One-Piece Flow and Making it Work for You

Glossary of Terms

If you are new to the idea of one piece flow, or looking for a refresher, here are some terms that are good to be familiar with.

- Lean manufacturing or lean production is a systematic method originating in the Japanese manufacturing industry for the minimization of waste within a manufacturing system without sacrificing productivity, which can cause problems. Lean also takes into account waste created through overburden and unevenness in work loads ).

- One Piece Flow (Single-Piece Flow) refers to the concept of moving one workpiece at a time between operations within a workcell.

- Takt time is the average time between the start of production of one unit and the start of production of the next unit, when these production starts are set to match the rate of customer demand.

- Kaizen is a Japanese business philosophy of continuous improvement of working practices, personal efficiency, etc.

Lean Manufacturing

Focused on purpose, process, and respect for people, lean emphasizes creating the best value for the customer, while minimizing resources, time, energy, and effort used. Every lean manufacturing goal is to achieve one piece flow. One-piece flow allows for the most efficient production operations. Thinking of processing one unit at a time can seem quite daunting you don’t operate this way. However, when incorporated properly into your workflow and paired with the right technology to support the process, one-piece flow manufacturing change your processes for the better very quickly. It has taken Powerblanket many years to achieve one piece flow production. To maintain this production process requires overcoming challenges such as maintaining standards, level loaded schedules, continuous training, and waste reduction.

One Piece Flow

One-piece flow is centered around balanced cycle times, takt time requirements, and a level loaded schedule. Takt time is the rate at which a finished product needs to be completed to meet customer demands. We have built our production lines to meet desired takt time calculations and expand production cells to lower takt times if needed. Achieve takt times with balanced cycle times from cell to cell. Cycle times are individual times per production cell that records process time and delay time. Powerblanket has also designed an internal scheduling software system to meet our unique application and processes. Our schedule is driven from takt times and available operators to output total units to be built and time requirements to follow.

Traditionally, like many manufacturing environments, Powerblanket had been producing product using the “batching” process. This process is obsolete here at Powerblanket as we have transitioned to the more beneficial “single-piece flow” process. As this process continually improves, and becomes more efficient, we are able to produce more with less, and expand our production to focus on custom heating solutions vs. our standard products. This allows us to grow our business and offer more options to our customers.

Benefits of One Piece Flow

- Inventory Reduction: Companies can maintain a small volume of safety stock reserved for standard products. Customer demands control volume. This requires each operation to only build product needed by the next operation.

- Ensures a Safer Work Environment: Less inventory means less clutter, which provides opportunity to improve layout of equipment in the work station and the layout of the cells.

- Floor Space Reduction: Each operation is built one piece at a time so removal of WIP (work in progress) areas allows for a more condensed layout. This opens up space for additional production lines. Reduce floor space and there is less need for operators to oversee production areas.

- Flexibility: Our production lines are very unique because we have the flexibility to alter models being produced daily. We then decreased lead times as well for we have very minimal changeover times and downtime when switching models.

- Lead Times: Our production lines have lead times given to each model from understood takt times. This makes a very predictable value stream.

- Quality Control: We encounter much less wasted product and quality issues with the one piece flow process. You will find any quality issues or defective material on the first unit, and then revised/resolved for the next unit. Since batch sizes in one piece flow are just one, there will not be mountains of inventory to count, move, store, and dispose of.

- Identifying Future Kaizen Becomes Easier: Defects and WIP inventories will decrease, while issues on the shop floor will become apparent quickly. If problems relate to takt time or WIP, for instance, changes will quickly become obvious.

- Improves Employee Morale: Identify production problems immediately, and employees gain more ownership for their production area.

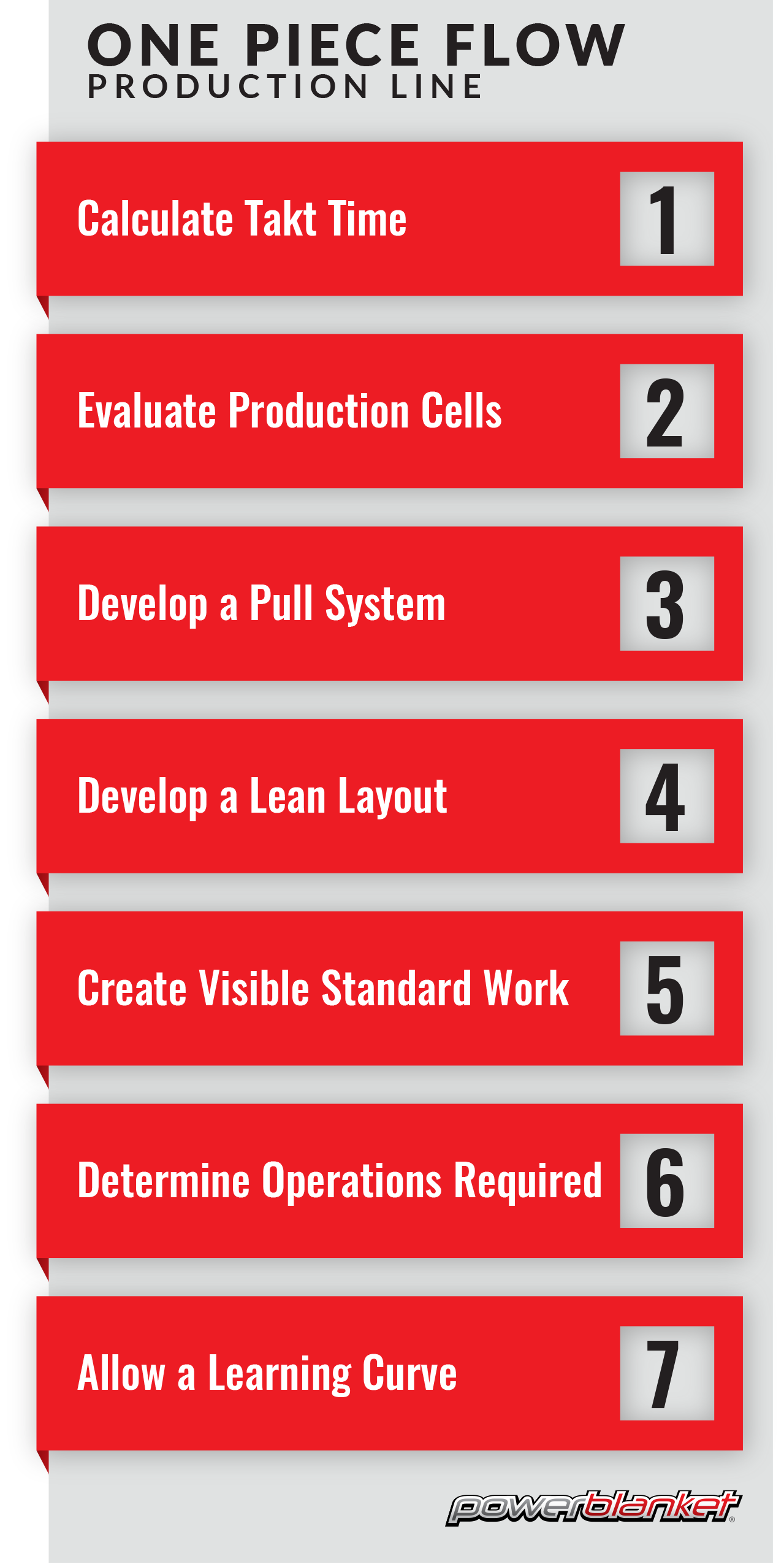

How to Create a Lean/Six Sigma Production Line

- Calculate takt time for products and ensure all cycle times are either less than or equal to total desired takt time.

- Evaluate production cells and base process/equipment capability on takt time. Considerations include changeover times, load and unload times, downtime, and machine speeds.

- Develop a pull system that allows for reduced lead times, ultimately benefiting customers. Allow for the value stream to drive the pull system.

- Develop a lean layout that allows for highest efficiency possible within the smallest amount of space. Space between process and within process cells must be minimal to eliminate motion waste and prevent unwanted WIP (work in progress) waste. Process requirements and factory floor limitations drive layout shapes and directions.

- Create visible standard work processes with the use of standard operating procedures, jigs/fixtures, quality checks, and 5S workstations. Standard processes eliminate variability and inconsistencies to drive quality. Consider accommodations for the differences between standard and custom products.

- Determine number of operators required to meet takt times. Train operators from standard work and cross train to allow for maximum flexibility.

- Allow a learning curve to develop and audit takt times and standard work over time to achieve maximum quality and efficiency.

Curious to see how Powerblanket can meet the unique needs of your industry?