Epoxies have improved how we build just about everything. They have improved the way industries world wide adhere, reinforce, insulate, coat, beautify, and strengthen. Let’s take a look at what epoxies are, how they work, their varieties, and how Powerblanket can be your epoxy curing partner.

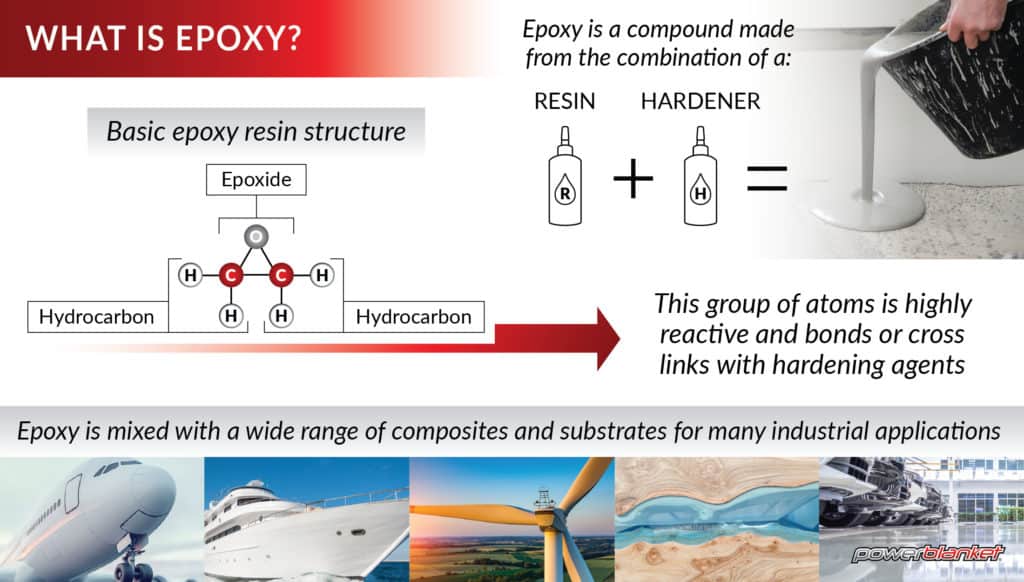

What is Epoxy?

Epoxy is a reactive compound that consists of an epoxy resin and a curing agent or hardener. It begins with a basic epoxide structure which consists of 2 hydrocarbons bonded to a single oxygen atom. These atoms contain highly reactive bonding sites that allow them to bond with a wide range of substances.

Epoxides will react with almost anything, which means they react very well with hardening agents to cure into a strong finished material. Epoxy can be combined with a wide range of composite materials and other substrates for industrial applications that require:

- Durability (low degradation)

- Low shrinkage

- Flexible strength

- Excellent adhesion to substrates

- Electrical insulation

- Chemical and solvent resistance

- Moisture resistance

A Brief History

The first documented scientific investigations into epoxy reactions began in several countries (United States, Switzerland, Germany) shortly before World War II. These experiments were not very successful and it took several years for the first actual patent to be filed. A US scientist, Caston Greenlee secured the first patent for a commercial epoxy resin in 1943 but did not start manufacturing until 1947, when the war was over.

Other manufacturers began to realize that epoxy bonded extremely well to a variety of surfaces and could be used for coatings, adhesives, reinforcements, and more. Over the years, people have experimented with different fillers and additives to make epoxy an even more versatile tool.

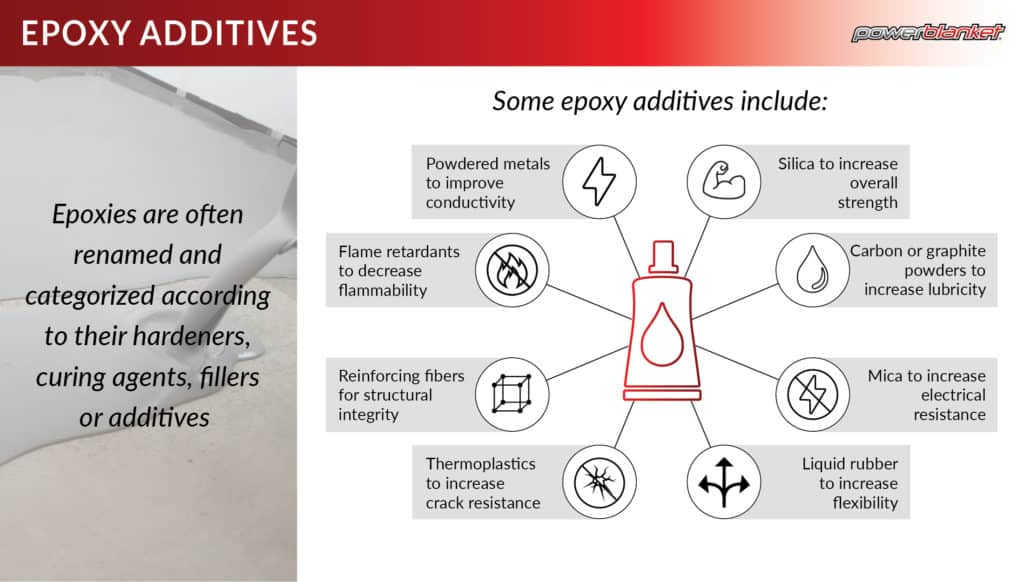

What are Epoxy Composites?

Because of its ability to bond and cross link with a wide range of materials, epoxy can be combined with different additives and fillers to increase its performance and versatility. Epoxies will often get renamed according to its additives. Some of these additives include:

- Reinforcing fibers (graphite, glass, polyaramid) to increase structural integrity

- Powdered metals (to improve thermal and electrical conductivity)

- Silica (to increase strength)

- Mica (to increase electrical resistance)

- Carbon and graphite powders (to increase lubricity)

- Liquid rubber (to increase flexibility and crack resistance)

- Thermoplastics (to increase crack resistance)

- Flame retardants (decreases flammability)

Powerblanket Epoxy Curing Solutions

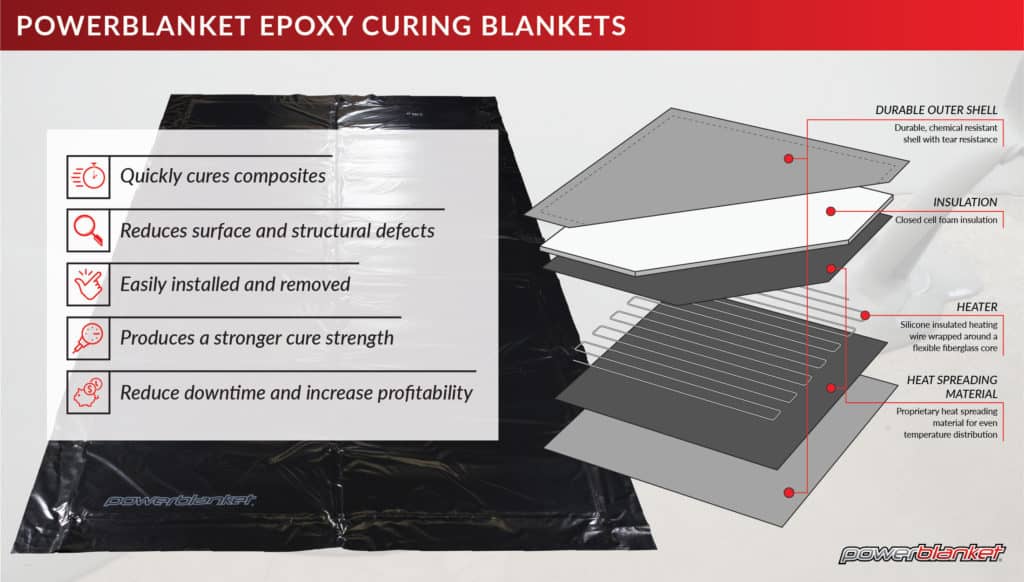

Powerblanket began our industry leading journey right here, with curing. We set forth to solve cold weather problems and help companies quickly cure to a maximum strength all year long. Our heating blankets not only keep epoxy at optimal temperatures for curing, but also preheat substrate, protect epoxy during curing, reduce costly downtime, and quickly cure to a stronger finish.

Powerblanket epoxy curing blankets contain our patented heat spreading technology to eliminate hot and cold spots for an even cure. With a durable, heavy duty, vinyl shell, they are perfectly suited for outdoor or indoor projects. Improve the look and strength of your epoxy and cure to a quicker and stronger finish with epoxy curing blankets. Contact us today for find the perfect epoxy curing solutions for your needs.

Powerblanket epoxy curing blankets contain our patented heat spreading technology to eliminate hot and cold spots for an even cure. With a durable, heavy duty, vinyl shell, they are perfectly suited for outdoor or indoor projects. Improve the look and strength of your epoxy and cure to a quicker and stronger finish with epoxy curing blankets. Contact us today for find the perfect epoxy curing solutions for your needs.

Frequently Asked Questions

What is epoxy and what is it used for?

Epoxy is a versatile compound used for its strong adhesive properties, making it ideal for applications such as repairing broken objects, creating sealants, and enhancing structural integrity in construction and manufacturing.

Is epoxy a glue or adhesive?

Epoxy is a thermosetting plastic material that acts as a powerful adhesive, forming a strong bond when cured, and is available in both liquid and resin forms.

When should you not use epoxy?

Epoxy should be avoided in unsuitable climates for curing, poorly ventilated workspaces, areas exposed to high heat, or surfaces intended for food preparation.

What is epoxy and is it toxic?

Epoxy can be toxic if its chemicals come into contact with skin or are inhaled, potentially causing irritation, allergies, or asthma, so proper safety precautions are necessary during use.

Cure your epoxy resins faster and easier than ever before with Powerblanket.