Cold Weather Concreting

Imagine arriving at the job to find a fresh layer of ice and snow on your pour site. The weather forecast shows continual sub-freezing temperatures, and you are worried about getting the concrete stage done so your crew can keep the project on schedule. Even if you manage to successfully pour your slab, what will the end result be? It will take forever to cure, or not finish curing at all. The result may be a fragile, partially cured piece of concrete, riddled with defects from thermal stress.

It’s no secret that curing concrete in cold weather is a tricky endeavor. Mother nature can catch even the best trained crew off guard during the winter, and cause costly construction delays.

Conventional Concrete Warming Products

To avoid completely shutting down work during the winter, some construction crews turn to conventional concrete warming products and practices.

Insulation

Concrete hydration is an exothermic process and does create some heat. This heat can be trapped (to some degree) with the use of insulating blankets or straw. However, when pouring concrete in cold weather, providing thermal insulation is only half the battle. Insulation alone does not create heat and will not provide enough surface contact to effectively trap heat on really cold days.

Forced Air Heaters

Some crews build temporary enclosures over their pour site and use heaters to force hot air over the slab. This radiant heating method spends more time and energy heating the air around the concrete instead of heating the concrete itself. During the winter, a lot of heat can also be lost through the bottom layer of the slab into the sub-grade. This uneven heat will cause the top layer of concrete to cure much faster than the bottom, leading to shrinkage and a weak cure.

Calcium Chloride

Using accelerators, like calcium chloride, in your concrete mix is a two edged sword. It can certainly reduce winter cure times, but it also contributes to a variety of defects. Calcium chloride can cause corrosion of steel reinforcements in your concrete. It can also increase volume shrinkage, scaling, efflorescence, and discoloration.

Electric Concrete Curing Blankets

When you combine heating power with the protection of insulation, a world of possibilities opens on your job site. Not all blankets are created equal, and Powerblanket’s concrete blankets are a cut above the rest. We specialize in total temperature control that gets you and your crew back to work.

How Powerblanket Products Work

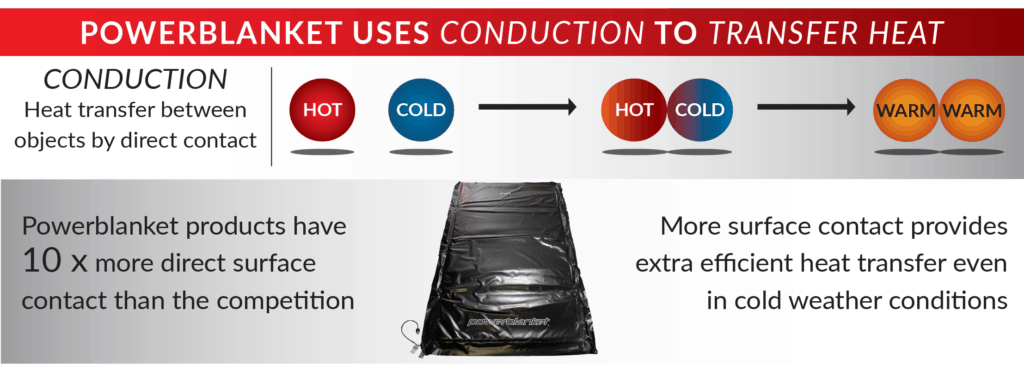

Heat Transfer Through Conduction

Powerblanket saves you time, energy, and money by putting the heat precisely where it is needed. By simply placing down our concrete curing blankets, you are harnessing the power of conduction and heating your concrete directly. Fresh concrete must stay above 50°F for 48 hours in order to hydrate and cure to a strong finish. Direct conductive heat gives you peace of mind and takes the hassle out of curing temperature maintenance.

More Surface Area Contact

During wet, windy, and cold winter conditions, surface contact between your heat source and your concrete is critical. Our concrete curing blankets have 10x more surface contact than other blankets. More surface contact means even and controlled heating so your concrete cures uniformly.

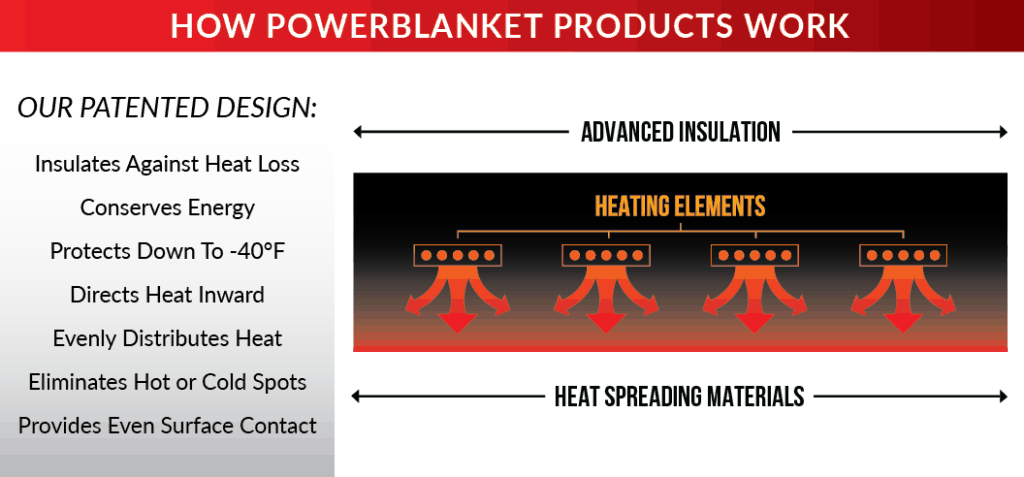

Weather Proof Insulation

Simply put, thermal insulation reduces the transfer of heat between objects. Our heavy duty, weather-proof insulation provides a protective barrier from the elements and reduces heat loss. Our insulation doesn’t just trap the exothermic heat generated by the hydration process. We combine insulation with efficient heating elements to direct heat downward right into your concrete slab instead of losing it to the winter air.

Powerblanket Benefits

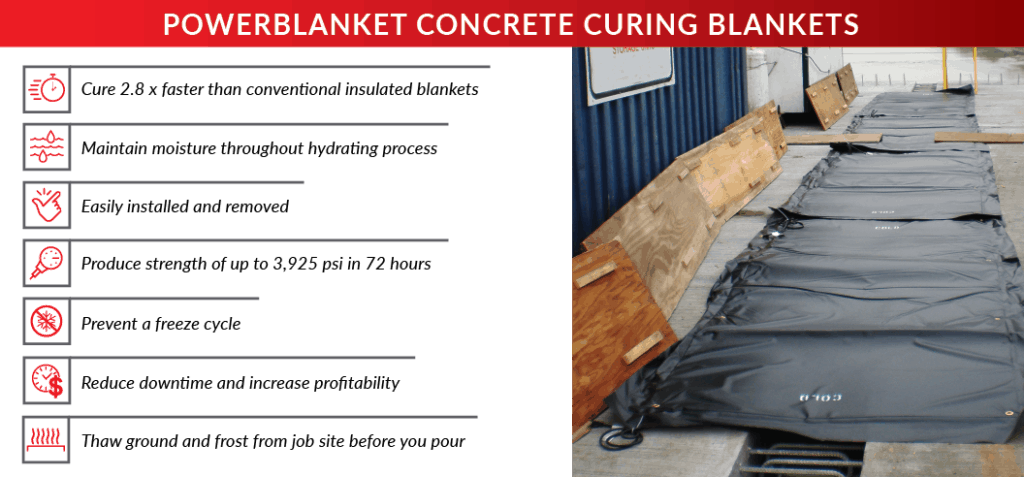

Faster Cure

Winter conditions notoriously slow down or sometimes stop concrete from curing. Our concrete curing blankets cure 2.8x faster than conventional insulated blankets. Faster cure times allow your crew to move on to the next building stage and help your project finish on schedule.

Maintain Moisture During Hydrating Process

Moisture loss during hydration weakens the cure of your concrete. Our blankets protect your slab from the elements during the hydration process and allow the necessary chemical reactions to finish.

Easy to Install and Remove

Forget bulky heaters, finicky straw, and time consuming enclosures. Simply place our concrete blankets down and let them do the work for you. They are easy to remove and store for future needs so they can continue to save you time and money down the road.

Stronger Cure

Powerblanket ensures your concrete is durable and built to last. By using our concrete curing blankets you can produce a 3,925 psi rating in just 72 hours.

Prevent a Freeze Cycle

Freezing during the early stages of curing can greatly reduce the integrity of the concrete by as much as 40%. Powerblanket heated concrete blankets not only generate and evenly distribute heat but retain that heat over longer periods of time allowing the concrete to avoid damaging freeze-thaw cycles during curing.

Reduce Downtime and Increase Profits

Fewer tasks hold up a construction site like concrete troubles. Save yourself from expensive repairs and re-pours by having the right temperature control products on hand before disaster strikes. Curing your concrete quickly and strongly allows your crew to meet deadlines and move onto the next building stage.

Thaw Ground and Warm Sub-grade

Our concrete blankets can serve multiple purposes on your site. By placing them down before a pour, you can thaw frozen ground and heat your sub-grade. This not only protects your concrete from losing heat into the ground it also reduces thermal cracking that occurs when warm concrete is poured directly onto a frigid surface.

ACI Certified

We are dedicated to providing high quality and reliable concrete solutions and all of our concrete blankets are cold weather certified by the American Concrete Institute.

Powerblanket Guarantee

With total temperature control from Powerblanket, there is no off season. We keep your crew working and your job site productive all winter long. Contact us to find the right concrete solution for your needs at 866.945.4203 or [email protected].

Cure your concrete faster and better in cold weather conditions with Powerblanket.