How productive is your construction crew? Are important tasks always completed on time, or is it usually a frantic race to the finish? Here are 5 ways you can improve your company’s construction productivity and regularly meet your important deadlines with ease.

How Productive Is Your Construction Company?

Productivity: It’s a word that gets tossed around a lot, especially as it relates to any business operation. Productivity is the ability to maximize results with a modest amount of resources – in other words, doing more with less. Getting more out of something than you put into it. Productivity is about increased efficiency. And at the end of the day, it is about regularly achieving the well-defined goals of your company.

Now let’s talk more specifically about your construction company’s productivity. Your team works on projects to reach common goals. When things go according to plan, it is a low-friction, rewarding experience. However, when a given project seems to move along at a snail’s pace, it can frustrate workers, management, and clients. Especially when it is unexpected.

For example, failing to complete a large building project may interrupt a business’s ability to open on time.

How about a slow-moving concrete project that may affect local businesses’ abilities to get customers in their doors? This leads to unsatisfied customers and unwanted complaints. It’s a no-win for anyone.

When the timing of your projects are less-than-satisfactory, they also affect your company’s wallet, leaving modest profit margins. As a result, company growth can become largely stunted. Simply put, in order to have a well-oiled operation, you must become a master of productivity in order to beat out competitors and experience continual productivity growth in the construction industry. Now that sounds like a pretty good win!

So let’s discuss 5 ways to not only improve, but truly master, your company’s construction productivity.

1- Plan, Plan, Plan

Abraham Lincoln once said “Give me six hours to chop down a tree and I will spend the first four sharpening the axe.”

The most efficient way to approach any project is with a clearly-defined plan, complete with easy-to-identify goals and processes along the way.

However, many people make the mistake of simply jumping into a project because they are excited to get started and make necessary headway. But wait just a second. Don’t make the mistake of starting before you’re actually ready, giving no thought to all that is involved beforehand. That’s a sure-fire way to waste precious hours.

With a clear plan, you know from the beginning exactly how much your input costs should be, and you can even find ways to reduce costs by knowing exactly how many people you need on your team rather than paying a few people to act as unappointed “supervisors.” (Because seriously, nobody loves those.)

You will have enough time to find the best workers for the given job, which means they have the experience necessary to work quickly, efficiently, and without error. After all, no construction company wants to deal with fixing sloppy work – and angry customers who trusted your company.

In addition, smart planning allows for the avoidance of simple oversights like, say, not checking the weather and being forced to delay an important project due to relentless rain. Scheduling in some extra days to pad the project’s timetable allows for peace of mind on your end, timely completion, and satisfied customers.

2- Train Your Staff Thoroughly

Ideally, you will have found a previously, well-trained team of workers in the industry to complete the job without a hitch. However, if you have a team that is not completely experienced in the projects your company works on, it is best to take the time to thoroughly train them before getting started. After all, this is your company’s reputation on the line, right?

Appropriately training your team includes:

- Clearly communicating exactly what your end goal for each project is.

- Breaking down the end goal into very specific, check-off goals that should be met every single day before the workers go home for the evening.

- Creating a visual representation of the tasks to be completed each day. Consider hanging a large white board where your crew can easily check its progress and mark each completed task along the way. Verbal instructions alone may be easily forgotten or lead to mistakes.

- Physically showing your team exactly how to perform specific tasks. Teach your crew the exact “do’s and do nots” of each process. Failing to do so leaves a lot of room for personal interpretation, which may lead to a job done unsatisfactorily.

- Allowing for supervised practice

In the construction industry, one of the quickest ways to reduce productivity, and lose out on big profit margins, is to fail to supervise a team of new workers, only to find that a project needs to be reworked. Ouch. Do the work correctly the first time and avoid the headache! Remember, construction productivity is all about maximizing your results with the least amount of resource input.

3- Be Flexible and Listen To Your Team

This recommendation may seem strange, having just read that you should know exactly what should be done each day to reach your ultimate goal, as well as clearly communicating it to your team. But here’s the thing – you also need to be present on the job often and listen to your workers because, in the end, they are the ones who are doing the labor day in and day out. Asking your workers how the projects are going on a regular basis, and what you can do to improve their productivity, allow your workers to express their insights and experience on the job. They may very well provide a needed look into the project that you had not anticipated.

If you’ve ever worked for someone who is not willing to listen, you know just how frustrating it can be. Don’t be that boss. Listen, learn, and improve your processes daily.

Listening to your staff with open ears allows you to adjust the project as necessary to reach your goal, or potentially increase the productivity of the project. Listening means hearing what your workers are telling you without judgment or immediate reaction. It means truly being open to doing things a bit differently and thinking about ways to consistently improve from the suggestions offered. This gives your team the confidence to approach you in future situations as well, which allows for consistent productivity growth in your business. And in the end, growth is the goal.

Worried that allowing for changes in the plan may be taking a step backward in the project’s progress? This is where the planning factor is so important. As mentioned earlier, when you have given the project a bit of time padding to allow for issues that may arise, you can take the suggestions in stride and provide the best results for both your company and your customers.

4- Use Quality Vendors

Refuse to work with unreliable vendors.

If you’ve worked in the construction industry for a while, you know that all vendors are not created equal. Working with vendors who are simply not reliable can wreak havoc on your productivity.

The best advice for finding vendors is to simply do your research. Don’t go with the first company you find simply because it takes effort to dig a bit deeper. Compare several vendors in the same industry. Look at price, but also look at the company’s practices themselves. Are the company reviews from previous customers positive?

As mentioned earlier, planning ahead gives ample time to find the best vendors to suit your company’s needs and projects. Allow for that time in order to avoid unnecessary headache during a project.

Vendor quality goes far beyond simply offering the products your company needs. Your company’s success depends on completing jobs in a timely manner, and your ability to do this depends on the timely service of your vendors. If you have a vendor that is constantly placing your products on backorder, messing up orders in the first place, or has a difficult customer service staff, the time delay is just not worth the hassle. Your ability to give your customers your best depends on your vendors giving their best to you.

Choosing wisely in the first place will improve your productivity greatly, so don’t underestimate this factor in your company’s growth.

5- Use Reliable Equipment

We’ve discussed the importance of using quality vendors in order to keep your projects cranking within the appropriate time frame. It is also incredibly important to find vendors that offer high-quality products. This seems like a given, but some construction companies may be tempted to go with the cheapest options available in order to cut costs and increase profit margins.

Avoid this temptation.

Choosing to work with cheap equipment may result in

- Equipment breaks and malfunctions during a critical time in the project.

- Subpar overall results, and reduced customer satisfaction.

- Setbacks in the project timeline.

- Increased stress for the project manager and crew

- Loss of potential profits

Simply put, it’s essential to do your research when it comes to the equipment your company will use on projects to deliver the best results possible. Best results will lead to word-of-mouth referrals and more projects, and ultimately profits, for your company.

It’s also important to constantly be aware of the new tools and equipment that can allow your team to work more quickly and efficiently. While these tools may be an investment initially, they often save countless hours, which will ultimately save your company hard-earned dollars. You’ll be able to save money on the payroll, and you’ll be able to increase turnaround on projects, allowing for your company to take on more work.

It’s all about the long-game, and it’s important to do your research to know where to invest to help your company grow the way you need it to. Don’t get stuck thinking that you can still use your outdated methods when newer ones are available. It’s likely that your competition is using the newer, time-saving methods, so improve along with the competition. As a simple example, a construction team that still uses a hammer and nails is going to waste several hours working on a project that could be done more efficiently with a nail gun.

Consider other ways to improve the overall efficiency of your system of operations through other types of equipment. This may include communication tools to keep things running smoothly between your team and management. Constantly be looking for ways to improve your efficiency, and you’ll be amazed what you will find.

Powerblanket: Your High-Quality Vendor of Reliable Heating Equipment

When it comes to offering high-quality products that aid your company’s productivity, Powerblanket has the right construction heating solution for you. Our mission is to keep your construction projects moving smoothly and to help you avoid surprise issues that could bring your progress to a screeching halt.

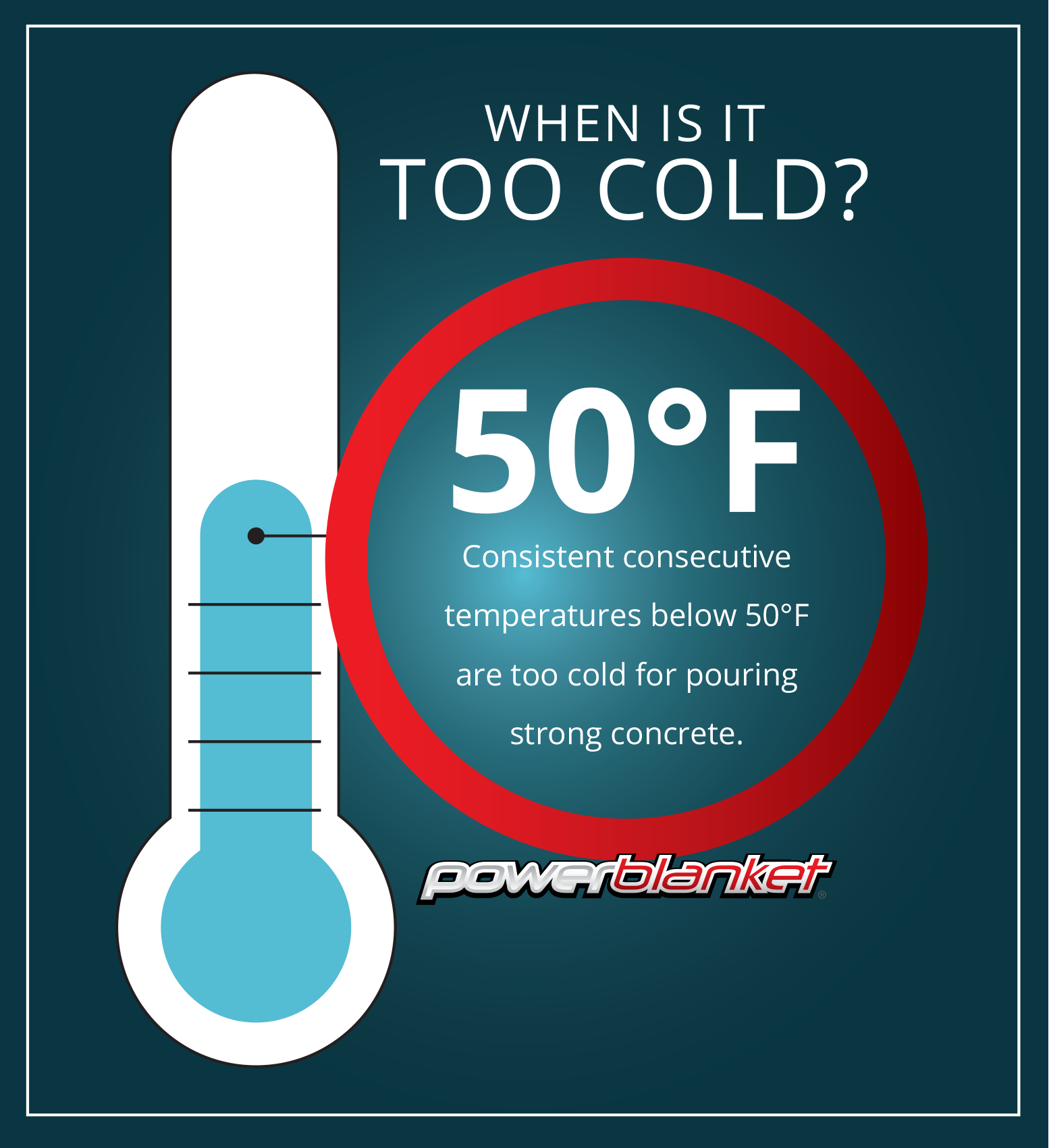

At Powerblanket, we offer a high-quality, top-of-the-line heating blankets that protect against the harsh realities of extreme weather, particularly in the frigid winter months with freezing temperatures.

- Need to thaw out frozen ground before you can begin digging?

- Ready to effortlessly cure that concrete without dealing with weakened results due to unforgiving winter air?

- Need to store your expensive, valuable materials at the right temperature without worrying about frozen, unusable product when you need it most?

Whatever your company’s particular heating needs, Powerblanket is the answer.

Here at Powerblanket, we are committed to increasing your productivity and helping your company experience continual growth.

Contact us today at 801.506.0198. Our friendly staff is available to answer any question you may have about your heating needs. We will get you on the road to the productivity growth your company deserves!

Frequently Asked Questions

How can we improve the level of productivity in the construction industry?

To enhance productivity in the construction industry, focus on meticulous planning, continuous staff training, effective communication, and leveraging technology to streamline operations.

Which of the following could increase productivity in the construction industry?

Clear communication is crucial for boosting productivity, as it ensures everyone is aligned with project goals and updates, minimizing misunderstandings and delays.

What strategies can be used to improve productivity?

Implementing clear planning, regular goal reviews, and minimizing time-wasting activities are key strategies to maximize productivity in construction projects.

How to be more efficient in construction?

Efficiency in construction can be improved by thorough planning, listening to staff feedback, investing in training, and maintaining open communication channels.

Don't let the cold weather stop you, and keep your construction project on schedule. Powerblanket has you covered.