heater is no way to stay productive on the job-site. Some immersion heaters are also unsafe to use in poly or plastic buckets due to the fact that as the water level drops they can come in contact with and melt your bucket.

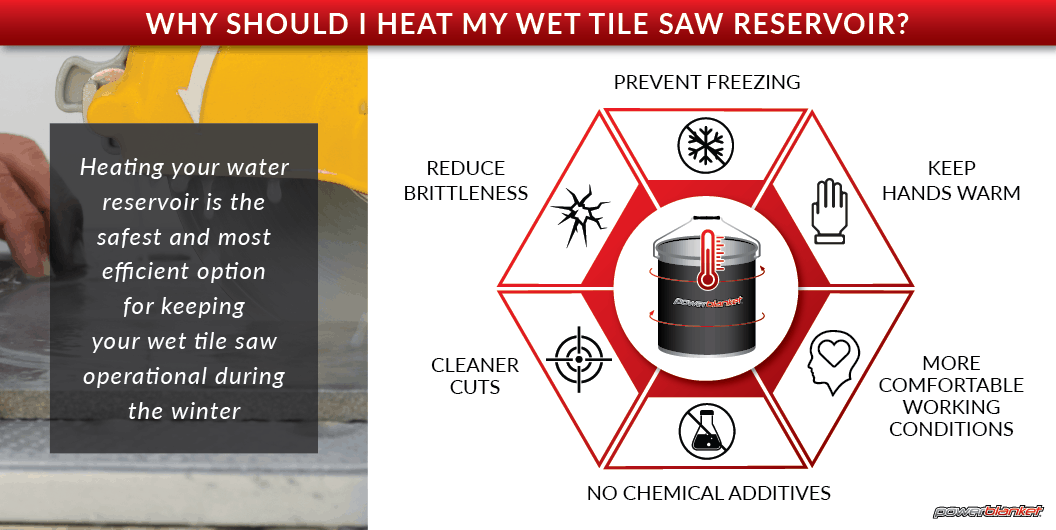

Finally An Effective Solution: Bucket Heating Blankets

Heating your water reservoir is the best method for keeping your wet tile saw running all winter long. Warm water reduces material brittleness and produces better, cleaner cuts. Heated water will also keep your hands warm while cutting, thus increasing your productivity. However, not all bucket heaters are created equal. Externally wrapping your bucket reservoir with an electrically powered, insulated heating blanket is a safer and more energy efficient heating method than immersion heaters.

Powerblanket Winter Tile Cutting Solutions

Powerblanket specializes in winter construction solutions. We pride ourselves on engineering safe, efficient temperature control products for every project. We can protect your tools and materials, save you time and money, and get you back to work.

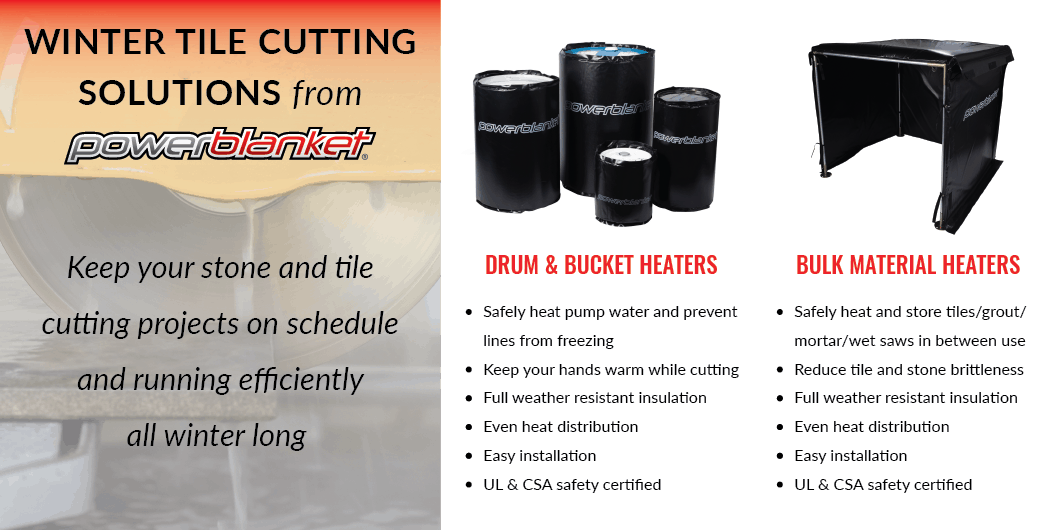

Bucket Heaters

Our heavily insulated bucket heating blankets distribute even, consistent heat around your entire water reservoir. By eliminating hot and cold spots you can be sure your water temperature is comfortable. Our bucket heaters allow you to regulate your water reservoir temperatures without babysitting your equipment to avoid overheating. Portable and easy to install, they will save you time and money and get you back to cutting all winter long.

Drum Heaters

Increase your wet tile saw’s duty cycle by using a larger water reservoir for bigger projects. Upgrade to a drum or barrel reservoir and Powerblanket has you covered, literally. Our heavy duty, fully insulated drum and barrel heaters will keep your water reservoir temperatures exactly where you want them.

Hot Box Heaters

Cutting cold tiles and stone can cause your materials to shatter. Luckily, Powerblanket has just the answer. Our Hot Box bulk material warmers provide even, consistent heat to everything stored within. Avoid unnecessary waste and ensure your grouts, mortars, tiles, and stones are safe and ready to use by storing them in a warm, weather protected enclosure. Hot boxes are portable and easy to install and use in storage facilities, work vehicles, or on job sites.

Allow Powerblanket to eliminate the “off-season” and help you work comfortably and efficiently no matter what mother nature throws your way. Contact us at 855.972.2314 or [email protected] to find the perfect solutions for your winter construction needs.

Frequently Asked Questions

What is the best tool to cut tile?

The best tool to cut tile is a wet tile saw, which uses a water-cooled diamond blade to make precise, chip-free cuts on ceramic, porcelain, and stone tiles.

Is it better to use a tile cutter or wet saw?

A wet saw is generally better than a tile cutter for intricate shapes and harder tile materials, as it can create curved cuts and handle the toughest varieties of tile.

How do you cut tile with a wet saw without chipping?

To cut tile with a wet saw without chipping, use painter's tape on the cutting lines and start by making a small notch before completing the cut.

How big of a tile can a 7 inch tile saw cut?

A 7-inch tile saw can typically rip tiles up to 20 inches and diagonally cut tiles up to 13 inches, handling materials like ceramic, porcelain, and stone up to 1-1/4 inches thick.

Maintain the temperature of your food, water, or industrial supplies with an effective and affordable bucket heater from Powerblanket.