Waiting for the curing of concrete can easily test patience, especially when you’re ready to move on to the next step of a project. However, it’s important to remember that quality is the end goal, not quickness. Rushing ahead and not allowing enough time for concrete to properly cure before allowing foot traffic or heavy machinery to travel across your newly placed cement can seriously compromise the integrity of a concrete slab.

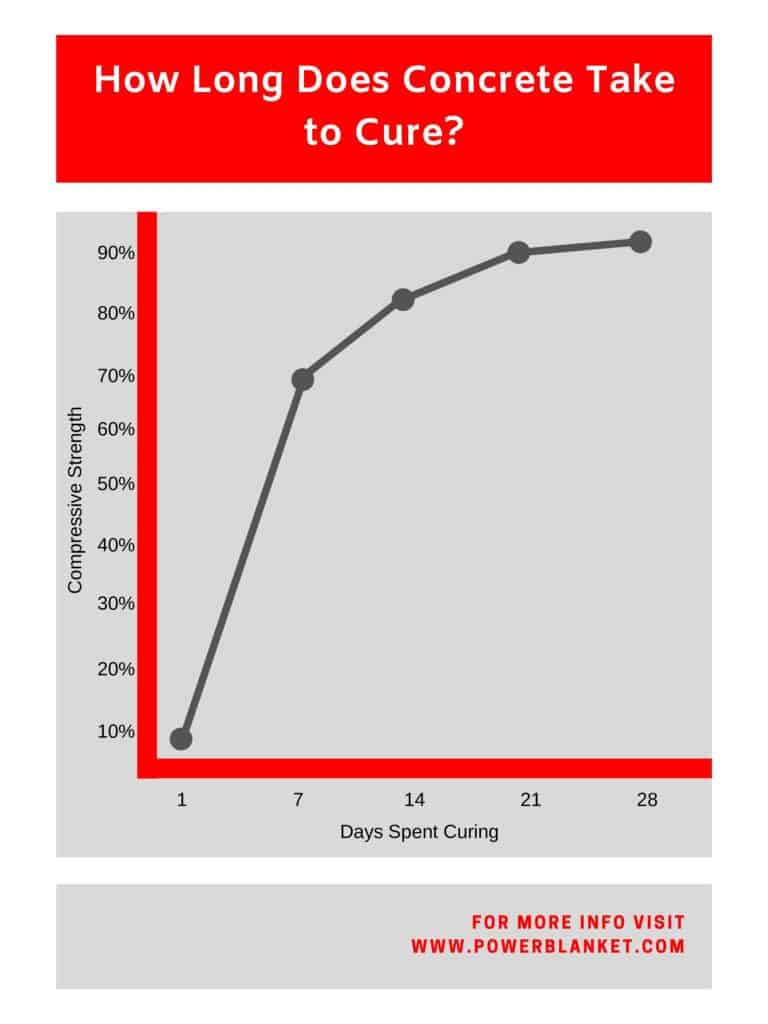

Concrete experts use the “70 in 7” rule to know when concrete has hardened enough. After 7 days, concrete has reached 70% specified compressive strength and can handle most loads.

The Best Dang Concrete Recipe

You can’t properly cure concrete if you don’t understand what it is. Concrete is made up of three parts: cement mix, water and aggregate. All three work together to form durable, reliable concrete.

Cement

Cement.org reveals the details about what makes up cement:

“Cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminum, iron and other ingredients. Common materials used to manufacture cement include limestone, shells, and chalk or marl combined with shale, clay, slate, blast furnace slag, silica sand, and iron ore.”

Depending on the brand or pouring situation, some concrete manufacturers will include additives in the cement mix to help the concrete cure faster or cure under unfavorable pouring conditions, such as cold weather or high humidity environments. Typically, most mixes consist of 10-15% cement.

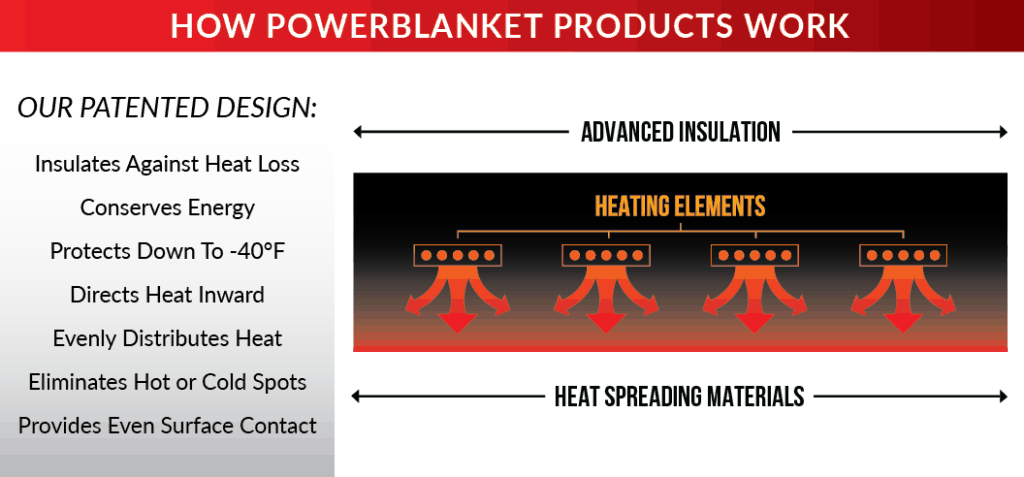

Our concrete curing blankets are designed specifically to accelerate concrete curing. Our patented heating element heats evenly across the entire blanket surface to prevent cold spots. The rugged, waterproof outer shell protects the heating element from moisture and abrasion. With multiple size options available, Powerblanket has a concrete curing blanket suitable for any job.

Water

Concrete curing is most dependent on how much water is added to the mix. Too much water and the concrete will be very porous, leading to cracking and chipping. Not enough water and the cement and aggregate won’t combine together. High water-to-cement ratios are used when concrete needs to be fresh and malleable while curing. Low water-to-cement ratios are used for increased durability and tend to cure faster. Depending on the aggregate used, most cement mixes use 15-20% water.

Unless you’re pouring concrete in cold weather, the type and temperature of the water don’t matter. When temperature is a factor, use hot water in your concrete mix to help prevent it from freezing within the concrete.

Aggregate

Sand is the most common form of aggregate, though nearly any rock-like material can be used so long as it is crushed. Even broken chunks of concrete are excellent as aggregate. When added to the mix, cement, and water form a paste that binds the aggregate together in a process known as hydration. After all three are sufficiently mixed together, the newly formed concrete can be poured and begin curing.

Cement Curing Factors

Several factors influence the curing time of concrete, including:

- Mixture proportions- Increasing cement to water ratio will decrease setting time but may compromise long-term strength.

- Type of mix used- Fast-curing concrete mixes and add-ins are available for accelerated curing

- Specified strength

- Size and shape of slab

- Ambient weather/temperature- Higher temperatures decrease initial concrete setting time but may decrease long-term strength.

How Long Does Concrete Take to Cure?

Concrete never stops curing, with its strength only growing through time. It becomes safe to walk on 2-3 days after pouring, but it shouldn’t be considered “set” until it has been set for at least a week.

After initial placement, concrete increases in compressive strength very quickly for 3-7 days, then gradually for the next three weeks. The curing time of concrete is typically 24-48 hours, at which point it’s safe for normal foot traffic. After one week, concrete is typically cured enough to handle continued construction, including heavy machinery. Concrete is recognized to have reached full strength 28 days after placement.

The “70 in 7” Rule

When determining how long concrete takes to dry, remember the “70 in 7” rule: Most concrete mixes will have reached 70% of specified compressive strength after 7 days. At this point, it’s ready for exposure to normal traffic.

Concrete Curing Blankets

Unfortunately, cold weather during winter months can seriously slow down concrete cure time and significantly hold up construction projects. The best temperature to cure concrete is above 50° F, which can be difficult to replicate if the air is below freezing.

Harder, Better, Faster, Stronger

Luckily, solutions, such as concrete blankets that maintain optimum temperatures during cure time, are available. Concrete curing blankets are an effective option that cure concrete 2.8 times faster than a typical insulated blanket and properly maintain moisture throughout the hydrating process. Concrete blankets are easily transported and installed and maintain ACI compliance for cold-weather concreting. If you’re looking for a solution to maintaining optimum concrete cure time during cold winter, using a concrete blanket is the best method for drying and curing concrete.

Frequently Asked Questions

How long does it take for 4 inch concrete to cure?

A 4-inch concrete slab typically takes 24 to 48 hours to set enough for foot traffic, 7 days to handle vehicle traffic, and reaches full strength at 28 days.

How long should concrete cure before putting weight on it?

Concrete should cure for at least 24-48 hours before supporting light foot traffic, 7 days for vehicular traffic, and 28 days to achieve full strength for maximum durability.

How strong is concrete after 7 days?

After 7 days, concrete generally reaches about 70% of its specified compressive strength, making it suitable for most construction activities.

How long to let concrete cure before removing forms?

Forms can typically be removed after 24-48 hours, once the concrete is solid enough to support foot traffic without leaving marks.

Cure your concrete faster and better in cold weather conditions with Powerblanket.