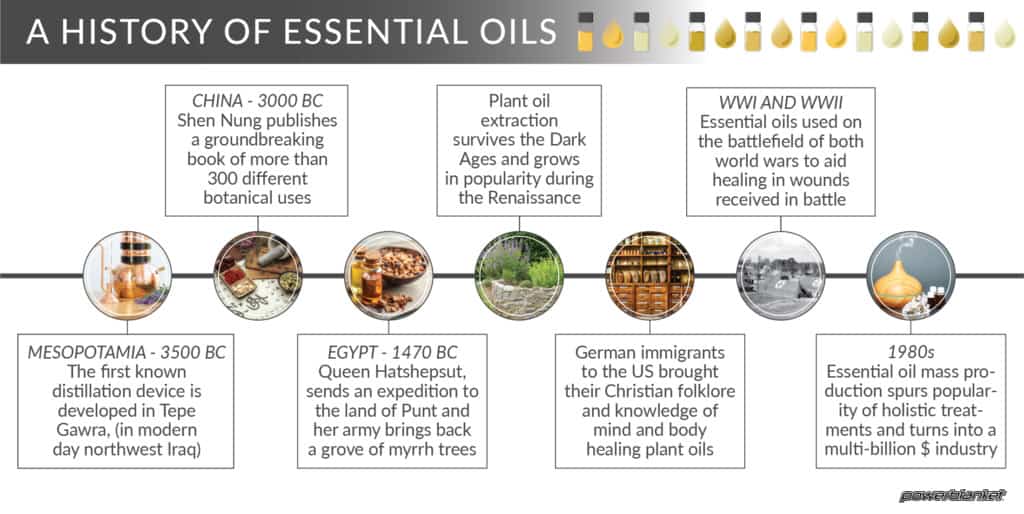

One of the oldest medicinal technologies still in use today is essential oil extraction. The process of removing oils from plants started thousands of years ago…likely when an early human squished an olive in their fist.

Essential Oils: A History

The ancient people of Mesopotamia won the award for the first civilization to record the use of essential oils. The practice of extracting oils from plants evolved as it was picked up by the Egyptians and the Chinese mainly for aromatherapy. According to Utah-based essential oil manufacturer Young Living, Greek explorers brought oil extraction to Europe from Egypt. The practice of medicinally using herbs and oils eventually spread through many cultures around the world.

Plant oil extraction survived the Dark Ages, and grew in popularity throughout the Renaissance. Early German immigrants to the United States in the 18th and 19th centuries brought their Christian folklore with them, which included their knowledge of herbs and oils used in healing the mind and body.

Medical needs in both World Wars helped establish essential oils as a truly pharmaceutical resource for healing battle wounds. However, the mass production of extracting essential oils didn’t really take off until the 1980’s. Consumers began looking for more holistic treatments for diseases and injuries via aromatherapy. Since then, manufacturing plant-based essential oils has become a multi-billion dollar industry.

Essential Oil Extraction

According to doTERRA, another Utah essential oil manufacturer, distilling is the best process to extract essential oils.

“Essential oils are produced by plants naturally and collected by different processes including, hydro-distillation, steam distillation, cold pressing and others. A very common method of extracting essential oils is a low-heat steam distillation process. In this process, pressurized steam is circulated through plant material. The steam carries the volatile aromatic compounds from the plant into a collecting tube, where the steam is cooled and condensed back into water. Because essential oils are lipid soluble, they are easily separated from the water. Steam distillation requires careful control of time, temperature and pressure, based on each plant. Too little heat or pressure and the oil will not release: too much, and the oil’s composition and potency will be affected.”

Each specific oil has its own set of extraction processes. In general, mass produced extraction happens when heat is added to coax oil out of seeds, producing more oil than any other form of extraction. Smaller businesses that extract oils often choose another route, however, since using heat during extraction results in darker colors of oils, as well as a “burnt” flavor in edible oils.

Cold press oil extraction doesn’t use heat. Instead, oils extracted from the seed are filtered over and over again through a strainer. This method takes longer and results in lower quantity but much higher oil quality. Cold press extractions create oils that are nearly 100% pure and preserves edible nutrients that burn away with heat extractions.

CBD Oil Extraction

One essential oil that is rapidly increasing in use and popularity is CBD oil. CBD is extracted from hemp in a different way from other essential oils. SC Botanicals, a South Carolina CBD oil manufacturer, uses a method called supercritical CO2 extraction to ensure the highest quality product.

“Supercritical CO2 extraction in our opinion is cleaner but it’s much more expensive. At the end of the day – as long as each facility and extraction manager is ensuring proper protocols – patients and customers will get high quality products.”

In this method, CO2 is added to extracted crude oils from cannabis plants. The release of the CO2 into the air takes impurities and unwanted chemicals such as THC with it, resulting in virtually pure CBD oil.

Extraction Byproducts

Cold extraction also produces byproducts that can be sold in addition to the essential oils. Pressed plants that have had their oil extracted are often sold as “cake” to other industries. For example, the agricultural industry uses pressed plant cake as a common ingredient in animal feed. Some oil manufacturers separate lavender oil from lavender water in large vats. After the water is drained it is sold to other companies for further use.

Powerblanket Essential Oil Solutions

In all methods of plant oil extraction, temperature control plays a critical role. Essential oils should never be stored at temperatures above 80°F or below 45°F. That’s why Powerblanket provides heating control solutions in the form of warming blankets that keep essential oils at the right temperatures during extraction and in storage. When combined with the Beacon smart controllers, you have full access to temperature adjustments and heating data monitoring from your mobile device or laptop.

For more information, call Powerblanket’s essential oil product experts at 855.389.4792 or by email at [email protected].

Frequently Asked Questions

How do you extract oil from plants at home?

To extract oil from plants at home, you can use methods like steam distillation or cold pressing, which involve circulating steam through plant material or filtering oil from seeds without heat, respectively, to preserve the oil's purity and nutrients.

How do you extract oil from fresh herbs?

To extract oil from fresh herbs, you can use a simple infusion method by covering the herbs with a carrier oil, allowing the mixture to sit for a couple of weeks, and then straining it to separate the oil.

What are the methods of oil extraction?

The primary methods of oil extraction include steam distillation, cold pressing, and solvent extraction, each offering different benefits in terms of yield and oil quality

How to extract vegetable oil from plants?

Vegetable oil can be extracted from plants by pressing the seeds or nuts to release the oil, often followed by solvent extraction for a more complete yield.

When you need a custom temperature control solution, Powerblanket is the company to call. With over 30 years of experience, we can solve any heating dilemma you have.