It’s time to answer the age-old question: why does road construction take so dang long to complete? Does it really take months to rip up a road, drop some fresh asphalt, and paint a few lines? The answer is more complex than you think.

Road Construction: The Never Ending Story

No patch of pavement escapes road construction. Every stretch of road in the world has a countdown timer to when it needs to be repaired or replaced. Drivers hate road construction due to the length of the construction process, delaying travelers and slowing the flow of goods between cities.

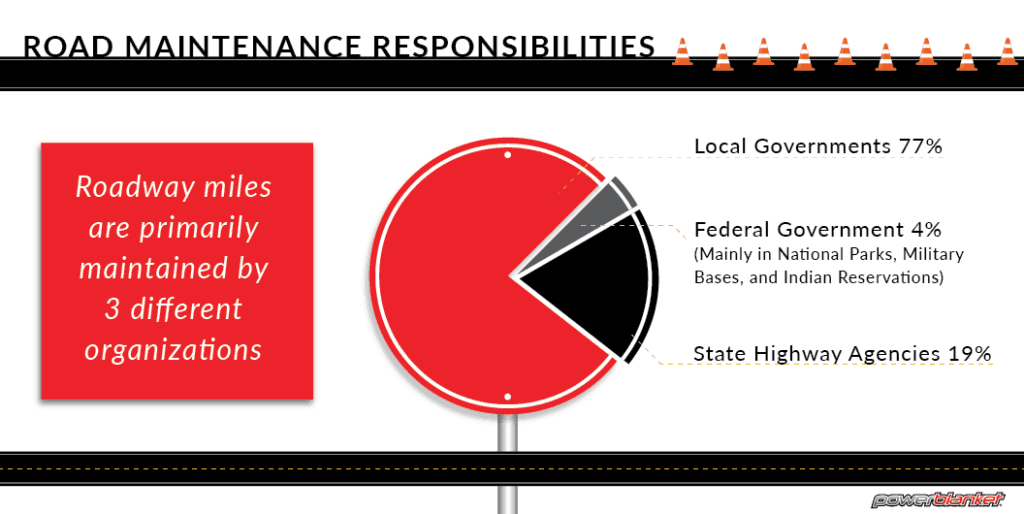

Because roads have a short lifespan, road construction is happening all the time, everywhere. The American Road and Transportation Builders Association says that as of 2017, there are 4.18 million miles of roadway in the United States, including Alaska and Hawaii. Much of those are in drastic need of repair, with nearly 20 percent of all major highways needing “repaving or even more substantive repairs.”

Expensive Asphalt

The costs for repairing any mile of roadway varies by location and available resources. Midwest Industries, a company that plays a vital role in road construction, estimates that road repair per mile starts at a low of $2 million:

Constructing a two-lane, undivided road in a rural locale will set you back somewhere between $2 and $3 million per mile — in urban areas, that number jumps to between $3 and $5 million. In a rural area, you can essentially build a road wherever you please (local zoning and property laws abiding), but in a city, you have to avoid the surrounding firmament and infrastructure and comply with strict construction codes.

…If you want wider roads, the costs understandably go up: for the production of a 4-lane highway, the cost per mile will run between $4 and $6 million in rural or suburban areas, and between $8 to $10 million in urban areas. For a 6 lane interstate highway, you’re looking at $7 million for a rural mile of road, and $11 million-plus in an urban locale.

Obviously, construction costs can easily overrun when you account for other factors like weather, available building resources, etc.

What’s in a Road?

It takes a lot of money to build a road. It also takes a lot of time. The best reason to explain why road construction takes so long is because of all the considerations one must take into account to build the road. These can include:

- Where the road will be built

- Rural areas are much cheaper to build roads and highways than urban or inner city locations. Rural areas also often require less legal hurdles to jump through when obtaining land to build the road.

- Grading and filling gives the road a smooth, flat surface to be built on. Digging out a hillside or filling in a ravine will slow work until the grades and fills are finished and deemed safe to build on.

- What the road will be made of

- Most roads are paved asphalt, but highways can be constructed out of concrete. Both make great roadways depending on the type of road best suited to that particular environment.

- If utilities need to be placed under the roadway

- If sewer pipes or electrical lines need to be replaced, it’s best to do so while the road above it is being torn up for repairs. Construction of the road can easily be delayed to make room in the schedule for utility companies to have access underneath where the road will eventually go.

- How much traffic crews need to divert during construction

- Building a new road where one didn’t exist before allows for construction crews to build at their own pace, unhindered by local traffic.

- When roads are being repaired or replaced, crews must account for traffic. Detours need to be planned and mapped out. Lanes need to be adjusted, and signage for those changes need to be placed to let drivers know about the construction.

- Repairing a stretch of road next to one still being used by traffic limits the amount of space crews have to work with. This can easily extend the project timeline for the sake of inconveniencing local traffic as little as possible.

- Inspections

- Before any shovels dig into the ground, inspections must be made to assure taxpayers that the road will not have negative effects on the environment. Builders have to consider how groundwater, animal life, drainage, noise levels, and the proximity to schools and homes will have an impact.

- The base layer of the road, which is the gravel aggregate foundation that the road layers will rest on, needs to be just right in order to further construction to happen. If there is an issue with the quality of the base material (for example, the base material has settled too much and has become porous), it must be either replaced or recompacted before moving forward.

- Concrete strength should be measured as it cures to determine if it can handle the weight of a hillside or potentially millions of vehicles a year. This is especially important when building bridges, retention walls and tunnels.

- Weather

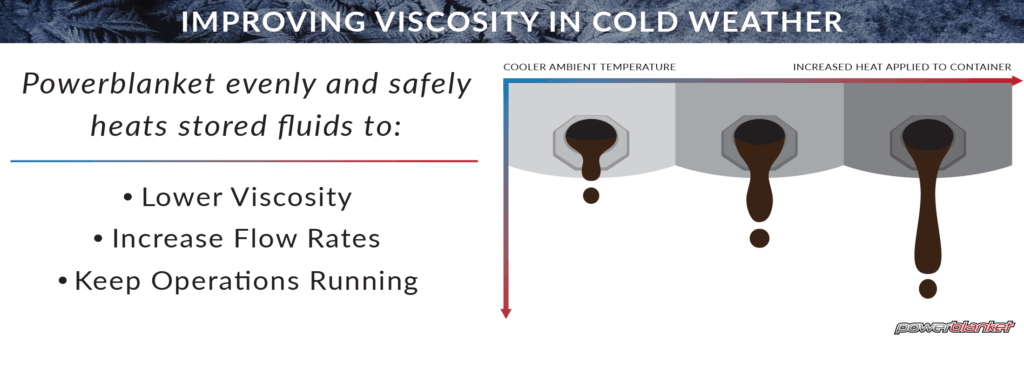

- Good luck paving asphalt in the freezing cold. When temperatures drop below optimum levels and begin affecting the road project (via thickening chemicals, frozen ground, exposed pipes and valves), you need to get in control of those temperatures. Products such as heating blankets keep temperature-sensitive material warm, cure concrete faster, and prevents ice buildup on construction equipment.

Just from this short list of considerations when building roads, you can see why they take so long to construct. Nothing can be overlooked. Your safety depends on it.

Road Construction: It Happens, So Be Prepared

There is a lot that goes into road construction. Delays can be costly for involved businesses and irritating to drivers.

One of the most easily mitigated issues when building a road is temperature control. Make sure that you’re using the best heating equipment available to keep your project on schedule and prevent costs from overrunning.

Powerblanket offers the highest quality heating blankets in the world. Whether building a road from scratch or patching a hole in the asphalt, Powerblanket will make sure cold temperatures don’t impact your project. Call 844.245.6604 or email [email protected] for more information.

Frequently Asked Questions

Why does road construction take so long in the USA?

Road construction in the USA often takes a long time due to complex planning, necessary underground utility work, and the need to complete certain project phases in sequence, all while ensuring safety and compliance with regulations.

How long does it take to construct a road?

The time it takes to construct a road can range from a few weeks to several years, depending on the project's size and complexity, with significant time dedicated to earthwork and establishing a solid foundation.

Why does it take so long to repair a road?

Road repairs can be prolonged due to limited resources, prioritization of projects, adverse weather conditions, and the time required for inspections and approvals.

What causes road construction delays?

Delays in road construction are often caused by factors such as weather conditions, equipment failures, labor shortages, and the need for accurate data and project coordination.

Cure your concrete faster and better in cold weather conditions with Powerblanket.