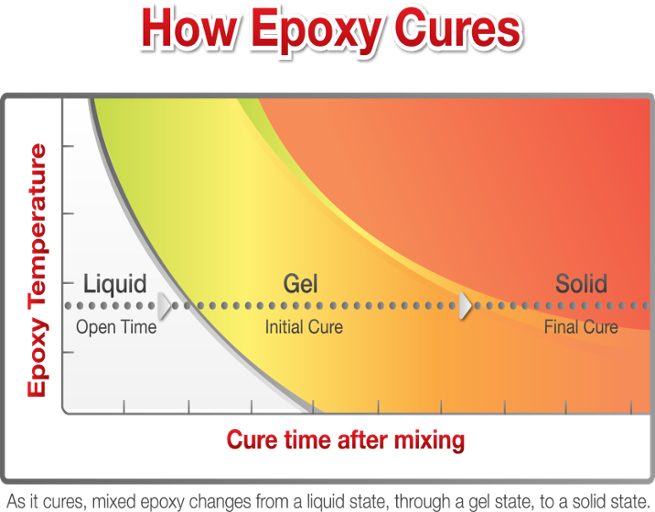

When it comes to curing epoxy, nothing is more important than a constant and uniform heat distribution. With a proper cure, you ensure the integrity and strength of your product. When epoxies are properly cured, they will become solid.

Temperature Influence in Epoxy Curing

The picture below is a good example of how epoxy cures depending on heat and time.

An uneven cure of epoxy can have several negative consequences, including:

- Discoloration/Yellowing

- Color Variation

- Blushing

- Uneven Gloss

- Poor Inter-Coat Adhesion

9 Things to consider in an Epoxy Heating/Curing Solution

- Even Heat: Prevent uneven gloss and poor inter-coat adhesion by finding a solution that evenly heats over the entire surface area.

- Hold the Temperature: Find a heating solution that will maintain the proper application temperature. The warmer the resin and hardener, the lower the viscosity.

- Meet Your Needs: Find a customizable heating solution that will properly fit the size and shape of your application to maintain maximum control. A cool epoxy is more difficult to meter and combine with the resin and hardener.

- High Quality: Ensure less maintenance downtime by finding a heating product with a track record of performance.

- Viscosity: Ensure that the epoxy resin and hardener will flow through dispensing pumps easily by maintaining the appropriate heat.

- Maintain the Mix: Ensure more cross-linking by warming the materials while mixing to initiate a better chemical reaction.

- No Air: Prevent air bubble entrapment and safeguard the strength and effectiveness of the epoxy by having the right heating solution.

- Keep it Clean: Prevent contamination by not using Kerosene or propane heaters since they can inhibit the cure as well as contaminate epoxy surfaces.

- Stay Solid: Prevent under-curing, as it can cause delaminations and product failures by finding an evenly heated and temperature-controlled solution.

Powerblanket Curing Solutions

It’s obvious that temperature control plays a huge role in epoxy curing. Staying in charge of the influence that temperature has on the curing process is the difference between a successful cure or wasted time and material.

Powerblanket supplies the best epoxy adhesive and resin temperature equipment on the market. You can find more about epoxy curing solutions here.

Frequently Asked Questions

What happens when epoxy is heated?

When epoxy is heated, the chemical reaction speeds up, enhancing the curing process by increasing the temperature of the epoxy through both ambient heat and the exothermic reaction generated during curing.

Will heating epoxy cure it faster?

Yes, applying heat to epoxy can significantly reduce curing time, as most two-component epoxy systems will cure faster with added heat compared to curing at room temperature.

How do you warm up epoxy resin?

To warm up epoxy resin, place it in a warm water bath for about 15 minutes, ensuring it is used promptly after mixing to prevent premature curing.

Will heat soften cured epoxy?

Yes, applying heat beyond the epoxy's softening point can soften cured epoxy, allowing for adjustments or removal if necessary.

Cure your epoxy resins faster and easier than ever before with Powerblanket.