When it comes to knowing when the best time of year is to conduct construction projects, the weather is god. Cold and wet months are nearly impossible to build homes, dig pipes, and pave roads in. What time of the year is best for construction season?

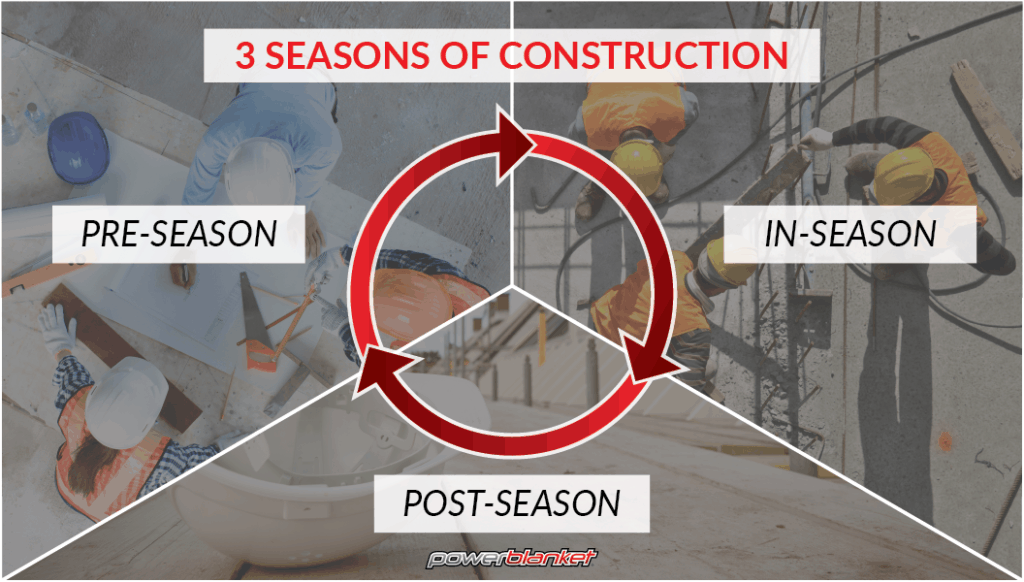

The Three Seasons of Construction Work

Work can only be completed if the weather permits it. This is why it’s critical for every construction company to be ready to work as soon as the sun begins to shine. Knowing when to work is best understood when you look at the year as three parts: pre-season, in-season, and post-season.

Pre-season

This part of the year is from January-March, when construction managers need to take into account everything they will need for the upcoming work season. According to Tim Murchison, owner of California-based Murchison Builders, managers need to “maximize the best interest of the project including cost schedule, quality, safety and the owners goals.” Doing so will ensure that each of your construction project needs will be met, including:

Scheduling

Time spent not building something is time spent not making money. Make sure you have enough projects lined up for the work season so there’s no gap in company revenue. If you have any openings between big jobs, try to fill them with smaller opportunities to make some quick cash.

Budgeting

Budgeting is never an after-the-fact step in a business plan. It happens before a single dollar is spent or earned. How much money does your business need to stay in business? What projects are you going to take on in order to keep your company afloat, and what funding measures will you need to take to ensure you can fulfill next year’s projects?

Looking at your budget can also help you see when financing options need to be considered. Got a project next year that requires a massive equipment purchase? A loan might be the best way to obtain that equipment before other companies are able to buy it at the start of construction season.

Equipment and Material Purchases

Once you know how much you can spend on equipment and construction materials, check to see if the off season is the best time to buy.

The cost of equipment every year seems to only increase. Whether it’s renting a backhoe or buying a new bulldozer, prices tend to go up overall. This is especially true during the start of construction season, when demand for equipment and materials is high. Get ahead of the crowd by ordering early.

Hiring and Training

In 2014, Golden Rule Lawn Care was preparing to open a new branch of the business in Redmond, Washington. Golden Rule’s main focus is in moss removal and grass seeding, which can only be done when the heaviest part of the rainy season in western Washington had ended. Owner David Hancock made sure to be ahead of the weather by hiring employees in February and trained them in March, well before work orders started coming in later in the spring. Hancock also purchased the needed thatching equipment, seed, a truck and cargo trailer, and located a place to store the company equipment every night. By the time the rainy season ended in early April, Golden Rule was ready to work.

Make sure to do as much hiring and employee training in the off season as possible. Hiring ahead of time allows you to survey the best employee candidates, as opposed to taking anyone you can find off the street on your way to a job. Employees who are taken on early and trained in specific skill sets for the job tend to have a high retention rate.

Training is also important to take care of before construction projects begin. Off season training allows for mistakes that can be corrected in an educational setting, but can’t be fixed once on the job.

In-Season

In most states, the best time of the year to complete construction work is from April through October. The weather tends to be drier and the ground warmer than in the pre-season or post-season. Utilizing the pre-season tips above will extend your summer construction season by weeks, possibly even a month or two, bringing in extra income and boosting your reputation as an effective, dependable contractor.

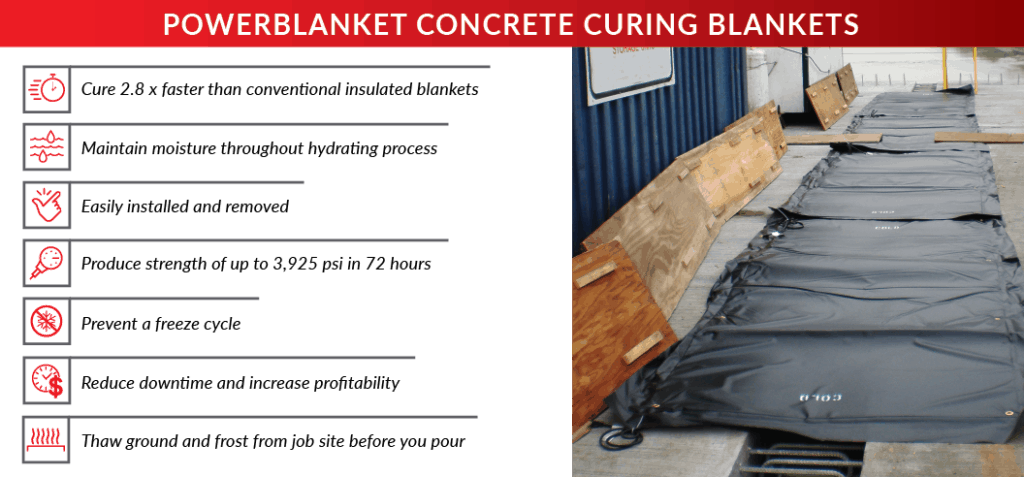

It’s important to make as much progress as you can while the weather is cooperating with your schedule. Sometimes, night construction is necessary to getting a job done on time. Not only does working at night generally mean less traffic to deal with, but it also is cooler. In Las Vegas, for example, road construction often happens at night. With temperatures dropping into the 80s and 90s, this is a prime time to get things done before the heat of the day returns. Concrete cures better and asphalt dries faster, and fewer cars on the road lead to fewer traffic-related safety incidents.

Another element of making the most out of construction season is to be timely. Your packed schedule doesn’t allow for sleeping in or long lunches, so make sure to use your time every day as effective as possible. The same goes for your employees. Make sure their needs are met so they don’t have to leave the job site often.

Regardless of what time of day or what day of the year you’re working, the important part is to be prepared to do all the work you can.

Post-Season

With your main source of income coming to a close after the construction season, it’s time to reduce your operations to deal with the lack of work opportunities. Scaling down lowers your costs of doing business, allowing you to gain more profits from smaller jobs during the winter months.

Winter work is a great way to maintain a flow of income while waiting for the big money-maker jobs to come back in the summer. Construction experts at Procure recommend giving yourself a variety of options, which include:

- renovating houses

- building cabinetry

- installing carpet in retail spaces

- plowing snow

- home repair

- project consulting and planning

There are plenty of opportunities to work even when it seems like all local construction has come to a standstill.

The post-season can also be wisely spent as a review period. How efficient were your operations this past work season? Looking back, do you see any costs or equipment that was unnecessary? What did you do or not do that made you less prepared to complete projects during the summer? Answering these questions will help you and your business be ready to launch into the pre-season of construction work.

One of the most important things you can take care of during the post-season is you. Take a vacation, or at least devote some of your time to making sure you have a healthy mind and body that can deal with the stresses of running a business. Being mentally fit will do wonders for you, your employees and your customers during the main construction season.

Construction Year-round

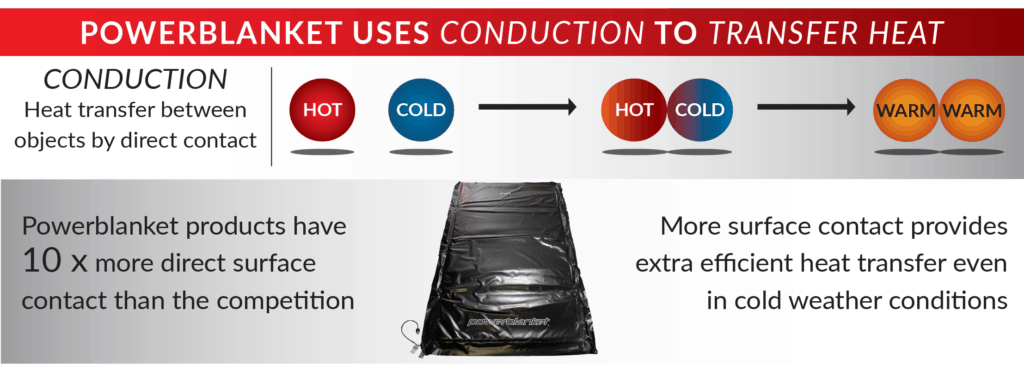

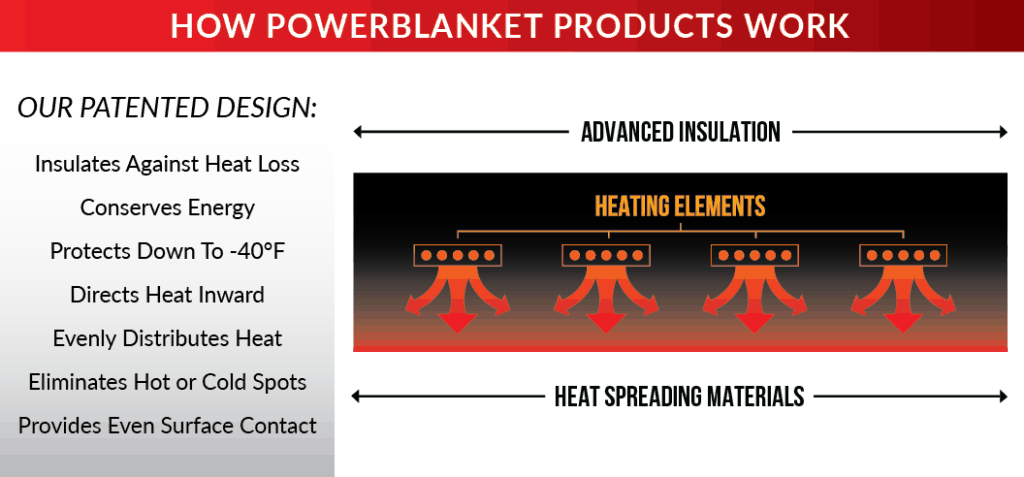

Working as a contractor gives you the flexibility to run a business like no other. Unfortunately, you’re still subject to weather conditions that can put a literal freeze on your work projects. That’s why Powerblanket is here to help you make the most of your construction season no matter how cold it is. From concrete curing blankets and ground thawing covers to snow melting mats and spray foam heaters, Powerblanket puts you back in control over cold temperatures. Call us at 866.945.4203 or email [email protected] to learn more.

Frequently Asked Questions

What is the construction season?*

Construction season typically spans from April to October, especially in northern regions, where favorable weather conditions allow for efficient and safe project execution.

What season is best for construction?

The best season for construction is usually from May through September, as these months offer optimal weather for completing projects quickly and efficiently.

What is the busiest season for construction?

Summer is the busiest season for construction due to long days and dry conditions, which are ideal for projects like roofing and paving, though heat management is crucial for worker safety.

What months are slow for construction?

Construction tends to slow down or halt during the winter months, starting in December, due to adverse weather conditions that impede outdoor work.

Don't let the cold weather stop you, and keep your construction project on schedule. Powerblanket has you covered.