Whether you’re on the job site, tailgating before the game, or taking your RV out in winter months, you’ll need to put your trust in your propane tank to keep the operation rolling.

Propane, sometimes referred to as liquid petroleum gas, is an eco-friendly, safe, and low-cost option for powering your home appliances or business operations. Propane is multifunctional, stores easily, and has a long shelf life. It’s still crucial, though, to store propane tanks or cylinders properly to keep you and your propane safe all year long.

This year, be prepared when colder weather arrives. Cold temperatures often have adverse effects on equipment and materials like propane tanks, especially when the job requires every moving part to go smoothly. Without an effective solution to these freezing temperature problems, the project stops, time and money are lost, and you suffer.

Staying warm in frigid temperatures is not always easy. Make it simple with a propane tank heating system designed to provide safe, consistent heat no matter the weather. Learn how to keep propane tanks from freezing and make the most of your propane tank pressure by preparing it for cold weather conditions.

Does Propane Freeze?

Technically speaking, yes, propane can freeze. The propane isn’t what you should be worried about, though, but rather the tank. If liquid propane falls below -306°F, it will freeze. Inside of the tank, propane is found in a liquid form. Luckily, propane tanks are built to protect propane and utilize its heating capabilities in its gas form. As liquid propane leaves the tank, it reaches its boiling point (-44°F) and returns to a gaseous state, powering your grill, water heater, or other appliances.

While it’s extremely unlikely that you’ll find yourself or your propane tank in temperatures this cold, your tank and its functions will still be affected by general cold weather. Low pressure, minimal production, and weathered or deteriorated tanks are a few of those effects. Read on to learn some helpful tips for protecting your propane tanks from freezing conditions.

Keep It Full

What’s one of the best ways to prevent your propane tank from freezing? The answer’s simple: keep it full. Skip the exchange and refill your tank more often. Not only is it cheaper, you’ll save yourself from the inconvenience of a frozen tank. According to U-Haul, a company that many are surprised to learn offers propane refill services, you can save an average of $1.76 per gallon if you refill your propane tank instead of exchanging it. Not only that, you won’t let any propane go to waste if you choose to fill it up before it’s completely empty.

Keep Up the Pressure

Propane contracts as temperatures drop, so the colder the ambient weather, the slower the flow will be. This change in the rate of pressure can cause your tank to “freeze up”. As the temperature drops, the total volume of liquid propane in your tank drops, and so does pressure. In conditions as high as 60°F, you may have noticed an obvious change in the pressure of your propane tank.

There are more than a few ways to avoid low-pressure propane tanks. One of those is by keeping it full as often as possible. Depew Energy suggests that you keep your propane tank at least 30% full at all times to maintain positive pressure.

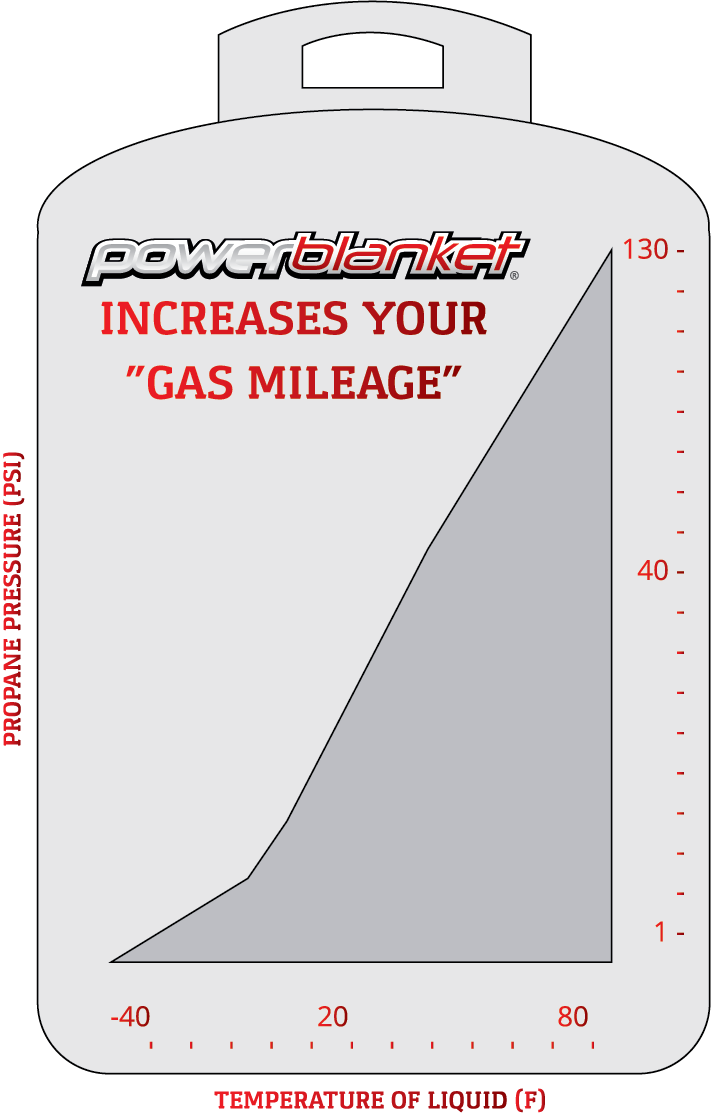

The warmer your propane tank is kept, the higher your pressure output will be. Refer to the chart below to determine the ideal temperature for your desired PSI.

When utilizing an option like a heated blanket to keep your propane tank warm, it is important to know how many watts are necessary to obtain the PSI levels desired or required. If it is not possible to calculate this yourself, you will want to look for a solution that can provide that information for you before you make the investment.

Check out this article for more helpful information on propane pressure upkeep.

Ways to avoid pressure problems:

- Keep propane tanks and regulators clear of snow

- Maintain propane tank warmth using a heating blanket

- Keep the tank full, never let it drop below 30%

- Always store propane cylinders in an upright position, never upside-down or on their side

- Protect your tank from freezing due to outdoor elements, but always keep it outdoors in a well-ventilated area

- When not in use, be certain that the propane tank gas valve is turned “off”

Keep It Stored

Where should you store your propane tank? It’s best to store your propane tanks in a well-ventilated and cool area. While it can be tempting to keep your propane in a temperature-regulated area like a garage or a basement, the potential dangers aren’t worth the risk.

The ideal place to store your propane tanks is outdoors in a shaded, dry place. Rain, snow, and humidity cause rusting, which deteriorates the tank and decreases its lifespan.

What sort of temperatures can a propane tank withstand? According to Amerigas, you should avoid storing propane tanks at or subjecting them to any temperatures above 120°F and below -40°F. While those are extreme temperatures on both ends of the spectrum, it’s wise to take extra care by never storing your propane tanks in direct sunlight and always keeping them clear of ice and snow.

Keep It Warm

Depending on where you work or live, storing propane tanks outdoors means keeping them in freezing conditions. We get that it’s not an ideal situation and likely a recipe for low tank pressure and a bad headache. There are plenty of solutions, however, for when you need to store propane tanks outside in winter conditions.

To avoid tank freezing and low pressure, keep the tank free from any ice, sleet, or snow buildup. If it snows, clear off the tanks, valves, and regulators immediately. Not only will this keep them warm and well-pressurized, but you’ll also save them from rust and unnecessary wear.

Another solution would be to utilize propane tank heating systems. Try to find a heating method with safe heat, such as a heating blanket or insulated blanket, depending upon the amount of pressure needed. Look for a heating solution that offers consistent heat and complete coverage. Keeping liquid propane at warmer temperatures will increase the pressure output and save you the headaches that come with low PSI. This constant regulation of tank temperature could be what saves your bacon during winter conditions.

Need to protect your propane tank from freezing? Give us a call and talk to a Powerblanket heating expert today. 888-316-6324, or visit our Propane Tank Heater page HERE.

Frequently Asked Questions

How cold is too cold for propane tanks?

Propane tanks can withstand temperatures as low as -40°F, but it's crucial to maintain tank pressure and prevent freezing by keeping them at least 30% full and using heating solutions like blankets.

Why did my propane tank freeze on the outside?

Frost on the outside of a propane tank usually indicates rapid vaporization due to heavy use or low temperatures, which can cause a drop in pressure.

What can you use to insulate a propane tank?

To insulate a propane tank, you can use heating blankets or insulated covers designed to prevent heat loss and maintain consistent pressure in cold conditions.

What is added to propane to keep it from freezing?

Methanol can be added to propane to prevent freezing by inhibiting any water present from solidifying, but maintaining proper tank pressure and warmth is also essential.

Keep your propane tanks at the perfect pressure with Powerblanket.