For anyone with experience in gas pipelines, hydrate formation is no new phenomenon. But even if you work or have worked in the natural gas industry, it’s worth revisiting the cause behind hydrate formation and how it can be prevented altogether.

What Are Hydrates?

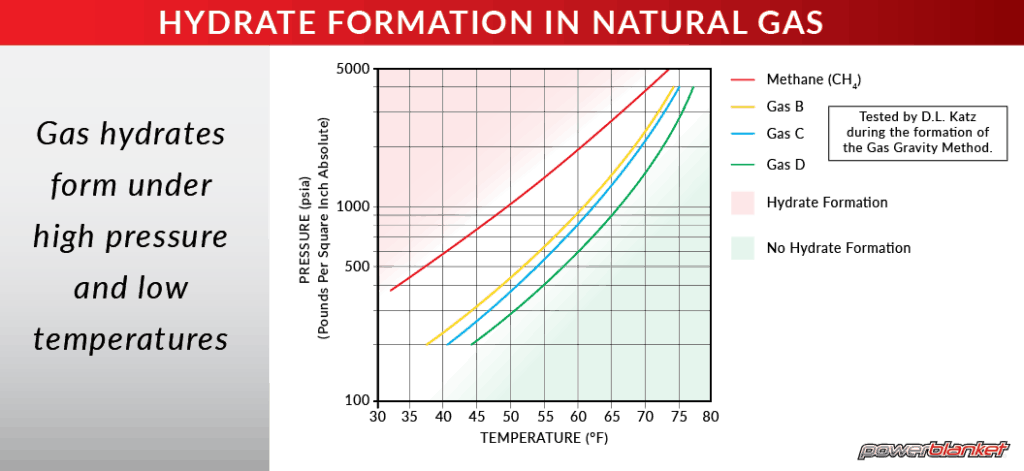

The term hydrates may sound relatively harmless, but when it comes to gas pipelines, harmless certainly isn’t the case. Hydrates are solid, crystalline compounds that form when water molecules chemically bond to another compound such as carbon dioxide or other hydrocarbons. Gas hydrates typically form under high pressure and low temperatures—in this case, natural gases of any form.

Hydrate History

During the start of the 20th century, the natural gas industry began to have troubles with pipeline blockage. The blockages appeared to look like ice. In 1934, E.G. Hammerschmidt made the discovery that these ice blocks were actually gas hydrates. Not long after this discovery, in the 1940’s, Professor D.L. Katz and his students at the University of Michigan, conducted a study that nailed down exactly when these hydrates form. Their study laid out what it known as the gas gravity method.

The Gas Gravity Method

Katz and his students exposed 4 different groups of gases to different temperatures and pressures to find out the exact conditions needed for hydrate formation. 3 of the gas groups were mixtures of different gases, and the 4th was pure methane (CH4). Their charted findings clearly illustrate that gas hydrates form when gasses are subjected to high pressures and low temperatures.

The Negative Effects of Hydrates

Hydrates are certainly the enemy for any pipeline transporting gas under high pressure. In addition, this problem becomes compounded as temperatures drop close to and below freezing.

With that said, the formation of hydrates can and will occur in temperatures above freezing too. So regardless of where the pipeline runs, hydrate maintenance is something to keep high on the priority list.

Flow Blockage

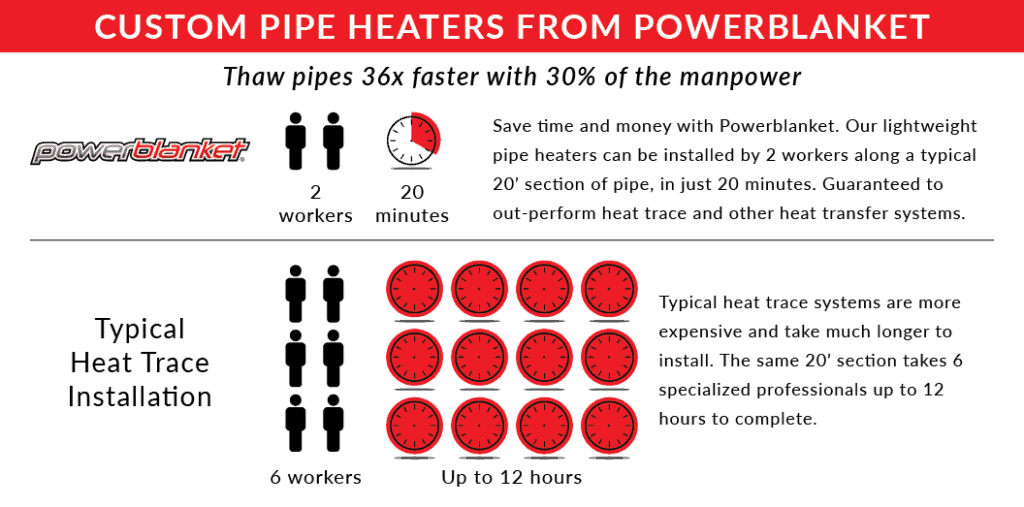

Ultimately, hydrates can drastically impede and even stop the flow of gas through a pipeline. This occurs especially around transition points such as valves, manifolds, and instrumentation. These transition points are where the problem is often encountered. Heat trace applications can sometimes be used to keep temperatures high enough to prevent the formation of hydrates in long sections of pipe. However, applying heat trace to the aforementioned transition areas is time consuming and expensive.

You don’t need traditional heat trace methods to prevent hydrate accumulation. No, there’s a much simpler solution to the problem. A pipeline needs something that can be easily installed and removed, something that provides heat and insulation in one simple, easy-to-use system. Thankfully, the ideal solution is right here at Powerblanket.

Powerblanket Pipeline Solutions

To prevent hydrate formation in pipes, valves, manifolds, and instrumentation, Powerblanket has products designed with this specific task in mind. Our custom pipe heater blankets are tailor made to fit exactly around your valves, manifolds, and instrumentation. In addition, these heaters provide durable insulation and evenly distributes consistent heat. We can keep your instruments operating in ideal temperatures ranges, warding off the formation of hydrates completely. What’s more, Powerblanket heaters are easy to install and remove when necessary. Don’t waste energy and money heat tracing your piping system. With Powerblanket, you have the complete solution in one system.

In the world of gas pipelines, equipment is expensive, product is valuable, and time is money. A company’s assets can range from a heavy-duty pipeline down to the products and equipment it uses to service it. So, whatever the case may be, Powerblanket can help you protect your assets against the threat of failure or malfunction.

POWERBLANKET PIPE HEATER BENEFITS

- Maximum freeze protection to -40°F / -40°C

- Engineered to maintain flow

- Reduce downtime and increase profitability

- Easy to install, uninstall, and reinstall

- Rapid thawing for frozen or gelled pipes

- Certified to UL/CSA safety standards

Contact us today to find the perfect custom pipe heating solution for your needs at 866.945.4203 or [email protected].

Frequently Asked Questions

What are the methods of gas hydrate production?

Gas hydrate production methods include depressurization, CH4-CO2 replacement, chemical injection, and thermal injection, which are used in both conventional and unconventional oil and gas reservoirs.

How to prevent gas hydrates?

Gas hydrates can be prevented by removing water from the system, raising the system temperature above equilibrium, decreasing the system pressure below equilibrium, or introducing an inhibitor.

At what temperature and pressure is a gas hydrate formed?

Gas hydrates form when water and low-molecular weight gases like methane combine at high pressures (3 to 30 MPa) and low temperatures (below 25°C).

What are the three types of hydrate formation?

Hydrates are classified into three types based on their crystal structure: Type I, Type II, and Type H, determined by the size of the hydrate former molecule.

Powerblanket's equipment boxes keep your valves and manifolds from freezing in even the harshest outdoor environments.