What’s more beautiful than fresh, untouched snow in the morning light? A clear walkway, you didn’t have to shovel or salt. Fresh snow comes with a cost: shoveling, slippery stairs, ice, repeat. Many home and business owners would love a quick winter fix. Powerblanket’s heated walkway mats can make your winter snow maintenance a breeze.

THE UNWANTED SIDE EFFECTS OF ROCK SALT

While rock salt may be the most economical solution for snow and ice accumulation, it can cause problems for pavement, concrete, and vegetation. Rock salt can seep into the porous surface of your concrete and make a home inside, making the concrete more prone to deterioration. Salt crystals inside of concrete also draw water toward them, increasing the saturation potential of concrete by 9%.

Depending on the thaw/freeze cycle of your winter, your concrete could experience some significant damage. Asphalt surfaces, brick and stone used in home walkways, and landscaping also suffer from the salt/water infiltration and freeze/thaw cycles, though not quite as much as concrete. Since plants cannot “sweat off” salts like animals, they have to shed leaves/twigs. Salt also reduces soil quality and attracts water, which makes it harder for root systems to pull the water into the plant.

With heated walkway mats, these environmental side effects are completely avoided. Save your concrete, pavement, and vegetation.

SNOW MELTING MATS

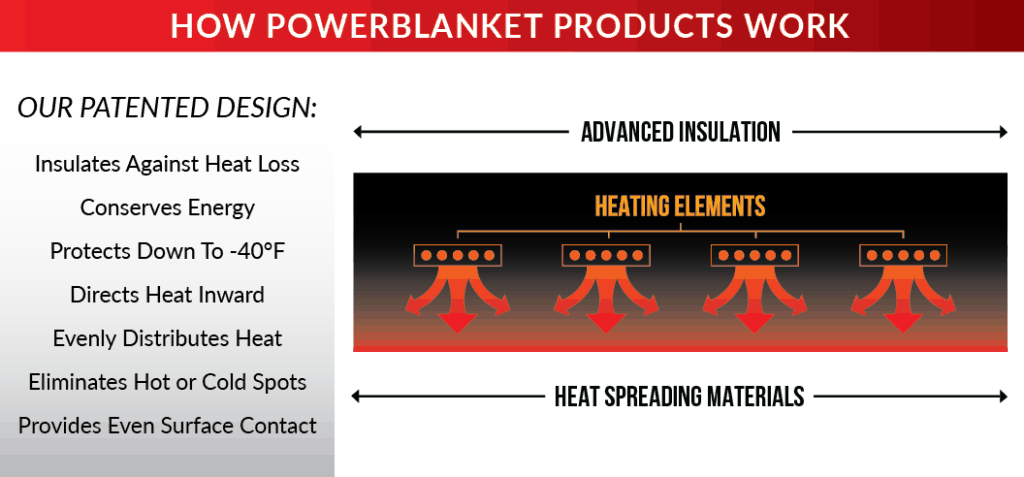

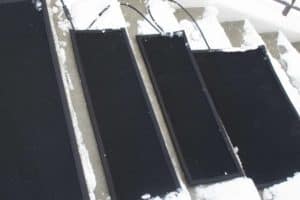

Ground-thawing heated snow mats are ideal for both residential and industrial applications. Using Powerblanket’s radiant heat technology, our ground-thawing blankets can be used to clear walkways of ice and snow.

Ground-thawing heated snow mats are ideal for both residential and industrial applications. Using Powerblanket’s radiant heat technology, our ground-thawing blankets can be used to clear walkways of ice and snow.

RESIDENTIAL MELTING MATS

Keeping snow and ice clear from walkways and stairs around the home is important in protecting your family from injury. Because other methods to melt snow can be time-consuming and cause damage to your landscaping, consider using heated mats. Melting mats for your home are a simple solution to prevent injury without the hassle.

Because they are designed to be left out all winter, residential mats can be easily installed and left to do their job. They are reliable and keep paths clear from snow and ice even in harsh winter storms. They are also environmentally safe and don’t contain harsh chemicals, giving you peace of mind, especially with kids and pets around the home. This is important for the protection of your plants as well. Whether you need a walkway, stair or door mat, Powerblanket has what you need in a variety of sizes to get you through a snowy winter.

INDUSTRIAL MELTING MATS

More than one million Americans suffer from injuries related to slips and falls each year. From hospitals and nursing homes to large construction sites or small restaurants, any business based in cold climates is forced to think about snow and ice removal. Slippery conditions have the potential to cause many hazards that delay productivity, increase costs, and cause accidents. Protecting both your employees and customers from preventable falls doesn’t have to be time-consuming or expensive. You can lower your liability and prevent injury with the use of ground-thawing mats.

These mats are customizable, so you can be sure that you are covering all areas that get a lot of foot traffic around your business. They also include connecting accessories so you can position the mats to fit the layout required for your needs. You can connect multiple mats and use a Beacon for more precise control. The mats melt about two inches of snow per hour when operating, making it easy to keep your walkways clear. Other benefits of using melting mats for your business include:

- Save time and money

- Durable and long-lasting

- More convenient than shoveling snow

- Peace of mind warranty

- Reliable even in the worst conditions

- The ONLY snow-melting mat made in the USA

Outdoor ground-thawing and snow-melting mats keep stairs, doorways, sidewalks, driveways, ramps, walkways, and alleyways safe and secure from slip-and-fall accidents. Use these mats to save your concrete, pavement, and vegetation and prevent hazards created by icy winter weather.

Frequently Asked Questions

Do heated walkway mats work?

Yes, heated walkway mats are effective at melting snow and ice quickly, providing a safe, slip-free surface without the need for shoveling or harmful chemicals, making them a reliable solution for winter safety.

How much electricity do heated walkway mats use?

The electricity usage of heated walkway mats varies by size, but they are generally cost-effective, with operational costs being a small price to pay for the convenience and safety they provide during snowy conditions.

Are heated driveway mats worth it?

Heated driveway mats are worth the investment as they save time, reduce the risk of slips and falls, and help preserve the integrity of your driveway while being environmentally friendly compared to traditional deicing methods.

How do you heat a walkway?

Walkways can be heated using electric radiant snow melting mats, which are easy to install and provide an efficient solution for keeping paths clear of snow and ice throughout the winter.

Keep your steps, doorways and walkways safe this winter with our ground-thawing and snow-melting blankets.