If your product will become compromised as the temperature of the ambient air drops below freezing, then a barrel heater is a simple solution to your dilemma. But what else can you do with a barrel heater? Most are aware that drum and barrel heaters keep products from freezing, but many are unaware of their other diverse functions.

The Barrel Heater: A Versatile Product

In the United States, during summer nights, temperatures can get as low as the 50s ºF. This really isn’t that cold, but in the case of highly sensitive chemicals and other finicky materials, this could lead to ruined, wasted product–and ultimately huge profit losses. In case you’re new here: lost money = bad.

Take a look at these six ways to use a barrel heater:

1. Melting and Preheating

If you have a product that needs to be brought from a highly-viscous or solid state to a liquid, a barrel heater might be your golden ticket. What you don’t want to have to do is transfer the product from its storage unit to some melting device. With an adequate barrel heater, you can melt and preheat your product to whatever temperature you need, while keeping it in the same barrel you store it in. Many food products can benefit from this.

One of Powerblanket’s customers is a soap maker who uses barrel heaters to warm up his soap oils for use every day. The barrel heater allows for slow, controlled heating without the danger of scorching product. The soap maker has found Powerblanket’s barrel heater to be the most efficient soap oil warmer on the market.

2. Temperature Maintenance

Maybe your case is a matter of temperature maintenance instead. This is often the case with certain resins, epoxies, and spray foam, even during storage. A drop below ideal temperature could compromise the nature of certain chemicals and other liquids. For example, epoxy must be stored at a specific temperature. If the epoxy gets too cold, it won’t be able to react with other chemicals for use later on. Barrel heaters prevent that from happening by providing consistent, evenly spread heat while in storage.

3. Viscosity Regulation

This use case is akin to the idea behind melting and preheating your product. If you have a product that needs to remain at a high temperature to avoid becoming too viscous, then you could drastically benefit from a product like a drum heating blanket. Diesel Exhaust Fluid, better known as DEF, needs to be kept at a temperature above freezing to prevent it from thickening and lessening its efficiency in diesel engines. Barrel heating technology allows DEF to stay above that point, taking that worry away from the minds of truckers and other large vehicle operators.

4. Chemical Reaction Enablement

What if you could use your storage barrel or drum for chemical mixtures that need a certain level of heat? Well, you can. Barrel heaters can be very useful in providing heat for chemical reactions. One such product is epoxy. Epoxy must be heated to a specific temperature before mixing with other chemical reactants. Barrel heaters can be utilized to reach that temperature within a quick amount of time, getting the reaction going and the epoxy ready for use faster than using other options.

5. Decontamination

In order for some liquids and resins to keep from becoming contaminated, they have to constantly sit at higher temperatures than room temperature. If this is the case with your product, you can easily accommodate this need through the application of an efficient barrel heater.

Barrel Heating Technology from Powerblanket

Barrel heaters have uses in virtually every industry. Powerblanket meets all barrel heating needs through its vast array of heating blankets:

- barrel heaters

- bucket warmers

- drum heaters

- bee blankets

- tote heaters

- spray foam heaters

- wax heaters

- coconut oil warmers

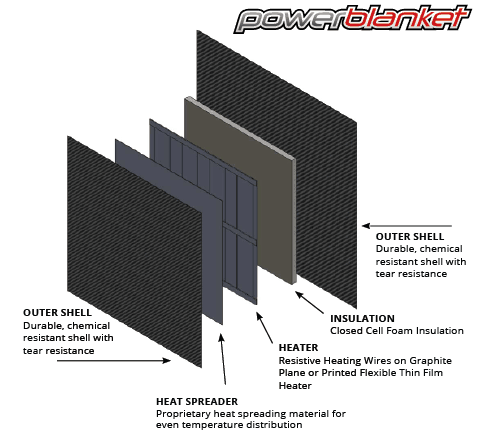

Each Powerblanket product comes in multiple sizes and power ratings, as well as being ETL certified to UL & CSA safety standards. Easy to set up and simple to use, Powerblanket’s heating blankets offer complete temperature control.

Check out more information about Powerblanket drum and barrel heaters by clicking here.

Powerblanket's industrial drum & barrel heaters provide even and consistent heating, eliminating waste and lowering costs.