When you’re dealing with epoxy during less than favorable weather, it’s not always about freeze protection. In fact, some epoxies will only cure properly in conditions above room temperature. This makes it nearly impossible to cure epoxy in cold weather, unless you have the proper solution, that is.

9 Things to Consider When Curing Epoxy

A good majority of epoxy resins and hardeners require high temperatures in order to cure. Since ambient temperatures are almost never high enough, even in an Arizona summer, epoxy needs assistance to cure fully and properly. If the epoxy resins are not heated high enough and evenly enough, the chemical, mechanical, and heat-resistance properties become compromised. In fact, some epoxy resins require heating in steps to prevent overheating from exothermic reactions.

With all of this in mind, there are several matters you should consider when choosing a solution for your epoxy-curing needs. Here are nine specific guidelines that will help you find a product that will enable proper curing in all the areas concerned:

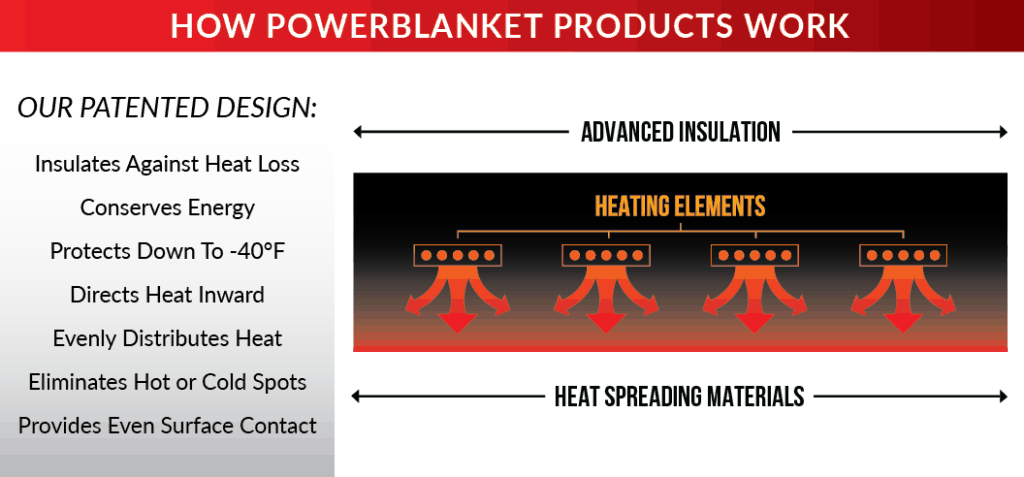

- Prevent uneven gloss and poor inter-coat adhesion by finding a solution that evenly heats over the entire surface area. When dealing with a heating solution, it’s easy to discover any number of methods or products that will heat the respective surface. However, merely heating the surface isn’t all you need. You need to be able to apply an even distribution of heat to the entire surface area in order to ensure that you get the proper gloss and inter-coat adhesion. So in short, spotty heating applicators won’t cut it.

- Since the warmer the resin and hardener, the lower the viscosity, find a heating solution that will maintain the proper application temperature. Some products and methods of heating surfaces are like stove top ranges, meaning there aren’t a whole lot of options. If you come across a solution that only has the choice of hot and extra hot, there’s no way you’re going to be able to maintain the ideal temperature for your epoxy curing. You need something you can bring to the ideal temperature and keep there for the duration of the epoxy resin process.

- Since a cool epoxy resin is more difficult to meter and mix with a hardener, find a customizable heating solution that will properly fit the size and shape of your application to maintain maximum control. Not only do you need heating capabilities for the curing process, but you need them for proper application too. This is where a handy heating apparatus able to fit the bucket, drum, or barrel your mixing in becomes invaluable. And again, it has to do more than just heat. It has to maintain temperature.

- Ensure less maintenance downtime by finding a heating product with a track record of performance. No one wants to chance wasting time and money on an experimental solution. You need something that you know will work time and time again.

- Ensure that the epoxy resin and hardener will flow through dispensing pumps easily by maintaining the appropriate heat. This goes back to the third point mentioned. In order for you to push a cool and viscous epoxy resin through any applicator without a hitch, you need first to heat it and bring the viscosity down.

- Ensure more cross-linking by warming the materials while mixing to initiate a better chemical reaction. Back to mixing again—for the proper chemical bond, you need ideal temperature. Thus, the ideal solution would work both for the curing and mixing process, and would have a positive effect on cure time.

- Prevent air bubble entrapment and safeguard the strength and effectiveness of the epoxy by having the right heating solution. If your epoxy isn’t mixed at a high enough temperature, it could bubble and compromise the strength and longevity of the finished product.

- Prevent contamination by not using kerosene or propane heaters, since they can inhibit the cure as well as contaminate epoxy surfaces. There are numerous reason why kerosene and propane heaters don’t work well as heating solutions for epoxy curing, and the possibility of contamination is only one of them.

- Prevent under-curing, as it can cause de-laminations and product failures. This can only be done by finding an evenly-heated and temperature-controlling solution. Lastly, if your epoxy doesn’t fully cure because of temperature lows, it’s simply isn’t going to last, or look right—for that matter. To prevent this, you need to find a solution that applies the previous 8 guidelines.

The Powerblanket Solution

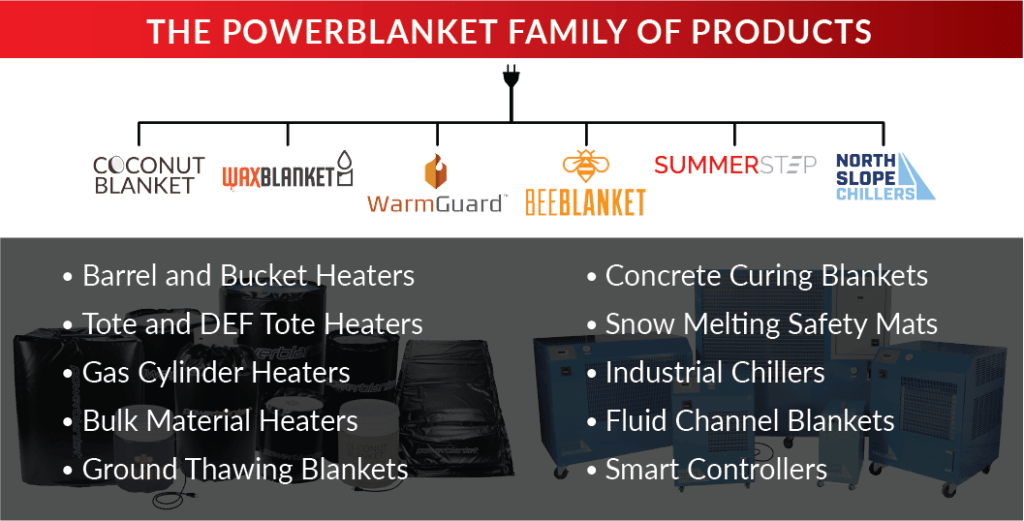

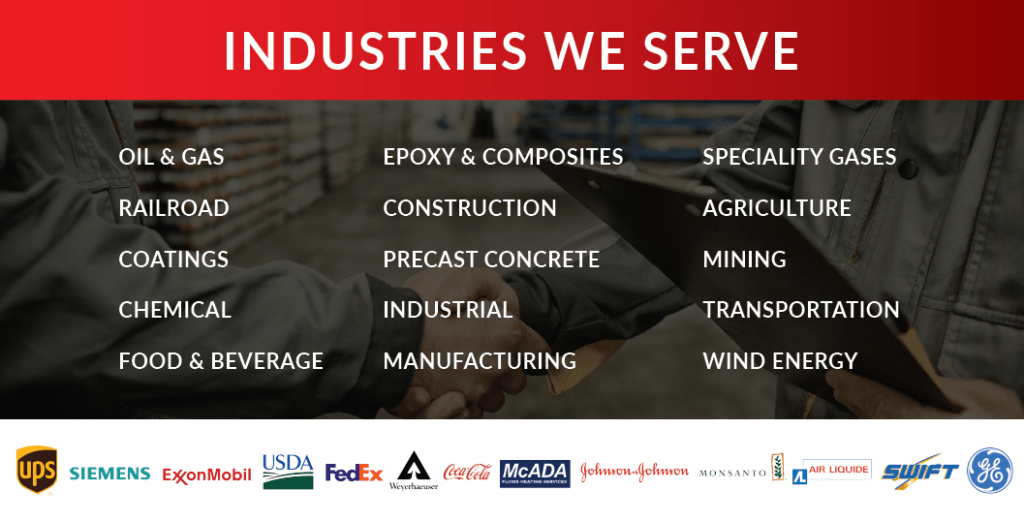

Thankfully, with Powerblanket patented heating technology, you don’t have to worry about the challenges epoxy poses on itself anymore. As far as the curing process is concerned, Powerblanket offers epoxy curing blankets that provide a temperature-regulated, even-distribution of heat that will enable your epoxy to cure under ideal conditions. The standard high watt density epoxy curing blankets cure and post cure epoxy resins at temperatures up to 180° F and 80 watts per square foot.

Benefits of a Blanket

Powerblanket’s epoxy curing blankets offer many benefits to your business:

- Even heating: heat put out by an epoxy blanket is equally spread across the blanket.

- Effective in any environment: works in any weather, any time of year.

- Save time and money: epoxy blankets are cheaper than other epoxy curing solutions and are quick to assemble and takedown.

- Safety certified: employees won’t get burned if they need to move the blanket while in operation.

- Easily installed an operated: just lay it down, plug it in, and watch the magic happen.

- Remote monitoring options: combined with Beacon control technology, epoxy curing blankets can gather curing and temperature data while being controlled offsite.

- Custom solutions available: if you don’t see the size available for your needs, talk to us about a custom solution for your epoxy curing project.

- Peace of mind: don’t sit and fret over temperatures and curing times. Epoxy blankets made by Powerblanket are built to let you be at ease and focus on more pressing issues. Temperature control is important, so let us handle it while you do what you do best.

For storage and application, Powerblanket also offers barrel, drum, and bucket heaters that allow you to heat your epoxy to the ideal temperature, and in a very economical way too. Every Powerblanket product is ETL certified to the same high electrical standards as other Nationally Recognized Testing Laboratories such as UL and CSA.

For more information, call 855.972.2314 or email [email protected].

Cure your epoxy resins faster and easier than ever before with Powerblanket.