Laying Bricks In Cold Weather

Work during winter conditions can be extremely difficult. Luckily, there are some cold-weather construction solutions that will save the job without breaking the bank and keep the work progressing regardless of the temperature. There are many crews that choose to shut down certain operations until warm weather returns. One such construction project that is difficult to accomplish during winter is bricklaying.

According to Masonry Magazine

“It is definitely harder to do masonry in cold weather, but it can be done and money can still be made as long as you cover your bases.”

With Powerblanket’s innovative heating solutions, laying bricks in cold weather is easier than ever. Our ground thaw blankets provide deep, even thawing to prepare your site for stable masonry work. Bulk material warmers allow you to easily transport and store mortar, sand, and mixes at ideal temperatures, ready for immediate use. Our concrete curing blankets promote proper curing regardless of weather for a strong, lasting mortar bond.

Winter Masonry Problems

Let’s take a closer look at the potential problems of laying bricks, blocks, and other masonry units in cold weather.

Frozen Ground

Frost line depth can be a real hurdle to overcome before laying bricks. During the winter, ground can heave and settle which creates a very unstable surface for masonry work. Laying warm, fresh mortar onto a frigid surface will cause thermal cracking and curing problems.

Cold Ingredients

Mixing mortar with heated materials or admixtures improves its strength and plasticity. Water, sand, or both can be heated for use in mortar in cold weather. However, heating prepackaged materials such as cement and hydrated lime have long been a problem for brick masons.

Mortar Curing Problems

The primary problem with laying bricks in cold weather is the mortar. Cold temperatures slow the hydration of cement in mortar mix and lengthen cement curing time. Bricks and other masonry units require fully cured mortar in order to be strong enough to continue building around them. Mortar mixed during cold weather also has lower water content, increased air content, and reduced early strength compared with those mixed during normal temperatures.

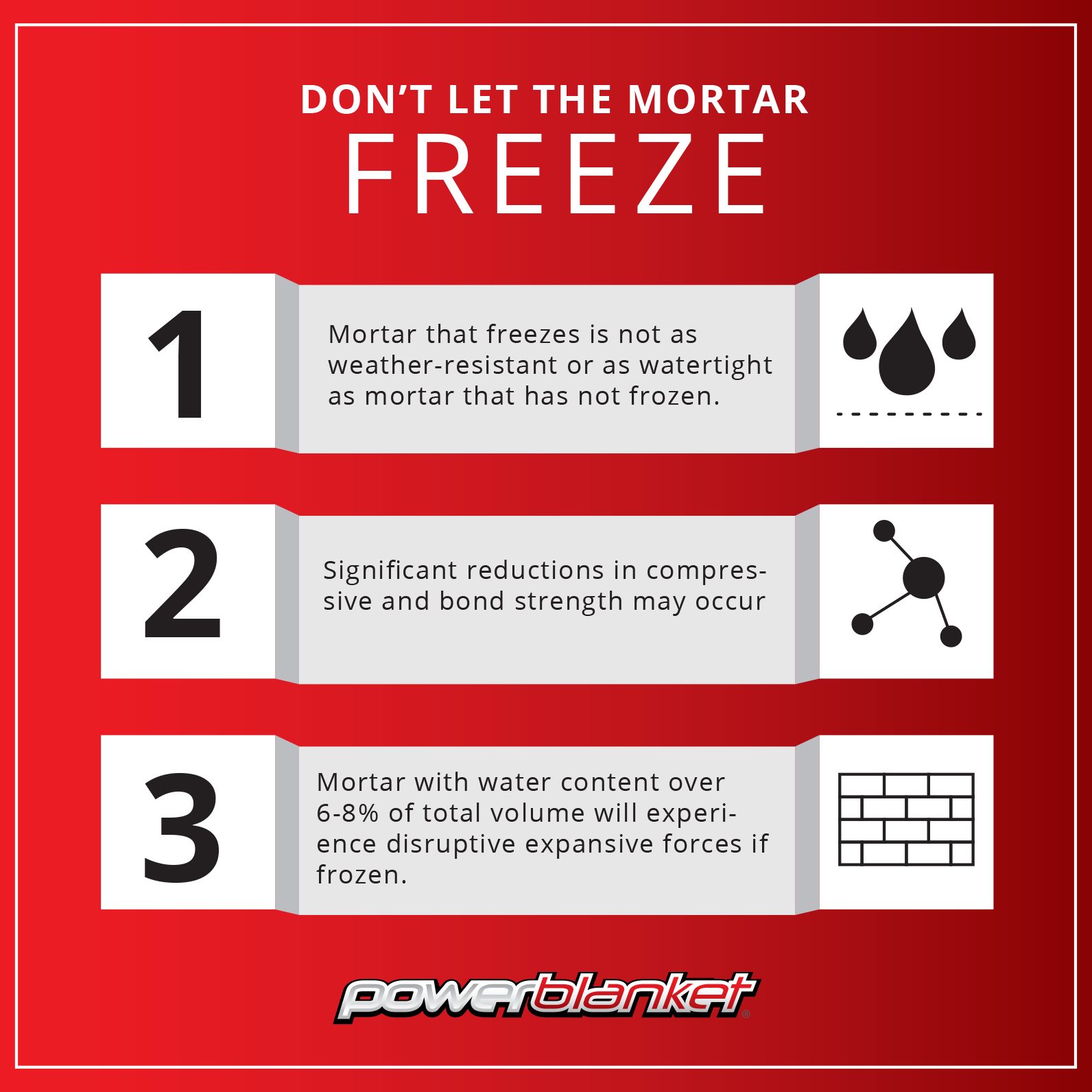

Mortar should never freeze because it will not be weather-resistant or watertight. In addition, significant reductions in compressive and bond strength may occur. Mortar with water content over 6-8% of total volume will forcefully expand if frozen. Because water increases in volume when it freezes, the bond between the brick or block and the mortar can be damaged or destroyed.

Powerblanket Winter Masonry Solutions

Ground Thawing Blankets

Before you even begin to lay masonry units, your ground and subgrade should be warmed and prepped. Some crews try laying down insulation or building enclosures around their site to try to thaw sub-grade. These methods are inefficient, time-consuming, and will not provide the heating power necessary to adequately thaw and start building. Ground thaw blankets from Powerblanket provide deep and even heating to the most stubborn frozen sub-grade.

Bulk Material Warmers

Whether you need a means for protecting temperature-sensitive materials in storage or you need a heating solution for onsite temperature maintenance, consider the Powerblanket Hot Box. This versatile heating solution accommodates remote-location use, job site heating, and the transportation of temperature-sensitive materials. Imagine transporting materials from job to job, knowing that your mortar, sand, and/or dry mixes will be ready for use when you arrive and well into the day.

The revolutionary design of Powerblanket Hot Boxes provides uniform heat to all materials stored inside. This reduces the chance of having any hot and cold spots. If stored properly, masonry materials, chemicals, industrial products, and temperature-sensitive materials will last longer and be more effective.

Concrete Curing Blankets

Powerblanket concrete curing blankets eliminate the need for heated enclosures and are the best option when it comes to curing. They maintain the proper curing temperature no matter what changes in weather occur, keeping the mortar bond strong and lasting. Don’t waste time building enclosures. Concrete curing blankets easily hang on newly laid walls and will quickly cure your mortar to a strong, durable finish.

Contact Powerblanket today to find the right winter masonry solutions for your needs at 855.524.2695 or [email protected].

The Powerblanket Hot Box is the perfect solution for your bulk material heating needs.