Dropping temperatures can slow projects of all kinds. Many industries experience low productivity and profits during the winter months. However, the railroad industry is one that must continue the same productivity year round—regardless of weather.

Winter’s Impact on the Railroad

Railroads are an important industry for the American economy (and for many economies worldwide). When you consider how much freight passes through locomotives every year, you can account for a significant amount of the goods and supplies that many companies rely on. The railroad industry simply can’t afford winter downtime.

Cold weather can stop many different types of fair-weather operations, but the railroad isn’t one of them; there is too much at stake. Yet, despite the continuity demanded of our railways, cold temperatures can drastically affect the materials and equipment needed to keep trains moving.

Freezing conditions cause a wide variety of operational problems for the railroad industry. Let’s take a closer look at a few of these winter woes.

Frozen Track Switches

As ice and snow buildup along the track, switches become points of vulnerability. A frozen switch will bring the railroad to a halt or can catastrophically send trains in the wrong direction entirely. Railroad companies most commonly use electric and gas powered heaters to melt, and drive away ice and snow from these switches.

Reduced Gas Pressure

The gas powered heating systems mentioned above, rely upon on-site gas storage cylinders filled with either propane or natural gas. When temperatures drop below freezing, the gas pressure within the tanks also falls. A drop in pressure will restrict gas flow to such a degree that you can no longer reliably power your critical heaters.

Ice Blockages and Build-up

Wintertime ice build up can happen in a number of different ways. Burst pipes, repeated freeze-thaw cycles, freezing rain, and ice storms can cause ice to build up on any and all vertical or horizontal surfaces. Railroad sensors, detectors, and other pieces of equipment need to remain unobstructed at all times. Wayside, defect, and drag detectors placed along the track can discover problems with the train as it passes overhead. Ice build up prevents these detectors from functioning and compromises safety along the entire track. Ice build up can also cause malfunctions for crossing gates, safety signals, and other pieces of equipment up and down the track.

Ground Heave

Subterranean frost can cause the ground to heave, swell, then sink as it freezes and thaws. For railroads, this can create a serious problem. Ground heave can dislodge and break apart sections of track, making them unusable until they are repaired. In some locations, because ground water can freeze several feet below the surface, these repairs produce a lot of costly downtime. Excavating, leveling, and grading frozen ground is extremely time consuming and difficult.

Unworkable Repair Materials

Rail companies use multiple methods to lubricate their tracks and wheels and prevent destructive friction. Some use wayside lubrication stations placed next to the track right before a curve or switch. These storage containers are activated when a train passes over a sensor, and then lubricant is sprayed over the wheels as they pass. Train cars can also be outfitted with on-board greasers that will trigger lubrication before entering a curve or switch. Some rail companies also use mobile greasing trucks, with lubricant storage mounted at the back, that can easily get around to apply lubrication or re-fill wayside grease storage.

Stored liquids become thicker and more viscous as temperatures drop. Storage drums, buckets, and tanks that produce an easy flow of grease during the summer months can become completely unusable during cold conditions. In general, highly viscous fluids are extremely difficult to pump, spray, spread and work with.

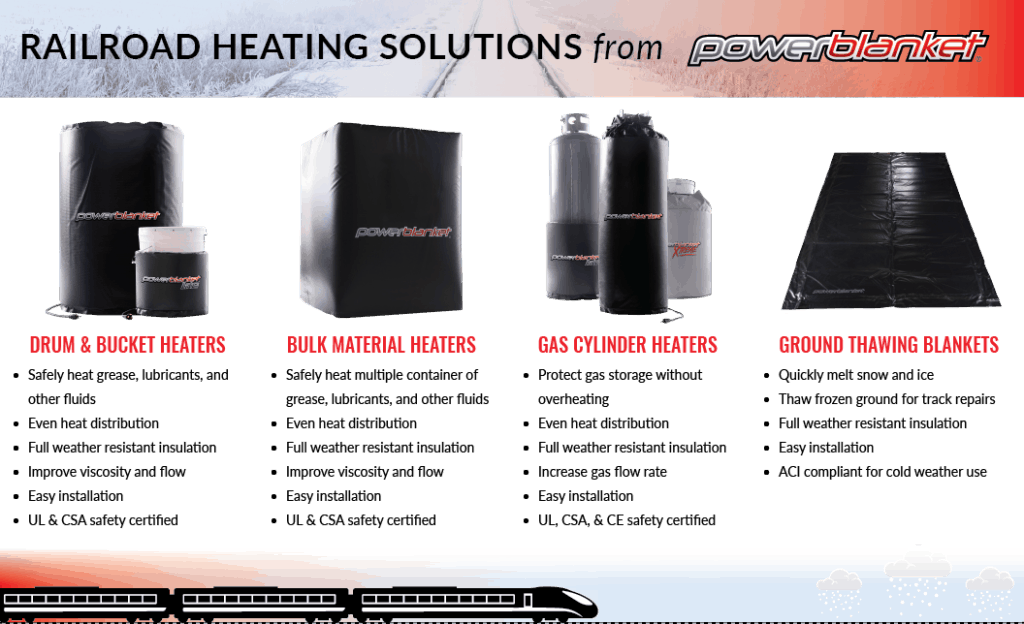

Powerblanket Railroad Heating Solutions

With the high demand to stay operational, how does the railroad industry solve this wide spectrum of winter issues? Thankfully Powerblanket specializes in innovative railroad heating solutions that save time and money, protect equipment, and keep cargo and passengers moving all winter long. Because keeping our railroads running, in turn keeps the economy running.

Gas Cylinder Heaters

Powerblanket keeps your gas powered switch heaters operating all winter long. Our gas cylinder heaters solve propane and natural gas flow problems even in the coldest of conditions. Our gas cylinder heaters are UL, CSA, & CE safety certified with additional hazardous location certifications available.

Drum & Bucket Heaters

Here at Powerblanket, we know that cold temperatures can make industrial fluids impossible to work with. Our drum and bucket heaters are the perfect solution for grease and lubricant viscosity issues. Safely and evenly heat railroad lubricant storage containers and restore them to workable temperatures.

Bulk Material Warmers

For multiple containers of varying shapes and sizes, our bulk material warmers are the perfect heating solution. Powerblanket hot boxes eliminate hot and cold spots and distribute heat evenly to all materials and equipment housed inside. Our bulk material warmers are easily portable and can provide heating during storage or transportation.

Ground Thawing Blankets

Powerblanket’s high heat ground thawing blankets provide deep penetrating heat to melt stubborn ice blockages and thaw frozen ground. Heavy duty, weather resistant insulation directs heat exactly were it is needed most and removes frozen obstacles all down the rail.

All in all we specialize in ensuring operational continuity and pride ourselves on solutions that get the railroad industry back to work, no matter what mother nature throws your way. Contact Powerblanket today to find the perfect railroad heating solutions for your needs at 855.977.9657 or [email protected].

Keep your propane tanks at the perfect pressure with Powerblanket.