When it comes to post curing, maintaining ideal temperature is a must. And if you’re post curing small to medium sized parts, then you may find yourself using expensive ovens, or else taking a whole lot of time and money to build your own. Thankfully, you don’t need to do either of these with the Powerblanket Hot Box on hand.

Post Curing: Bring the Heat

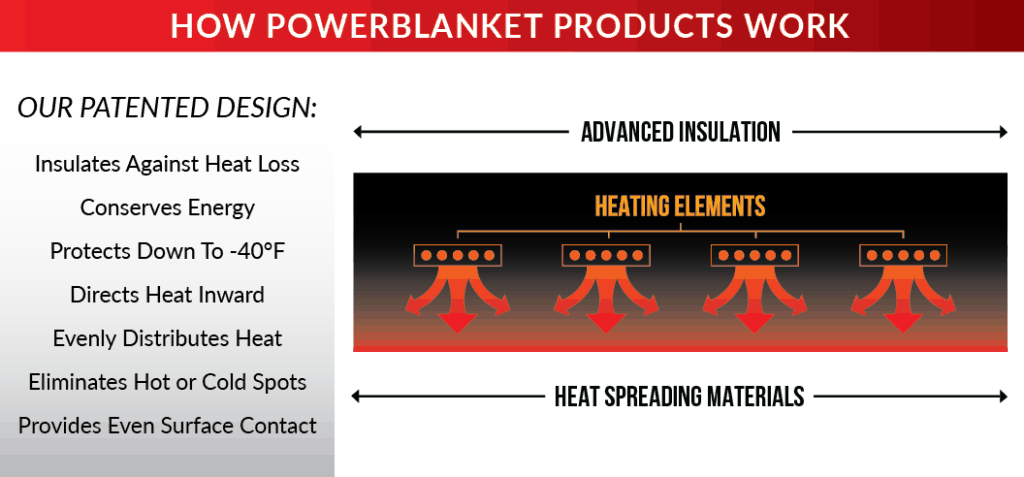

Post curing is a process during mold making that consists of increasing heat to a mold after the initial curing phase. Doing so allows the mold to cure faster, as well as enhances the physical properties of the mold. During post curing, heat must be evenly transferred to the mold at a constant rate as to not interrupt the natural curing process and cause irreversible damage. These damages can cost time in redoing the mold and in money for having to use extra materials.

The best way to heat molds during the post curing phase is to use an insulated hot box. Hot boxes provide regular, even heating to materials that require protection from low or fluctuating temperatures.

The Powerblanket Hot Box

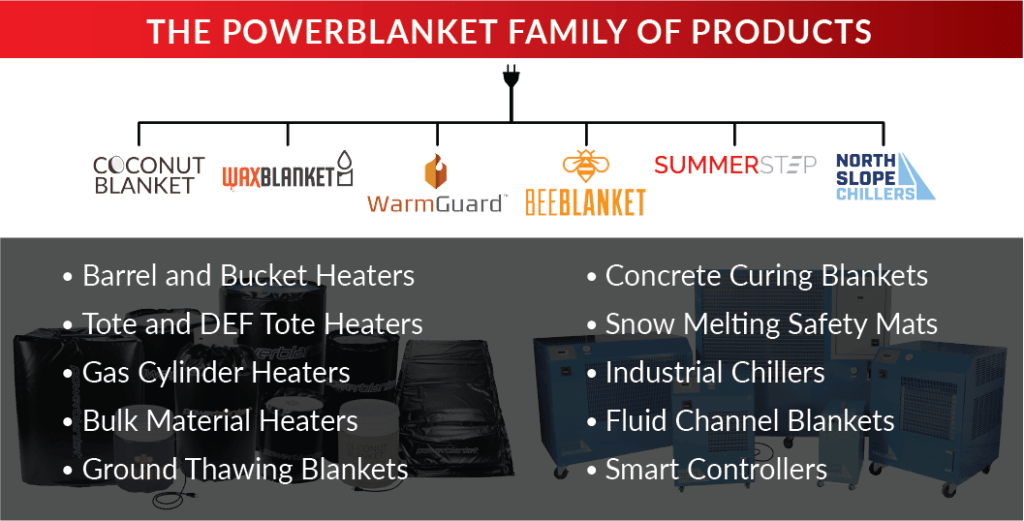

Powerblanket’s Hot Box (sometimes referred to as a Bulk Material Warmer) works great at maintaining the needed temperature for post curing small to medium sized parts. These insulated heating boxes provide an even spread of warmth to give the mold the exact increase of temperature desired.

The Hot Box’s durable construction allows for secure and lasting installation, while its ease of setup makes it transportable and storable. The Powerblanket Hot Box can be easily assembled, disassembled, and reassembled. It gives you the option of bringing your parts to the Hot Box or bringing the Hot Box to your parts. Our Hot Boxes hold product at a temperature of up to 120° F, and the optional adjustable thermostatic controllers allow temperatures to be controlled with precision.

So if you need to keep your epoxy cures at temperature for prolonged periods of time, a Powerblanket Hot Box just might be the thing for you.

Our Premium Hot Box (HB64PRO-1440) Offers:

Our Premium Hot Box (HB64PRO-1440) Offers:

- A larger footprint (48” x 48”)

- An internal steel frame (48” internal height)

- The highest wattage (1440 Watts)

- A controller for precise temperature regulation

Post Curing with Powerblanket Curing Blankets

Post Curing with Powerblanket Curing Blankets

Of course, after talking about the Hot Box, you may be thinking, “Yeah, but what if what I need to cure is bigger than 48” x 48?” Well, there are two simple answers to this question. Depending on your application needs, we could build a custom size Hot Box for you. But if one of our resin curing blankets would work better, we would certainly suggest this as an option.

A Blanket for Every Business

If you have curing needs that go well beyond what our Hot Boxes can handle, in regard to size and temperature, then our curing blankets are the ideal answer. Our high-temp flat blankets have high watt densities and produce higher temperatures for post curing epoxies and resins that require ranges beyond 100° F – 120° F, up to 400°F. What’s more, these blankets can be made to cover large areas simply and effectively.

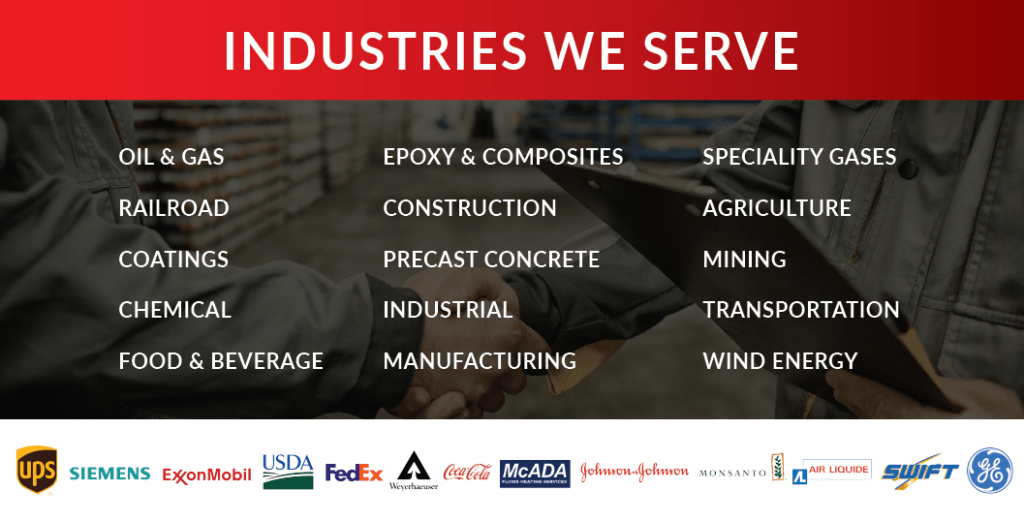

If you need it heated, Powerblanket has a solution for it. Whether it’s carbon fiber construction, wind blade repair, floor coatings, or some other resin post curing application, Powerblanket has all the options you need to consider paired with a team of world renowned engineers to ensure your project specifications are met. For more information, call 801.506.0198 or visit [email protected].

The Powerblanket Hot Box is the perfect solution for your bulk material heating needs.