Compressed gas is invaluable to many operations – both at home and across various industries. Of course, you can probably guess that the amount needed in a large-scale business production is going to be far greater than that needed to keep a residential water heater running. The good news is that gas can be compressed, and “bottled,” into the size specific to your situation.

Not sure what size that would be? We’re here to help.

Powerblanket propane tank and gas cylinder heaters provide the safest, most effective heating solution for gas cylinders of any size. With even heat distribution across the entire tank, you can optimize gas usage efficiency even in frigid temperatures.

Common Uses for Compressed Gases

Compressed gas cylinders were first invented and used way back in 1880, becoming a major part of the medical field. Shortly after, several companies joined the business of “bottling” various gases. One such company is Air Liquide. Founded in Paris in 1902, Air Liquide is now one of the largest world suppliers of compressed gases, serving industries such as healthcare, construction and engineering, electronics, and more.

The compressed gases that are widely distributed include propane, nitrogen, chlorine, helium, carbon dioxide, acetylene, and oxygen. They each serve different functions and industries. It is likely that one of the main compressed gases you will be working with, especially at home, is propane.

Before we jump into sizing, here are some of the many ways compressed gases (and particularly propane) can be used – both at the home level and the industrial level.

Residential:

- BBQ Grills

- Water Heaters

- Fireplace

- Stove

- Clothes Dryer

- Lighting Fixtures

Industrial:

- Propane-Powered Forklifts and Other Small Vehicles

- Large Operational Appliances

- Nuclear Power Production

- Oil & Gas

- Pharmaceuticals

- Creation of Foods

- Water

- Mining

- Steelmaking

- Welding

Common Compressed Gas Cylinder Sizes

Gas cylinders are sized by the amount of liquid they hold or by their weight. You may be wondering what size you need for your specific situation. Here are the most common cylinder sizes.

- 20-Pound: This is likely the size you’ve seen the most, especially if you’re a fan of firing up the grill on summer nights. This size is easily portable and also services appliances like patio heaters and mosquito catchers.

- 33-Pound: This size is often used in a construction setting. It is often used on propane-powered forklifts and various small vehicles. 100-Pound:

- The 100-pound cylinder is often used residentially and services many household appliances. It is also used for gas-powered fireplaces, stoves, and clothes dryers.

- 500/1000 Gallon Tanks: Quite the tank size jump, right? This size is often used for heating an entire home or for powering large appliances. It is also used in small commercial businesses for various functions.

- 30,000 Gallon Giant: This definitely isn’t a size you’re going to find hanging out in somebody’s backyard (although that would be quite the BBQ!) This “Giant” is found in propane storage facilities or large industrial sites. It can also be found in certain housing communities that share one common gas source.

Unless you’re running quite a large business operation, it’s likely you’ll be sticking with one of the smaller, portable compressed gas cylinders.

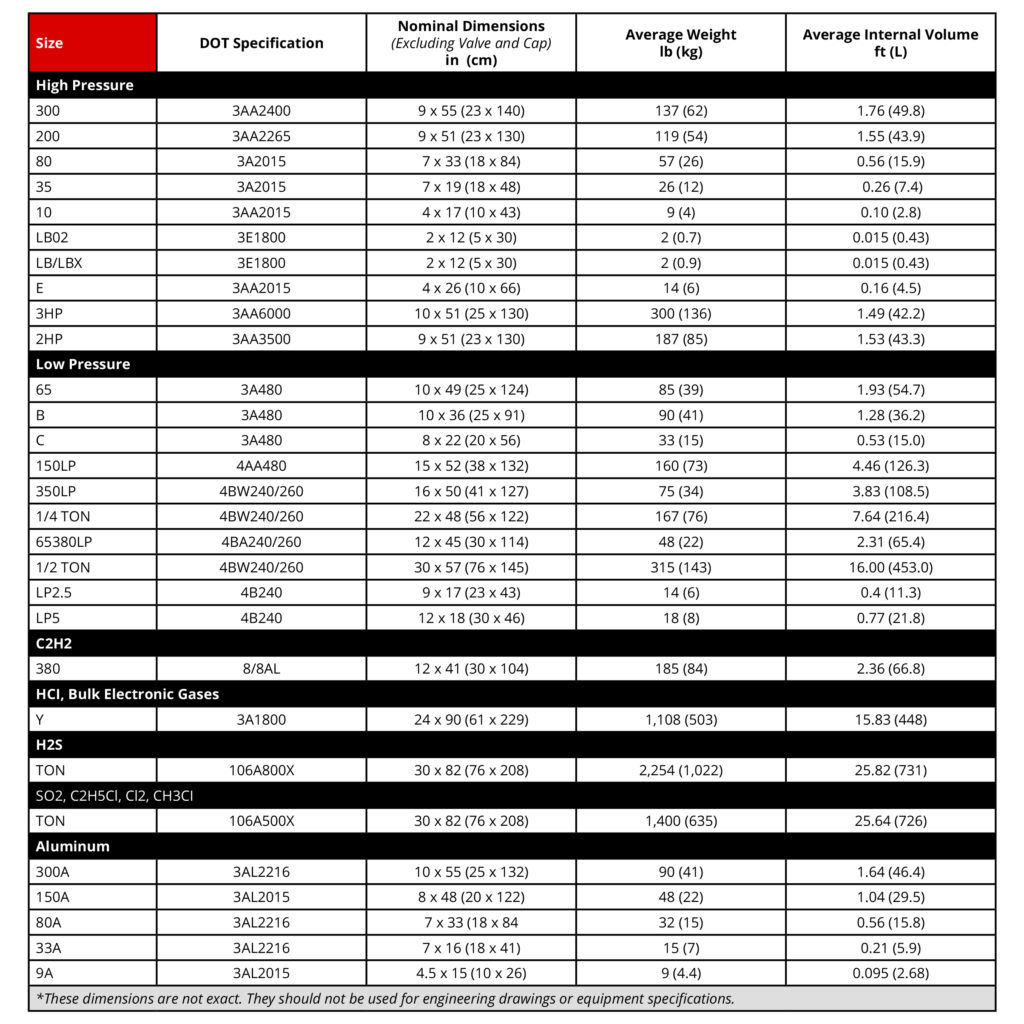

For more detailed information on the several specialty gas cylinder sizes and specs that are available to fit your needs, here’s a detailed chart that will help.

Cylinder Sizes and Safe Temperature Regulation

When the temperature drops, maintaining optimal pressure in a liquefied gas cylinder can be incredibly difficult. Cold external temperatures prevent the liquid from vaporizing, which makes your gas cylinders unusable because of low pressure.

No matter what specialty gas you use – and regardless of the size you need – it is important to keep safety practices at the forefront of your mind. If your high-pressure cylinders are handled roughly or allowed to reach high temperatures without proper regulation, they are at risk of exploding without warning.

Whether your cylinder is large or small, the effects of an explosion can be devastating.

Because compressed gases can be a huge hazard if not handled properly, it is absolutely essential that you carefully regulate the temperature where it is stored. Your safety, and the safety of those around you, depend upon it.

One of the easiest, most effective ways to safely regulate the temperature of your high-pressure cylinders is with a safe, dry heating source applied directly to the tank.

Choose a Powerblanket Propane Tank Heater

Powerblanket specializes in safely heating gas delivery systems for homes and businesses alike. When it comes to gas temperature regulation, we are always here to help.

Here at Powerblanket, we offer a variety of gas cylinder heating options, with sizing to fit any tank you have with exactness. Our gas cylinder heaters provide a uniform barrier of heat across the entire cylinder. Our top priorities for our customers are always safety and heating efficiency.

No matter what size, we have propane tank heaters that will cover it.

Here are some top reasons to choose a Powerblanket cylinder heater:

- Increase performance and efficiency of gas cylinders

- Save money by optimizing gas and material usage

- Provide even heat distribution

- Reduce cylinder refills in cold temperatures

- Safety certified to UL and CSA standards

Give our expert Powerblanket team a call at 866.945.4203 today.

Powerblanket's superior heating solutions reduce costs by optimizing container temperatures and increasing cylinder efficiency.