Need Custom Heating for Your Equipment? Answer These Questions

Do you need custom heating for a specific and unique application? Although there are various standardized heating solutions available, to determine the right solution, either standard or custom, a few initial questions need to be understood. The first of the discovery questions is to identify the desired result of the application which is generally one or a combination of the following:

- Freeze Protection: Generally to protect from the elements or cold climate

- Temperature Maintenance: Maintain a specific, constant and optimal temperature

- Added heat or Increase Temperature: Add heat and Increase temperature higher from starting point

For example, a pipe heating application may require higher energy/wattage to thaw a frozen pipe and then settle to a moderate power/wattage for continual freeze protection and flow control long term.

An epoxy/composite curing application may require pre-heating at higher temperatures prior to the epoxy being applied and then maintained at a higher temperature for optimal curing.

Begin with These Steps

- Gather as much information as possible using the Custom Application Questionnaire. Be thorough.

- The dimension needs to be as built, not a CAD drawing . ALL dimensions must be submitted to the custom team for quote.

- Once quote is accepted and PO is sent, engineering will begin.

- Custom products will normally be completed within two weeks.

Custom Application Questionnaire

Once we understand the problem, these types of questions reveal the best solution:

- Which of these best describes the system requiring Cooling: drum/bucket, tote, tank, gas cylinder, pipe, flat surface (vertical or horizontal?), other?

- Can you provide drawings and/or photos?

- What are the critical dimensions of the system?

- What material is the container or surface made of (i.e. tank wall, drum wall)? How thick?

- What is the substance being Cooled (i.e. water, oil, pipe contents, concrete, frozen ground)?

- Is this a flowing system? If so, what is the flow rate (include units, gpm, cfm, etc.)?

- What is the expected ambient temperature (include units, °F, °C)?

- What is the maximum expected wind velocity (include units, mpg, km/h, etc.)?

- Are there other environmental conditions that may be relevant?

- What is the beginning temperature of the substance or contents (include units, °F, °C)?

- What is the desired final temperature of the substance or contents (include units, °F, °C)?

- What temperature range is acceptable?

- Are there upper or lower temperatures where the substance or contents will be damaged?

- Is there a time frame requirement for the initial cool down?

- What power source is preferred (120, 208, 240, DC)?

- How far away is the power source (cord length)?

- Do you require UL/CSA certified products?

- Is your location considered hazardous (Class I Division 2)?

- How many units do you need now and in the future?

- What is the required delivery date?

Custom Heating Case Study

Powerblanket completed a project for a large chemical company to solve freeze protection problems. The company stores a chemical solution in large 4,000 to 8,000 gallon stainless steel tanks. Their customers live in various climates throughout North America. This solution is water based and freezes at roughly 32°F. This company needed freeze protection and to maintain regular temperatures between 40°F -70°F.

The question became, “How do we provide a ‘one size fit all’ customized solution for various climates?” Powerblanket created a modular custom design, adjustable by region and tank size, that came in two pieces.

Powerblanket engineers calculated the amount of heat and insulation required to combat freezing temperatures and wind chill to maintain optimal temperatures in these various climates. What appeared to be a complicated application turned into a simple and effective custom solution.

So many industries need heating solutions, and not just during the cold months either. Epoxy curing, chemical storage, viscosity maintenance, food preparations, concrete curing, and much more all benefit from innovative temperature regulation year round.

Custom Heating vs. Ready to Ship Products

Powerblanket manufactures an extensive line of ready-to-ship products designed and engineered for a myriad of purposes. For example, if you store temperature-sensitive materials in drums, barrels, or totes, then our ready-to-ship barrel and drum heaters or tote heaters will accommodate your heating needs perfectly. If you store DEF, then take a look at our DEF heaters. If you have palletized product you need to keep warm, check out our Hot Box.

Along with all these great product offerings, however, one of Powerblanket’s greatest contributions to the industries we serve is custom process heating solution for any project under the sun.

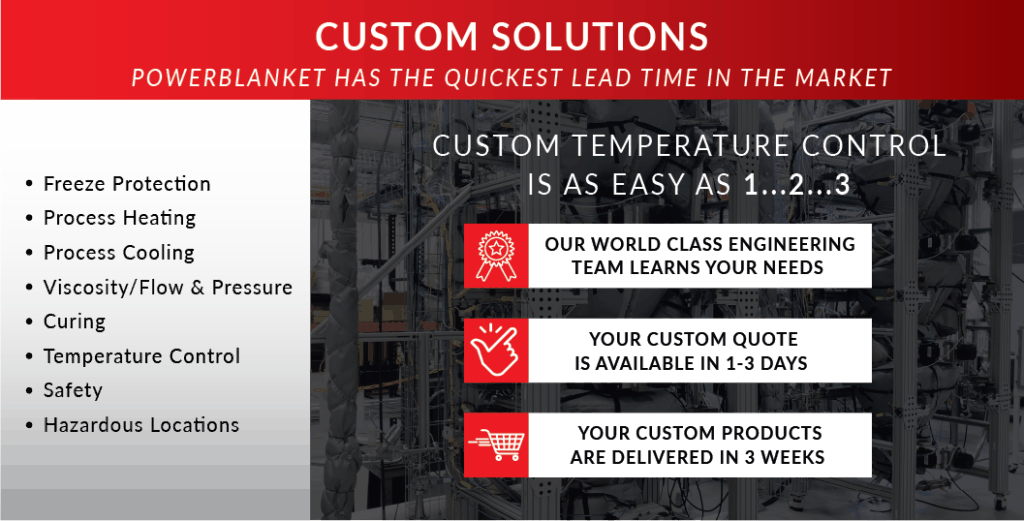

Often “custom” connotes extended lead times and a lot of money. With some manufacturers, that may be true, but Powerblanket’s customization process is fluid and effective. We turn around a custom product in a reasonable window. Expect to be wowed.

Whether you need a heating solution for a large or oddly shaped propane tank, truck-mounted water cylinders, valves, manifolds, instrumentation, large scale epoxy curing, or any other specific application, Powerblanket is ready to help.

Custom Heating Solutions from Powerblanket

- A reasonable window for completion

- The ability to answer varying levels of customization

- Certification to universal safety standards

- Easy installation and use

Powerblanket engineers solve every kind of temperature problem from simple to very complex. Our expertise guarantees satisfied customers in a very short turnaround time. Need custom heating for these vessels?

- Drums / Barrels / Pails

- Totes to include Diesel Exhaust Fluid Totes

- Gas Cylinders to include Propane and Specialty Gases

- Specialty Tanks to include Frac Tanks

- Water Transfer Trucks

- Water Storage Tanks

- Hydraulic Fluid Tanks

- Vac Trucks

Industries Powerblanket Serves

With Powerblanket, equipment lasts longer, projects stay on track, and fluids flow smoothly. Use Powerblanket technology year round to achieve total temperature control. Some of the various industries we serve include:

- Oil/Gas

- Railroad

- Sprayfoam

- Coatings

- Chemical

- Piping

- Valves

- Instrumentation

- Food Processing

- Composites

- Construction

- Precast

- Roofing

- Industrial

- Manufacturing

- Specialty Gases

- Agriculture

- Dairy

- Mining

- Concrete

- Public Works

- Excavation

- Water Purification

- Government & DOD

- Fertilizer

- Brewing

- Fermentation

- Welding

- Diesel Exhaust Fluid

Frequently Asked Questions

What is a custom heating solution?

A custom heating solution is a tailored system designed to meet specific technical and operational requirements, offering precise temperature control and energy efficiency for unique industrial applications.

How do you design a custom heating solution?

Designing a custom heating solution involves understanding the specific application needs, gathering detailed information through a questionnaire, and engineering a system that meets precise temperature and operational requirements.

Why would you need a custom heating solution?

You would need a custom heating solution to address unique heating challenges that standard products cannot meet, ensuring optimal performance and efficiency for specific industrial applications.

What industries benefit from custom heating solutions?

Industries such as oil and gas, food processing, chemical storage, and construction benefit from custom heating solutions due to their need for precise temperature control and specialized heating requirements.

How long does it take to create a custom heating solution?

Creating a custom heating solution typically takes a reasonable window of about two weeks from the acceptance of a quote to completion, depending on the complexity of the project.

When you need a custom temperature control solution, Powerblanket is the company to call. With over 30 years of experience, we can solve any heating dilemma you have.