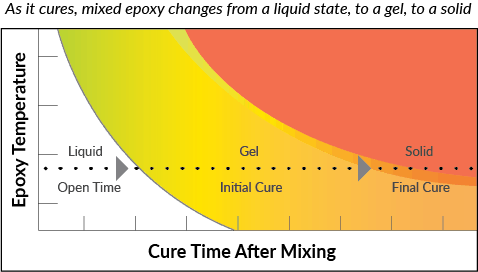

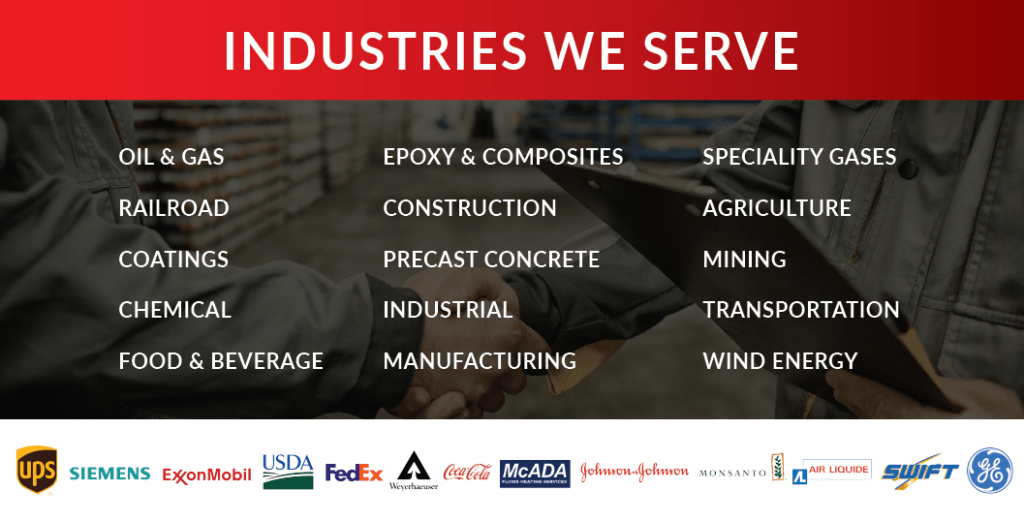

Epoxy curing has its challenges. Most resins for composite construction need post curing heat assistance. There are different approaches you can take for post curing temperature control. But of all the tactics and options available, there are really only two kinds: those that cost a lot of money and those that don’t.

Post Curing Epoxy Resins

Post Curing Epoxy Resins

When it comes to epoxy curing, most every epoxy resin, especially those used in composite and carbon fiber construction, has to cure and post cure at high temperatures. Normal ambient temperatures, even during hottest summer months, are never enough.

Gold Coast Yachts

Many companies have taken advantage of electric curing blankets to help with epoxy curing. Take Gold Coast Yachts for example. Gold Coast Yachts manufactures high-end, carbon-fiber catamaran watercraft. Their assembly process used to involve a very expensive and time-consuming procedure for post curing the large carbon frames.

The Easy Way or the Hard Way

Before Gold Coast starting using Powerblanket Curing Blankets, they had to post cure their carbon fiber structures in large ovens. But get this; they had to construct an autoclave oven themselves. When you have to post cure structures as large as Gold Coast does, you’re not going to find an industrial oven big enough. Instead, Gold Coast had to essentially construct rooms around the carbon-fiber body so they could then pump enough heat into the enclosed space for the post cure to set properly. They built a large shed around each and every frame. Workers used two-by-fours and sheet rock and created a sealed unit to pump heat into. Once they completed building the unit, someone had to man the oven for the duration of the cure to regulate the temperature. To prevent a compromised process and time delays, they could not allow the temperature to fall below 145° F or climb too high above it. If this sounds time consuming, it’s because it was. It is also very, very expensive.

Even while pumping the constructed oven with ample heat, Gold Coast was still having trouble penetrating through all the layers of carbon fiber. If the right amount of heat didn’t penetrate through all layers, the cure wouldn’t set completely. This long, costly, and inefficient process began to eat into the company’s valuable time.

Epoxy Curing Essentials

Curing is what makes using epoxy resin so difficult, but the results, if the curing process was completed correctly, are worth it. In Gold Coast’s situation, temperatures during that process must be kept above 145° F. This is to ensure that any moisture remaining in the epoxy resin is evaporated away, resulting in a hardened epoxy that is water tight and ready for use. The bigger the object that is getting cured, the bigger the industrial ovens you will need in order to provide even, consistent heat across the entire project at the same time.

When the temperature in an epoxy cure is not managed efficiently, the following less than desirable outcomes are likely:

- Discoloration/Yellowing

- Color Variation

- Blushing

- Uneven Gloss

- Poor Inter-Coat Adhesion

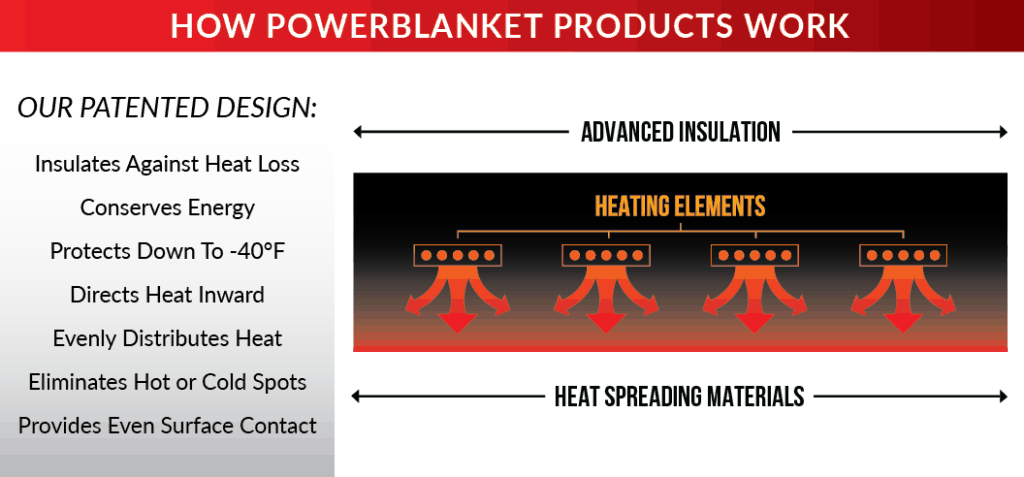

Most often, these results come from using heat sources that are not very effective. Heat trace, space heaters and open flame heat sources do not provide even, consistent temperature uniformity, and can have disastrous effects on your epoxy curing project. Without proper curing, projects are ruined, creating waste that the company has to pay to throw out and pay even more to restart the whole project. That’s why curing blankets are the preferred choice for epoxy curing.

Choose the Easy Way

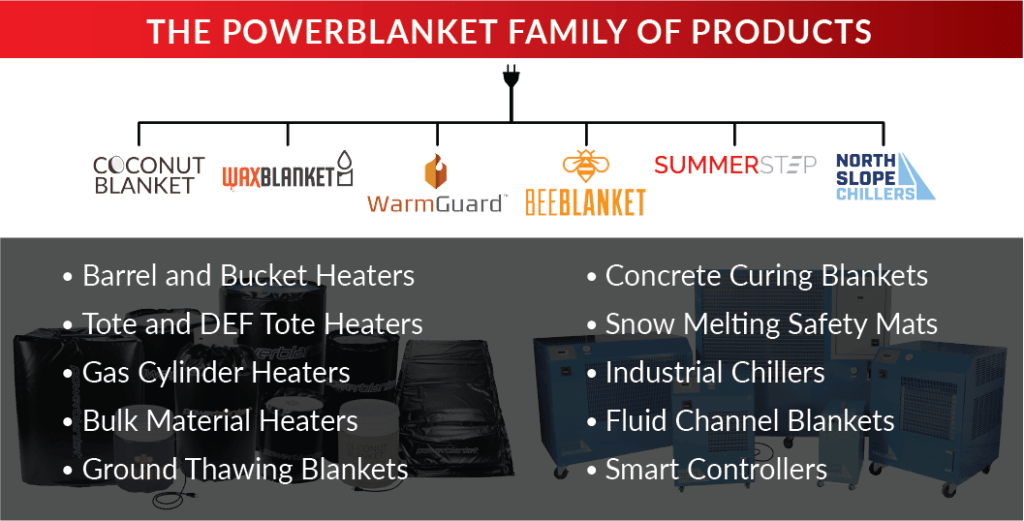

Once Gold Coast started using our curing blankets, however, they began saving thousands of dollars and hours (even days) worth of time. We were able to customize the right size curing blankets for them to use in insulating and heating their structures for post curing perfection. No longer needing to construct oven rooms to cure epoxy, Gold Coast Yachts was able to focus on other parts of their manufacturing process instead of worrying about how well their epoxies would turn out.

Curing Blankets are the Best Solution

Big yachts made of carbon fiber aren’t the only large-scale dilemmas for epoxy curing. We also have several clients in the wind turbine business who use our blankets to cure the seams in those gigantic blades that go on the wind mills we all see generating so much electricity. Imagine trying to find or build an oven for one of those.

Now, the question is: what can our curing blankets do for your curing needs? Whether you have big or small parts to cure and post cure, Powerblanket curing blankets can save you the time and money associated with curing ovens. Curing ovens are expensive, and they’re limited in size and transportability. Our curing blankets, on the other hand, have no such limitation and are much, much easier on the pocket book. We have many standard sizes and we can quickly design and build custom sizes at a very reasonable cost.

You can find more information about epoxy curing blankets here.

Frequently Asked Questions

Can I cure epoxy in the oven?

While it's possible to cure epoxy in an oven, it requires extreme caution due to the risk of uneven heat distribution, which can lead to warping or cracking; using curing blankets offers a safer and more consistent alternative.

What temperature should epoxy cure at?

Epoxy resin typically cures best at temperatures above 145°F, especially for large-scale projects, to ensure complete curing and avoid issues like discoloration or poor adhesion.

What temperature is a curing oven?

Curing ovens for epoxy often need to maintain temperatures above 145°F to ensure even and effective curing, but constructing such ovens can be costly and time-consuming compared to using curing blankets.

Can heat help epoxy cure faster?

Yes, applying heat can accelerate the epoxy curing process, and using curing blankets provides a controlled and efficient method to achieve faster curing times without the drawbacks of traditional ovens.

Cure your epoxy resins faster and easier than ever before with Powerblanket.