If you really want to know the truth, concrete never stops curing; it continually hardens forever. However, for practical purposes, it reaches a point where further hardening will be so slow it becomes unnoticeable. In this article, we cover the basics of what you need to know if you’re asking the question, “how long does concrete take to set?”

Concrete Never Stops Curing

The continual hardening occurs because cement particles react with the water in the mix (hydration), and as long as cement is in contact with moisture, even minuscule bubbles, it will continue to form bonds. This is minimal after “full strength” is achieved, but it is continual.

Initial Setting Times for Concrete

In standard industrial cases, full-strength concrete is recognized at 28 days. At seven days, you should have concrete that is cured to 70% full strength or greater. But to answer the question of, “How long does concrete take to set?” concrete setting time is generally 24 to 48 hours. At this point, the neighborhood dog will not leave his footprints in it, but you should keep it clear of heavy equipment during this time period. Most mixes are cured at 28 days.

With so many factors affecting concrete’s setting time, having the right tools is critical. Powerblanket’s Concrete Blankets allow you to control and accelerate concrete curing in any weather conditions.

Factors Affecting Concrete Setting Time

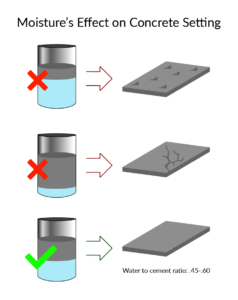

Moisture plays a critical role in curing time for concrete. If there is not sufficient water in the mix, the concrete will cure too fast, resulting in weaker overall strength. Too much moisture, often used in the finishing step will weaken the top layer and cause flaking.

Moisture plays a critical role in curing time for concrete. If there is not sufficient water in the mix, the concrete will cure too fast, resulting in weaker overall strength. Too much moisture, often used in the finishing step will weaken the top layer and cause flaking.- Hot ambient temperatures and wind accelerate the evaporation of moisture–speeding concrete setting time.

- The mix design has a lot to do with concrete setting time. Some jobs will require accelerants because the area needs to be usable as soon as possible. The accelerant will do its job and speed up the concrete setting time. Accelerant mixes will show a weaker overall strength in the end but will still meet strength requirements.

Temperature also has an impact on concrete setting time. For more information, check out this article about how concrete curing temperature makes a difference.

Concrete Blankets

If you are wondering about how long concrete takes to set, a solution for your concrete setting needs is a concrete heating or cooling blanket. But not all blankets are created equal. Consider the following two types of solutions to the effects of hot and cold:

The FluxWrap from North Slope Chillers is portable cooling equipment that will keep newly poured concrete safe from heat, regulating concrete setting time in both regular and hot conditions.

The FluxWrap is combined with either a cooler or chiller to achieve optimum results. The Circulation Blanket draws heat to the blanket in order to cool the concrete.

- Use Powerblanket’s patented heat-spreading technology in reverse–the cooling blanket draws heat away and lowers the temperature of the concrete.

- Take it with you on every job. It is easily portable.

- Blanket cover and insulation are the same as the robust system used in Powerblanket heating products

- Control the curing speed of newly poured concrete even in hot conditions

If conditions are cold, concrete curing blankets provide a manageable way to cure concrete effectively and confidently. Powerblanket curing blankets increase production by rapidly curing with consistent, even heat.

- Cure concrete 2.8 times faster than conventional, insulated blankets

- Maintain moisture throughout hydrating process

- Easily installed and removed

- Produce cold weather concreting strength of up to 3,925 psi in 72 hours

- Prevent a freeze cycle

- Thaw ground and frost from job site before you pour

- Reduce downtime & increase profitability

- Maintain ACI compliance for cold weather concreting

Realize that just because you have a concrete curing blanket doesn’t mean you have a solution. The type of blanket and how that blanket is used will have a massive impact on your concrete. Read more about curing blankets here.

Frequently Asked Questions

How long does it take a 4 inch slab of concrete to cure?

A 4-inch slab of concrete typically reaches its initial set in 24 to 48 hours, can handle light traffic after 7 days, and is fully cured at 28 days.

How long should concrete cure before putting weight on it?

Concrete should cure for at least 7 days before supporting vehicular or construction traffic, although it reaches full strength at 28 days.

Can I walk on concrete after 12 hours?

While it's best to wait 24 hours before walking on new concrete, it takes 28 days to fully cure and support heavy items.

Is it okay if it rains on new concrete?

Rain is generally not a problem once the concrete has set hard enough to walk on, typically 4-8 hours after pouring, as the curing process continues over 28 days.

Cure your concrete faster and better in cold weather conditions with Powerblanket.