An Atypical Concrete Job

Concrete curing in freezers is a unique experience. Walk in freezer concrete floor construction requires a specially cured solution that can handle constant sub-freezing temperatures. This concrete is also required to be strong enough to support heavy equipment traffic from forklifts and other machinery. These freezers are a crucial part of the cold chain that protects the safety of cold products (such as meat, ice cream, medicine, cadavers, liquid oxygen, and more) during transport and storage. Walk in freezer failure is an expensive, and dangerous broken link in that refrigeration cold chain. When the structural integrity of a walk in freezer is jeopardized, the contents within can spoil, creating a huge employee and consumer safety hazard. Not all walk in freezer failures are preventable. However taking a few extra precautions during concrete curing in freezers can prevent costly downtime and repairs.

Prepare The Ground

There are a number of layers that need to be in place before pouring to protect your concrete from freezer floor heave. Freezer floor heave occurs when the moisture in the soil freezes and expands below your slab. If the soil then begins to thaw, it will also sink and settle, causing massive damage to the concrete above. Protective layers of insulation, vapor barriers, mud-slabs, and sub-slab glycol heating prevent the soil from freezing and swelling below your concrete floor.

Maintain The Mix

Ensure your mix of concrete doesn’t contain too much water. An overly wet mix is likely to cause cracking due to shrinkage. The water can also freeze within the concrete if it’s not cured enough by the time the freezer begins operating. Your concrete freezer floor may appear set on the surface, but the lower layers will not be strong enough to bear weight or thermal stress.

Ensure The Cure

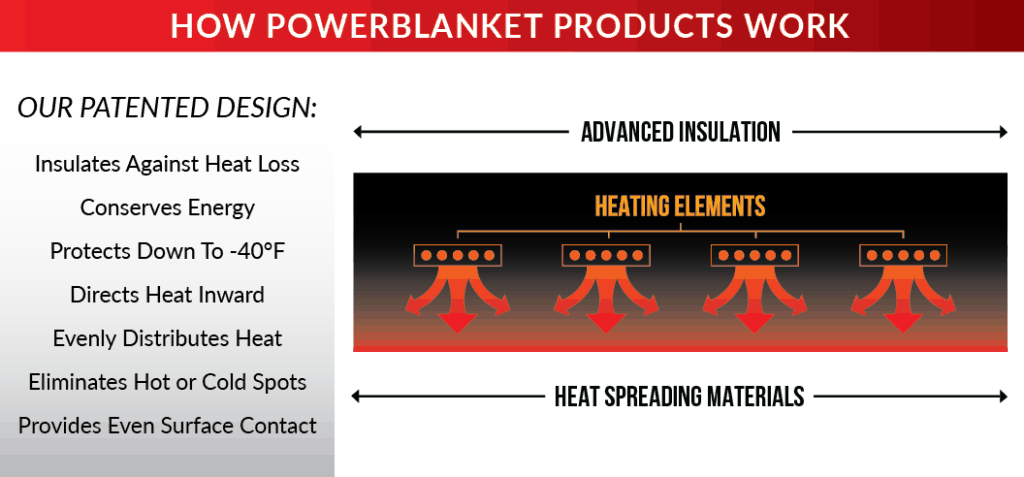

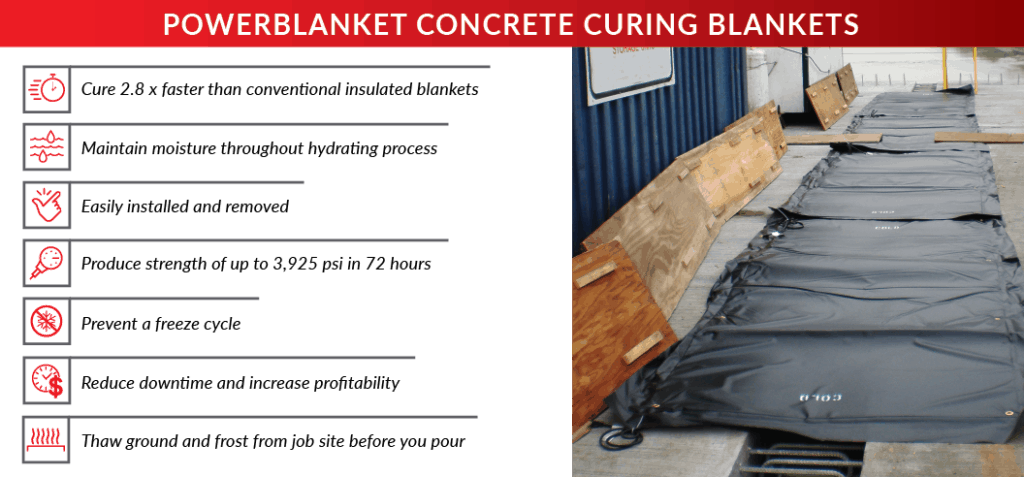

Walk in freezer floors need to endure constant walking foot traffic, heavy stacks of pallets, and forklifts. Your concrete needs all the compressive strength it can get to withstand such thermal and physical stress. Using concrete heating blankets, instead of traditional insulated blankets, ensures your concrete floor cures faster and to a stronger PSI rating.

Seal The Deal

The United States Dairy Association (USDA) has a zero-tolerance policy regarding leaks within a freezer. Frozen food requires storage at 0°F, as “freezing to 0° F inactivates any microbes — bacteria, yeasts and molds — present in food.” Leaks allow moisture to invade the freezer, which can trigger mold and other harmful pathogen growth. Properly sealing concrete floors in a walk in freezer protects your slab, prevents leaks, and maintains USDA safety compliance requirements.

As a leader in concrete heating solutions, Powerblanket offers the most advanced and reliable concrete curing equipment. These cutting-edge curing blankets not only accelerate concrete curing time but also increase concrete strength and quality. Investing in Powerblanket solutions will ensure your concrete pours meet the required specifications every time.

Restoring Concrete Freezer Floors

Concrete floor damage, like cracking or chipping, is triggered by a number of factors such as: forklift accidents, threshold damage, sub-floor heating replacements, and freezer floor heave. Our friends at Concrete Mender warn of several concrete repairing challenges:

Frost

Frozen moisture in the concrete will act as a barrier between the repair material and the pores of the concrete. Most repair materials will try to bond to the frost coated concrete. When the temperature increases, the frost melts and so does the bond.

Ambient Temperatures

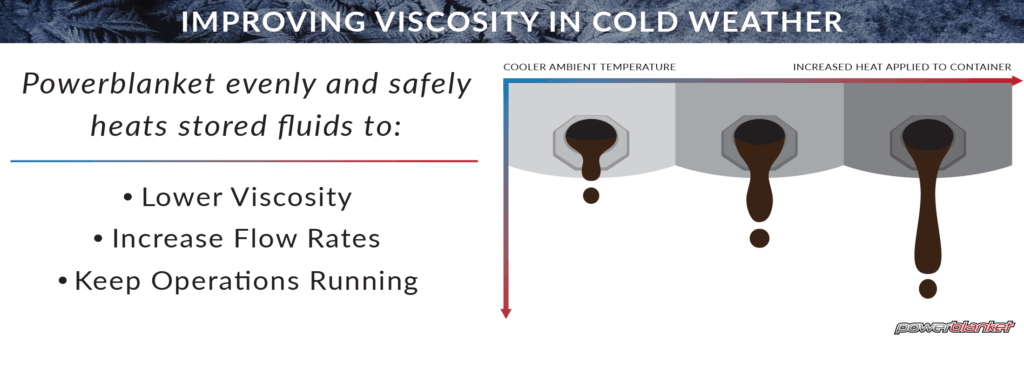

Mixing epoxies or mortars in the cold is especially challenging. As the temperature decreases, the viscosity of these materials increase making them very difficult to pour, mix and work with. Bucket and drum heaters are an excellent solution to keeping epoxy and mortar warm while waiting to use on a freezer floor.

Curing

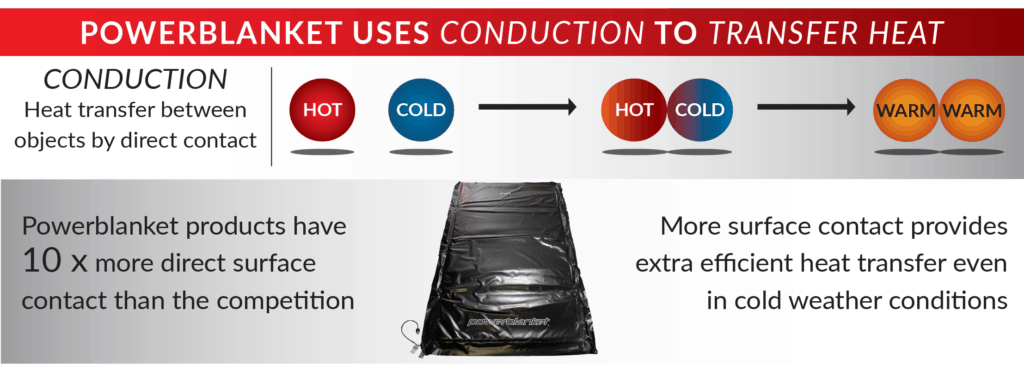

Materials used to patch and repair concrete cure much more slowly at cold temperatures. A product that takes 1 hour to cure at room temperature can take 12 hours to cure in cold temperatures. Some materials may actually freeze solid before they can cure properly. Keeping patching materials warm during the curing process will cut down your cure time and increase their durability. Curing blankets are the most efficient way to ensure your repairs cure quickly and firmly. Curing blankets heat through conduction and have complete surface contact to transfer heat directly where it is needed most.

Concrete Solutions From Powerblanket

There are a lot of elements involved in preparing and pouring a concrete freezer floor. When things go wrong, repairing a damaged freezer floor is just as challenging. Taking extra precautions before, during, and after you pour will ensure your slab is built to last.

For everything about concrete curing in freezers, Powerblanket is here to help. With our wide range of bucket and drum heaters, you can keep your materials warm and ready to use for any repair job. Our concrete curing blankets are the perfect solution for quickly achieving high PSI ratings. With a cure rate 2.8 times faster than conventional insulated blankets, you can be sure to meet project deadlines on time. Contact us to find the perfect solution for all of your concrete needs 855.447.9358 or [email protected].

Frequently Asked Questions

Can a walk-in freezer have a concrete floor?

Yes, a walk-in freezer can have a concrete floor, which is durable enough to withstand heavy traffic and product weight, but it should be properly insulated and sealed to enhance energy efficiency and prevent moisture issues.

How do you insulate a concrete floor for a walk-in freezer?

To insulate a concrete floor for a walk-in freezer, use a layered approach starting with a vapor barrier, followed by insulation materials, and then a protective top layer to maintain temperature and reduce moisture.

How thick is the floor in a walk-in freezer?

The floor in a walk-in freezer typically ranges from 4 to 5 inches thick, incorporating insulation and a durable top layer to ensure structural integrity and thermal efficiency.

What are the OSHA regulations for walk-in freezers?

OSHA regulations for walk-in freezers require that exit route doors must be operable from the inside at all times without the need for keys, tools, or special knowledge, ensuring safety and accessibility.

Cure your concrete faster and better in cold weather conditions with Powerblanket.