How Should Chemicals be Stored?

If you work with chemicals, you’re probably well aware of the hazards associated with their use. You’re likely familiar with how to safely work with chemicals, but how should chemicals be stored? Chemical storage is an important part of safe chemical handling. Knowing how to store chemicals safely will help protect the environment and employees who work in areas where chemicals are contained and used.

Safe Chemical Storage Begins With Building Safety

Prevent serious location damage. The following are some guidelines to help protect against fires, fumes, and other risk associated with chemical storage:

- Construct and furnish buildings with non-combustible materials.

- Avoid flood zones.

- Allow only authorized personnel into chemical storage facilities.

- Install and regularly check fire and smoke detectors.

- Ensure your building has enough exits and clear escape routes in case of a fire or other disaster.

- It should be easy for any emergency responders to access the building in case of an emergency.

- Make sure the building is properly ventilated to prevent the build up of hazardous fumes.

- Provide proper lighting in your building so all chemical labels can be clearly read.

- Have adequate air conditioning and/or heating to prevent any temperature extremes that could damage containers or product and lead to leaks or fires. A manufacturer’s SDS (safety data sheet) shows correct storage temperatures for each chemical.

- Make sure your building provides enough space for safe chemical storage. Designated an area for chemical storage and transfer. Separate this area from any other work areas.

Protecting Against Leaks and Spills

Knowing how to prevent leaks and spills and how to properly deal with them can prevent more serious accidents from occurring.

- Have proper absorbents on hand in case of spills or leaks.

- Place drip pans under drum faucets and any leaks.

- Securely install shelves and do not exceed the maximum load on any storage racks or shelves.

- Have larger containers available to contain damaged or leaking chemical packaging. Make sure your secondary storage has equal or greater structural integrity than the stored package. Dispose of or repackage damaged packages.

Proper Storage of Hazardous Materials Prevents Accidents

- Store and sort non-hazardous chemicals alphabetically on shelves or in cabinets with secondary containment (a chemically compatible tray, usually plastic) provided for liquids and oxidizers (dry and liquid).

- Hazardous chemicals must be separated by compatibility groups before storing alphabetically.

- Always store hazardous chemicals below eye level to reduce accidental splashes to the eyes and face.

- Store liquids and oxidizers (dry and liquid) in secondary containment. This is especially important when storing incompatible chemicals in the same acid cabinet or flammable materials cabinet.

- If storing chemicals on a shelf, instead of a cabinet, make sure the shelf has a 1″ high lip to prevent the containers from falling.

- Fume hoods and laboratory benches are not acceptable storage areas for chemicals, and these areas should be maintained in an organized fashion, free of clutter. Only working quantities of chemicals should be kept in chemical fume hoods.

- Use a cart with sides when moving chemicals and use a secondary containment tray to separate chemicals in case of spills.

Labeling Hazardous Chemical Containers

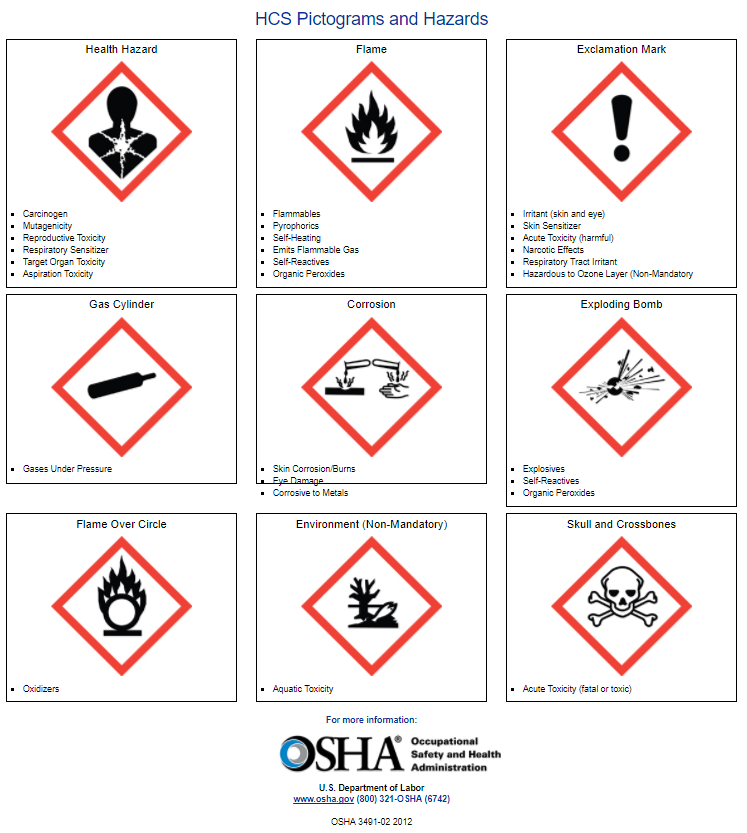

It’s crucial that personnel who handle or work near chemicals be familiar with the risks they pose. All chemical containers should clearly indicate any hazards with appropriate safety signs.

https://www.osha.gov/Publications/HazComm_QuickCard_Pictogram.html

- During storage, label all chemical containers with the Identity of the Chemical(s) therein and Appropriate Hazards Warnings, in words, pictures, symbols, or a combination thereof (as shown above) which provide all of the hazard information. Labels on containers with mixtures of difference chemicals must indicate the constituents and approximate percentages of each.

- Containers of Waste Chemicals must have a completed label. Use this label for unwanted chemicals that are not “chemical waste” items.

- To assist Emergency Responders, label door(s) to all rooms and laboratories where hazardous materials are stored.

Self-Inspection

In addition to proper labeling, inspect storage areas monthly.

Compressed Gas

- Secure gas cylinders to a stationary object with a chain or strap two thirds of the way up the cylinder to prevent falling or tipping. Best practice is to secure them individually. In some cases it may be acceptable to secure small groups of cylinders together.

- Do not store cylinders of liquid nitrogen in areas that do not have ventilation, such as cold rooms.

Flammable and Combustible Materials

The Management of Flammable and Combustible Materials is critically important to ensure that these materials are properly used, stored, and disposed of.

Never store flammable and combustible materials in a household refrigerator or freezer. Use only a unit approved for storage of flammable material, commonly called “intrinsically safe” or “flammables storage” refrigerator/freezer. An “explosion proof” unit is not necessary only for flammable materials.

Chemical Compatibility

Proper segregation of incompatible chemicals is critically important to preventing chemical interactions.

This Hazardous Chemicals of Concern List and Storage Guide from Marshall University provides information about chemicals commonly found in labs and divides them into compatibility groups. Store the chemicals in each of the 10 groups away from the other groups. Do not store incompatible chemicals together; however, incompatible chemicals may be stored in the same cabinet if secondary containment is provided.

Store unwanted chemicals according to chemical compatibility, and only in chemically compatible containers. Cole-Parmer maintains a searchable database for determining container compatibility.

Date peroxide-forming chemicals when received because of their additional hazards. Tested these chemicals for the presence of peroxides and the results of testing recorded on the label. Dispose these chemicals promptly if levels exceed 25 ppm.

Chemical Temperature Control

As mentioned above, storing at proper temperatures is an important part of chemical safety. Correct temperatures will help prevent fires and container damage and leaks. Additionally, proper temperatures help chemicals perform correctly. Chemical Heating Systems provide temperature control for chemical storage without creating hot spots. They can be used in a wide range of environments and are UL/CSA certified. If you’re looking to increase the safety and efficiency of your chemical storage, Powerblanket products might be just what you need!

Powerblanket's industrial drum & barrel heaters provide even and consistent heating, eliminating waste and lowering costs.