When working in a Class 1 Division 2 hazardous location, the idea of a heating element usually brings more concern than comfort. That’s why Powerblanket produces products that are Class 1 Division 2 certified and entirely safe for the industries we serve.

Class 1 Division 2 and You

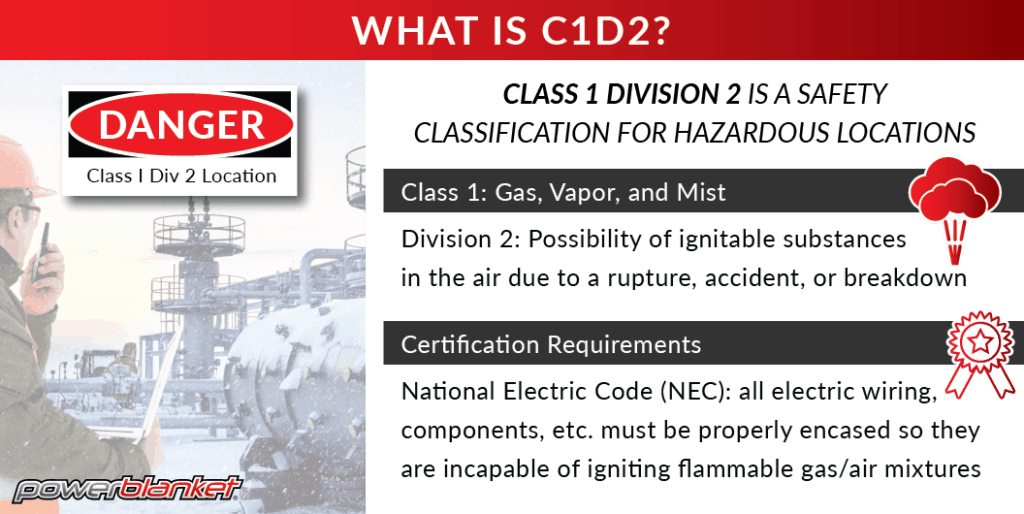

If the title of this article caught your interest, perhaps it’s because you already know a thing or two about Class 1 Division 2 certification, or maybe it’s a new term to you. Either way, here follows a general breakdown:

Class Codes

Hazardous locations are defined by the risks that are present. Some of the most common risks to property and person account for damage or injury through fire, explosion, electrocution, and other similar causes. Based on stipulations outlined by the NEC (standing for National Electrical Code) hazardous locations are defined by certain categories, or classes, and divisions.

Class 1

Class 1 (also known as Class I, with Roman-numeral 1) is made up of risks posed by flammable gases, vapors, and liquids.

Class 2

Class 2 is combustible dust. This is especially dangerous when operating in an enclosed environment, such as a coal mine or a wheat processing facility.

Class 3

Class 3 accounts for ignitable fibers and flyings. These are fabrics and shavings that can catch fire when exposed to sparks or flame.

In the case of a Class 1 Division 2 environment, we’re talking gases, vapors, and liquids that could be potentially dangerous. How dangerous is answered by the division with which the area is coded.

Division Codes

There are two divisions that define a classification under the NEC. If an area is classed under Division 1 (they use Arabic numerals on this part) it means that the materials onsite are normally explosive and hazardous. Conversely, if an area is classed under Division 2, it means that the materials present are not in a flammable or explosive form in most cases but that they could become flammable or explosive by accident.

Combining the class and division in CID2 means that the area has gases, vapors, or liquids present that could become flammable gases or explosive by accident but are not under normal circumstances.

Where Did Codes Come From?

The Class and Division codes originated with the National Electronic Code that originated in 1896, 17 years after the invention of the incandescent lightbulb. 23 men gathered together in New York City at the American Society of Mechanical Engineers to create the first national electrical code. This uniform effort to create a standard of rules that regulate electrical work was a huge step in the direction of safety and efficiency.

According to the National Fire Protection Association, there were many hazards when working with electricity in the early days of electrical power.

“The electrical industry was in its infancy, but growing rapidly. Questions were arising about the safety of electricity. In the electrified mills of New England, electrical fires were becoming commonplace. The Associated Factory Mutual Fire Insurance Companies reported 23 fires in 65 insured textile mills in New England. Frequent electrical fires at the Palace of Electricity at Chicago’s 1893 World’s Columbian Exposition caused many to wonder if electricity could be used safely.”

The new rules written by the group, all representatives of various industrial organizations, were a result of several other failed attempts to set guidelines for electrical safety. This was the first truly universal code to be adopted by businesses across the United States.

“Professor Francis B. Crocker of Columbia University a member of the American Institute of Electrical Engineers (now IEEE) is credited with organizing the first meeting. The Group elected a chair from the National Electric Light Association (EEI) Mr. William J. Hammer and a Secretary from Factory Mutual, Mr. C.J.H. Woodbury, who was representing the American Bell Telephone Company during the meeting. Each of the representatives was invited because they came from an organization that was national in scope.”

Throughout the 20th Century, fire codes and other industrial safety codes were established for the purpose standardizing safety practices in every environment. Chemical hazard classifications, as described earlier, were also made a part of these codes.

The National Fire Protection Administration, which administers the National Electric Code, continually gathers information and input for the purpose of updating the code. Every three years, the code is revised and republished to ensure that new technologies and energy transfer methods are incorporated.

Today, these codes are completely adhered to by all industrial professionals in every field. Contractors, inspectors, laborers, etc. are all held to the same standards of safety that prevent disasters and loss of life and property.

Powerblanket and the Industries We Serve

Powerblanket serves the freeze-protection and heating needs of many industries—such as the construction, chemicals, wax, oil and gas, railroad, spray foam, wind power, and epoxy industries to name several. Keep in mind that many of the customers we serve have to deal with potentially dangerous situations. Powerblanket designs Class 1 Division 2 (C1D2) certified products meet our customer needs in hazardous location freeze protection.

If you need heating solutions for your industry, even if there are potential hazards involved, Powerblanket is the right choice. We are able to meet nearly job specifications with our standard line of heating blankets. For those jobs that require extreme care and highly unique requirements, our custom designers can create the exact product you’re looking for.

When dealing with sensitive materials in a CID2 environment, Powerblanket heating blankets are uniquely suited for use in areas where this is necessary. Give our dedicated team of heating experts a call today with your questions at 855.647.8978, or contact us by email at [email protected].

Frequently Asked Questions

What is a C1D2 area?

A C1D2 area, or Class 1 Division 2, is a hazardous location defined by the National Electrical Code (NEC) where flammable gases or vapors may be present in the air in quantities sufficient to produce explosive or ignitable mixtures under abnormal conditions.

Does Class 1 Div 2 mean explosion proof?

Class 1 Division 2 (C1D2) does not necessarily mean explosion-proof; it indicates that explosive atmospheres are less likely to be present but may still occur under abnormal conditions, requiring equipment that can safely operate in such environments.

What is the difference between C1D1 and C1D2?

C1D1 represents areas where hazardous gases are present during normal working conditions, while C1D2 signifies that such gases are present only under abnormal circumstances.

What is a Class 1 Div 2 enclosure?

A Class 1 Division 2 enclosure is used in facilities handling flammable gases, vapors, and liquids, ensuring that any concentrations present are insufficient to ignite under normal conditions.

Keep your equipment running smoothly and prevent damage with Powerblanket's advanced hazardous location heating systems.