Wind turbine repair is a highly skilled and specialized line of work. Wind energy turbines represent a significant investment of time, financial, and energy resources for any company. When repairs need to be made, they need to be undertaken quickly to reduce turbine down time.

How Do Wind Turbines Work?

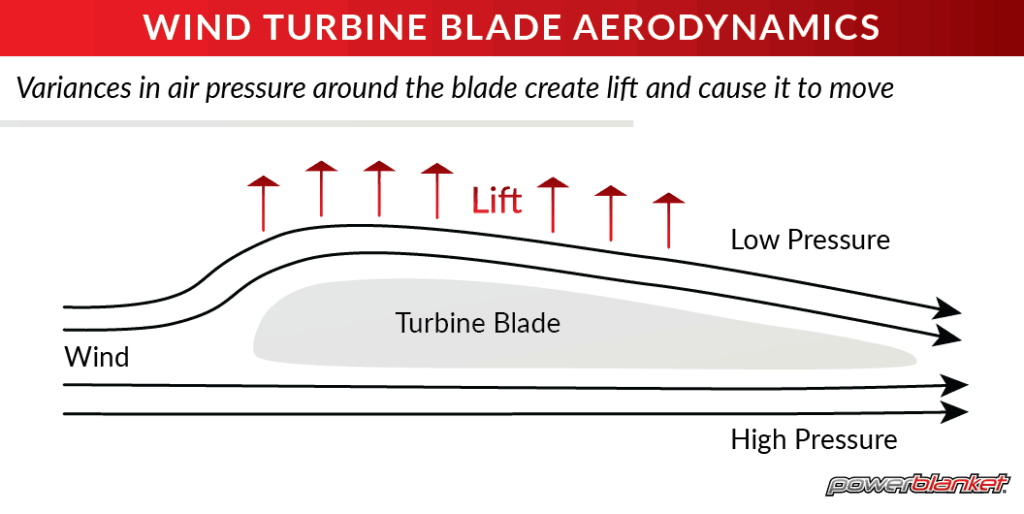

Have you ever wondered how wind turbines work? They look exactly like fans, but actually work in a completely opposite fashion. Fans use electricity to create wind. Wind turbines use wind to create energy. They accomplish this by using the same physical forces surrounding a plane’s wing.

As wind flows over the surface of a turbine blade, the pressure on 1 side of the blade decreases. The difference in air pressure between the 2 sides of the blade create lift and drag. The stronger lift force pulls the blade in 1 direction which causes the blades to spin. The blades attach to a rotor, which attaches to a generator. As the rotor spins the generator, electric energy is created.

Blade Maintenance

Mother Nature subjects wind turbine blades to a lot of stress. This includes bird strikes, lightning strikes, sand blasting, salt corrosion, rain, hail, ice, insects, and more. Erosion and pitting on the surface of the blade can ruin a turbine’s aerodynamic efficiency. When the aerodynamics of a blade are compromised, the turbine’s energy productivity is reduced as well.

Repair In The Field

After locking the blades in place, turbine repair service companies can reach the damaged area 1 of 2 ways. Sometimes their repairmen repel from the windmill to perform the repair. Another option is to use equipment or scaffolding to reach the repair site. Wind turbine repair often involves epoxy patch work.

Epoxy

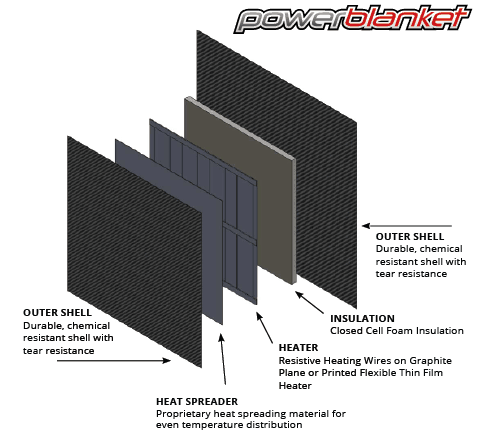

Work like this has been done for several years now, and more recently, these companies have discovered that the epoxy patches cure stronger if heating is applied evenly across the blade.

Heating blankets distribute heat evenly, rapidly cure epoxy, and cure to a stronger finish. This benefits service companies because they will be able to repair the turbines quicker. It also benefits the wind blade owners, because the sooner the blade is repaired, the sooner the windmill can be put back in use, generating and providing energy.

Curing Problems

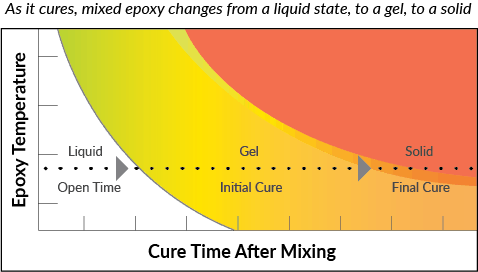

Most epoxy resin and hardener combinations require heat in order to cure since ambient temperatures are not high enough. Improper heating during curing of epoxy resins compromises its chemical, mechanical and heat resistance properties.

In cold temperatures, epoxy curing slows considerably. If temperatures drop low enough it will not cure at all. Warming the resin and the hardener before mixing can also help in winter conditions.

On the flip side, excess heat during curing causes bubbles and deformities. Carefully controlled temperatures and even heat without hot or cold spots is critical.

Improperly heated epoxy can also become discolored and yellow. Avoid using forced air heaters to apply heat during curing. Forced air heaters can make the epoxy look cloudy and ruin its glossy transparent finish.

Powerblanket Epoxy Curing Solutions

Epoxy Curing Blankets

Powerblanket epoxy and resin curing blankets use even heat distribution to cure epoxy patch work quickly and easily, and help to eliminate the huge financial burden of replacing entire wind blades. Our blankets are also heavily insulated to protect your cure from heat loss even in the coldest of weather conditions.

Contact us to find the perfect epoxy curing solutions for your needs at 866.957.5538 or [email protected].

Frequently Asked Questions

Can wind turbine blades be repaired?

Yes, wind turbine blades can be repaired by identifying and assessing the damage, removing damaged areas, preparing the surface, applying adhesive, attaching repair parts, and curing the repair with evenly distributed heat, such as from epoxy curing blankets.

How much does it cost to repair a wind turbine blade?

Repairing a wind turbine blade can cost up to $30,000, which is significantly less than the $200,000 cost of a new blade.

How much do wind turbine blade repair technicians make?

Wind turbine blade repair technicians earn an average salary ranging from $60,190 to $62,390, depending on the state.

What is the life expectancy of wind turbine blades?

Wind turbine blades typically have a designed lifespan of 20 years, though they can sometimes remain in use for up to 25 years.

Cure your epoxy resins faster and easier than ever before with Powerblanket.