“Build a better mousetrap, and the world will beat a path to your door.” Poet Ralph Waldo Emerson made that quote in the mid-1800s when wooden barrels were the primary storage system. But what about building a better storage container?

Wooden barrels have been around for over two thousand years. However, they have limitations on the types of materials they can hold. Their most significant drawback is the difficulty in handling. With modern palletization and containerization, there is something better. It’s the IBC or Intermediate Bulk Container. Olivier J. L. D’Hollander invented the first IBC tote for Dow Corning S.A. in 1992 and revolutionized the shipping industry.

But even the tough IBC needs some additional protection. This post will highlight the various tote covers and provide insights to help you find the right solution for protecting sensitive cargo.

What are IBC Tote Covers?

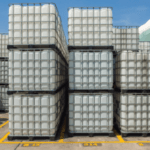

Before we talk about the IBC tote covers, let’s talk about the totes. Intermediate Bulk Containers (IBC) are almost square, like building blocks. The dimensions for a 275-gallon tote are 48 x 40 x 42 inches tall, and for the 330-gallon model, they are 42 x 48 x 47 inches tall. They hold more product than 55-gallon drums, are stackable and are easier to handle for intermodal transportation.

A tote is a synthetic tank surrounded by a metal cage, usually stainless steel, for durability and handling. Sometimes the materials inside the totes must be protected from light or adverse temperatures. That’s where IBC tote covers come into the picture. Covers slip over the top, surrounding the tote from top to bottom to protect from the elements.

Types of IBC Tote Covers

Tote covers protect the tote and its contents from the elements. Depending on the product, there are several choices of materials.

Oxford Cloth

Oxford cloth is a shiny, lightweight nylon fabric. It is durable yet weighs only 170 grams per square meter. We find this tough material in backpacks, tents, and sail covers on sailboats.

It comes in different densities such as 210d, 300d, 420d, and 600d. The higher the number, the thicker the threads and denser the material. “D” is an abbreviation for Denier, a unit of thread density or yarn.

Woven Polypropylene

Also called “PP,” this rugged, high-strength plastic fabric is weatherproof. It is mildew, insect, tear, and chemical resistant. However, it is typically white and does not filter out light or UV rays.

Plastic

For tote covers, plastic film is not a good choice except for a temporary dust cover for the top of the tote. It’s not very durable for transporting or long-term storage.

Vinyl

Vinyl is an excellent material for tote covers. It blocks out sunlight, UV rays, and it’s waterproof.

For example, people worldwide are modifying totes to collect rainwater as a water source. The problem arises when too much sunshine causes an algae bloom.

How To Keep Algae from Growing in IBC Totes?

There are homegrown methods to block the sun by painting the totes. Unfortunately, paint that adheres to plastic is expensive and does not block UV rays. It also requires disassembling the tote.

Another DIY method is to remove the tote from its cage and wrap it in black plastic using duct tape. Although this will work temporarily, duct tape is not weatherproof and will deteriorate, leaving the ugly, loose-plastic flapping in the breeze.

The best solution to preventing algae is an IBC tank cover specifically designed to fit over the tote, which offers complete light and UV protection.

Powerblanket IBC Tote Covers Protect Two Ways

Most tote contents need protection from light and freezing temperatures.

Like any plant, algae need light to grow. Powerblanket IBC tote covers provide total light and UV protection, prohibiting algae growth inside the totes. But that’s only one way they protect the contents.

Many products are temperature sensitive, especially at the freezing point of water. Temperature control inside IBC totes can be challenging to manage, but it is essential to maintain a consistent temperature to preserve product integrity. One way to accomplish this is with a heating blanket or heated tote cover to regulate the temperature of the contents.

Powerblanket offers IBC heater solutions suitable for outdoor use. They come in either 120v or 240v models that transform into tote heaters during the cold months. Heat is essential to maintaining a steady viscosity on a broad range of liquid products, making them easier to dispense and reducing waste.

Heated IBC tote covers can increase temperature-sensitive materials safely up to 145°F (63°C). The patented design evenly distributes the temperature throughout the container. For totes stored in frigid temperatures of -20°F (-29°C), Powerblanket’s Xtreme line of tote heaters protects sensitive contents in severe climates.

These heavy-duty IBC container covers fasten securely around any standard tote, from 250 and 275-gallon tote covers, up to 330, 350, 450, and 550-gallon sizes. They have a weather-resistant vinyl shell with insulation and heating ribbons inside.

IBC tote covers are waterproof. They slide over the top and sides then cinches closed using reinforced straps for a weather-tight fit. For more information and specifications, click on Powerblanket IBC heating solutions.

Frequently Asked Questions

Should I cover my IBC tote?

Yes, covering your IBC tote is essential to prevent algae growth by blocking sunlight and to protect the contents from adverse weather conditions.

How do I protect my IBC tote from the sun?

To protect your IBC tote from the sun, use a UV-resistant cover that fits over the container, providing a barrier against UV radiation, dust, and moisture.

What is the lifespan of an IBC tote?

Under ideal conditions, IBC totes can last for 5 years or longer, depending on usage and environmental factors.

Keep your temperature-sensitive materials at the right temperature with Powerblanket IBC tote warmers and heaters.