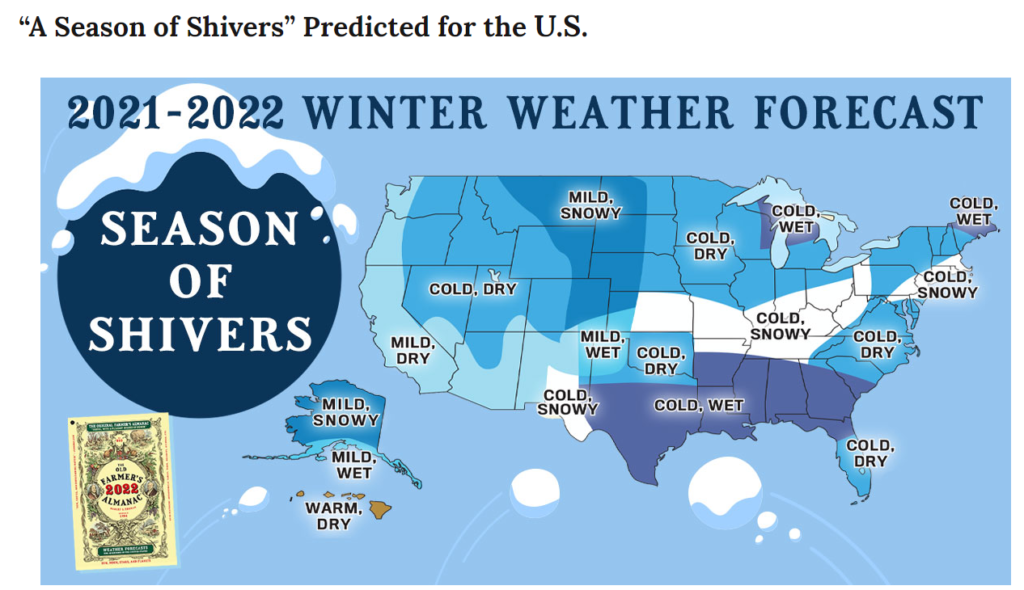

As winter sets in for 2022, we wonder if we are in for another cold one. The Old Farmer’s almanac says we can expect “below average temperatures” across most of the US:

Hard to argue with 230 years and 80 percent accuracy.

Bloomberg and countless other sources relay the assurance that ERCOT has inspected some 302 power plants, about 85% of them, and can assure that they have taken measures acceptable to ERCOT, and deem them ready to go.

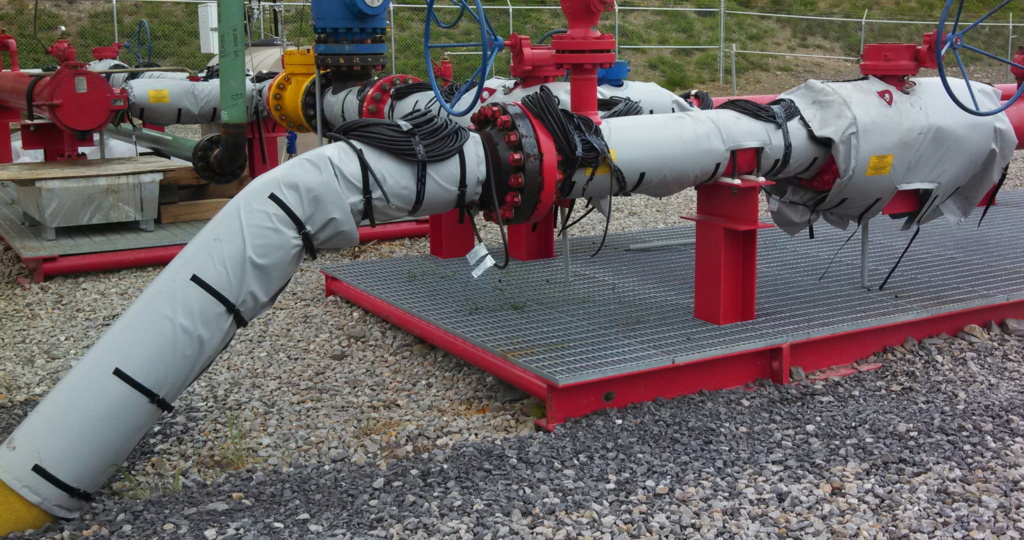

For as long as power plants have been creating power, and midstream companies have been sending natural gas to power plants, freeze ups have been an issue.

This year, more plants than ever are taking advice that has been issued for decades with regard to winter preparation, and in this article we would like to show you how that could be very dangerous to not only keeping the plants online, but to human safety.

One of the most common recommendations for both power plants and midstream companies is to build tarps around critical valves, pumps or other systems that cannot be insulated or heat traced.

End users tasked with heating these enclosures will use several types of heaters to accomplish this task- a few common samples are below

Kerosene or Multi Fuel Heaters

Portable Lamp and Milk House Heaters

While these heaters all will create heat, there are several key issues with using them:

BTU Ratings and R Values– these heaters are not designed to heat an enclosed temporary hooch. You need to know how much heat is required to do the job. Also, the walls are not insulated, no R value has been considered. The enclosure will not be well insulated- tarps are not designed to do that.

Nearly every area covered by a tarp or temporary wall is classified as Class 1 Division 2. The NFPA (National Fire Protection Assoc) Section 70, NEC Code, is “the benchmark for safe electrical design, installation and inspection to protect people and property from electrical hazards”

Power Plants and Gas Plants handle, process and move natural gas. Natural gas falls under Class 1 Division 2 groups B and C normally.

The United States Department of Labor has a little division called the Occupational Safety and Health Administration (OSHA) , and per OSHA Standard 1926.407 , devices and wiring practices within an area considered or rated as hazardous must be rated for that area classification. Bullet heaters, kerosene heaters, milkhouse heaters and heated lamps are not certified to be used in that area.

Imagine a failed pipe, gasket, valve seal or other leak type occurring inside of this temporary enclosure and then imagine this leak running into an open flame or red hot resistor from one of these heaters.

Nearly every location in a power plant or natural gas processing facility has flammable gasses or liquids close by. Nearly every area covered in a tarp is rated Class 1 Division 2. These heaters are not rated for that duty. It is a violation of code to install them inside of a haz rated area. When a glowing resistor or open flame hits a flammable gas or liquid- boom.

Boom, not good.

Taking a commercial heater and plugging it into a commercial outlet within a temporary enclosure like this:

Is a violation of the above stated OSHA, NEC and NFPA standards when doing so within a hazardous area. Proper power termination must be done.

There are actually legal heaters and cord termination devices that can be used. Both the heating device and the termination method must be legally certified by the NFPA, CSA, UL, ETL or another legally authorized organization that has tested and certified the heater for a hazardous area classification.

Powerblanket offers a new and unique solution for many of these key components and a way for most plants to eliminate these heated enclosures.

Non heat traced components can now effectively be protected thanks to products recently developed by Powerblanket. Valves, Transmitters, Pumps, Small tanks all can be individually covered and protected while meeting Class 1 Division 2 requirements.

There is no longer any need to build ineffective and dangerous tarps around critical non heat traced components. Recently developed product offerings for heating valves, transmitters, pumps, pipes and many other components offer solutions to these problems that have never been offered before. Enclosures can even be safely surrounded by Class 1 Division 2 insulated walls by Powerblanket- and still leave plenty of room for maintenance personnel to access the enclosure

Powerblanket Hot Boxes integrate heat and Class 1 Division 2 rated safety- and can be made to fit a wide variety of sizes:

Powerblanket Valve and transmitter Boxes can fit right over key valves and actuator systems to keep that valve control performing throughout that cold winter snap:

Dozens of other possible sizes and configurations can be created exactly for your application.

120-208 or 240Vac and up to 180 F Maintain Temperature. We have heated frac tanks and we’ve heated components the size of your pinky.

Powerblankets are 100% made in the USA in Salt Lake City, Utah. 100% customizable and can be rated for use in Class 1 Division 2 areas. Safe, effective and fit to your application.

Curious to see how Powerblanket can meet the unique needs of your industry?