Custom orders often have the stigma of being time-consuming and laborious. “How long is that going to take?” we ask ourselves. Well, in the case of Powerblanket custom process heating solutions, not long at all. Our innovative approach to custom heating doesn’t take as long as you might think.

Custom Heating Cases

Powerblanket works with many companies in a myriad of industries to supply custom heating solutions to a wide range of needs. So what does a custom order process look like when working with us? We’ll show you.

Enduraplas

Enduraplas specializes in all thing liquid management, whether that be storing, transporting, spraying or more. Their manufacturing process uses propane extensively—making their large propane tanks an invaluable asset. However, cold weather threw a real damper on the whole thing, impeding the flow of propane significantly. When Enduraplas’s plastics manufacturing process needed heating assistance, Powerblanket was able to deliver a custom propane tank heater that increased efficiency beyond expectations.

Our propane tank heaters efficiently restore warm weather psi and gas flow during even the most bitter winder conditions. With the Powerblanket custom heating solution in place, Enduraplas was able to run their manufacturing processes through the coldest of weather.

Gold Coast Yachts

Gold Coast Yachts builds custom, carbon-fiber yachts. The large sections of carbon-fiber frames need high-temperature exposure for long periods of time. Gold Coast had to design, build, and use large custom ovens for every cure.

In other words, they had to build a large shed around every frame in order to pipe heat into the enclosure and cure the resins at the proper temperature. This process, as you can imagine, took a whole lot of time, manpower, and money. With Powerblanket, curing is a breeze, whether it be resins, epoxy, or concrete. Our heated curing blankets cure faster and stronger than insulation or radiant heating alone. After teaming up with Powerblanket, Gold Coast Yachts was able to save thousands of dollars and hours of curing time on each project.

Cenovus

Cenovus is a committed member of the Canadian oil and gas industry. Bitter cold Canadian winters were wreaking havoc with their valves and transmitters. Frozen equipment was costing Cenovus a lot of money and creating a lot of wasted downtime.

When Cenovus turned to Powerblanket to design a custom valve and transmitter heating solution, Powerblanket easily and quickly engineered a solution. Powerblanket set out to create a custom pipe heating system that eliminated the risk of losing money, time, and energy to frozen instrumentation and equipment.

Powerblanket Custom Heating Solutions

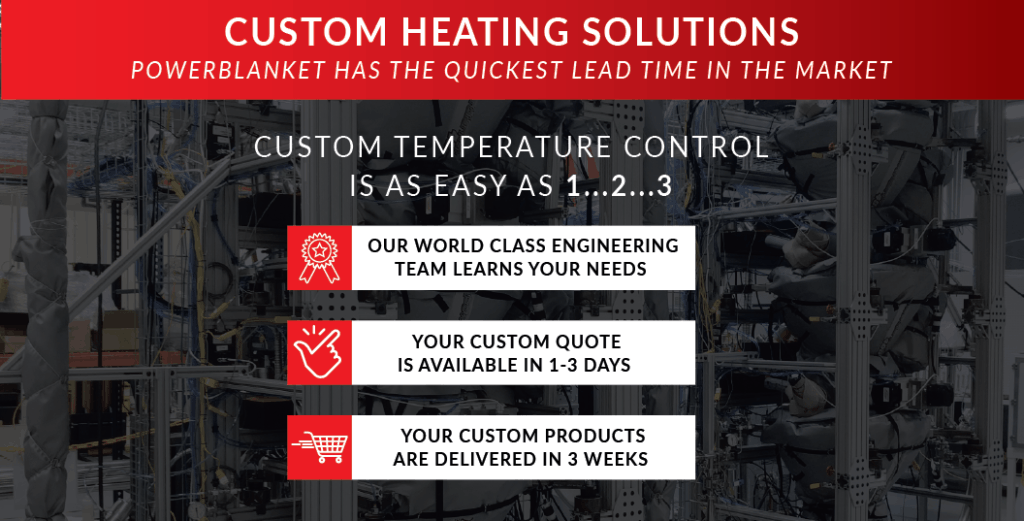

Many applications can be adequately covered by our ready-to-ship product lines. However, there are equally as many projects that need a custom solution. Powerblanket is proud to offer the quickest turnaround time in the market for custom orders.

Quickly Made To Order

Powerblanket’s custom heating solutions can be tailored to fit just about any application. If you can build it, produce it, or store it, Powerblanket can heat it. What’s more, completing a custom project with us can be summarized in 3 easy steps:

1. Contact us and tell us the details of your application.

Many of our custom projects start with a simple phone call to one of our reps. From here, you can send any and all information we’ll need to form the proper heating solution for you. Additionally, we do offer what we refer to as the white glove treatment. In other words, we can come onsite and get all the details on our own. Next, our world class engineers get to work right away.

2. We draw up your custom quote

Based on the information and feedback you provide, or that we collect from onsite inspection, your custom quote is available in 1-3 days.

3. We build your custom heating solution and and ship it to you within 1-3 weeks!

Contact us today to find the perfect custom heating solution for your needs at 844.557.4482 or [email protected]

When you need a custom temperature control solution, Powerblanket is the company to call. With over 30 years of experience, we can solve any heating dilemma you have.