Welding Preheating

Prepping pipes and other surfaces for welding can be a real challenge since metal surfaces often need to be hot before you begin. If the metal isn’t hot enough before you start welding, it will affect the cooling rate. If a weld cools too quickly, the metal could go into shock and cause fabrication hydrogen cracking. There are many metal preheating methods. Some of these include: furnace heating, torching, electrical strip heaters, induction heating, and radiation heating, and welding preheat blankets.

Why Preheat Metal?

When you preheat and post-heat the metal, it allows for better hydrogen diffusion; up to 1000 times more diffusion at 250 °F (121 °C) than at room temperature (68 °F, 20 °C). Cracking risks reduce as more hydrogen diffuses after the weld is complete.

Types of Heat Transfer

There are 3 main types of heat transfer: convection, radiation, and conduction. All 3 methods are useful in different applications. Let’s take a closer look.

Convection

Convection transfers heat around a space by the movement of molecules. For example, the rolling circular motion within a pot of boiling water is convection heating.

Radiation

Radiation is the transfer of heat through electromagnetic radiation. Radiant heating is what you can feel in the air when you sit around a campfire.

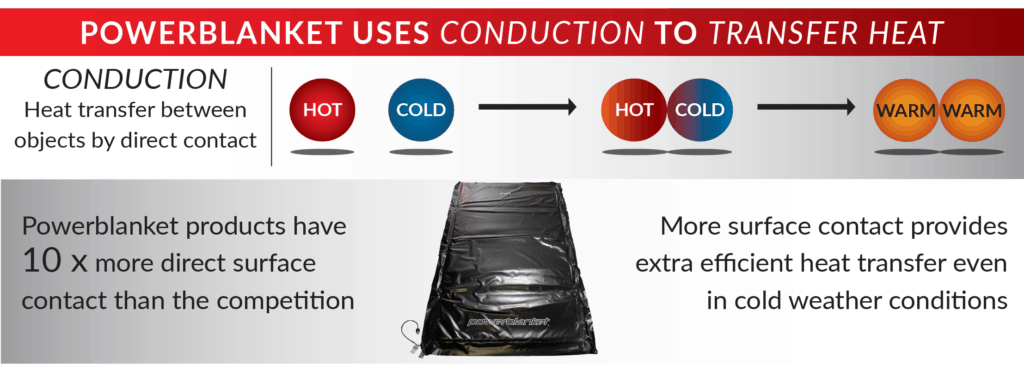

Conduction

Conduction transfers heat through direct surface contact. This is the most efficient heat transfer method to use when preheating a wide variety of metal surfaces for welding. Radiant heat will waste time and energy heating the air around the metal instead of the metal itself. Direct contact will ensure even, consistent heat over the surface of your welding materials.

Let’s compare 2 different welding preheating methods. Induction heating using radiation and heating blankets using conduction.

Induction Heating vs. Heating Blankets

Induction heating involves coiling a conductive metal object around the surface or container that needs to be heated. Electromagnetic currents then circulate and heat the object they surround. Once these metal coils are in place, they are not easy to remove and re-install. Induction heating is well suited for objects needing continual applied heat in a fixed, controlled location. Induction is commonly used in factories, where long strips of piping are continuously fed through the center of inductive heating coils.

However, for field work welding and on site repairs, induction is not a practical solution, especially in colder weather. Welding in a dynamic environment requires more portable and flexible preheating options. High temperature heating blankets are flexible enough to conform to and heat any metal in need of welding. They also use conductive heating that evenly distributes across the entire metal surface.

Welding preheat blankets are easily installed, removed, stored, and placed in another welding location.

Powerblanket Welding Preheating Solutions

High Temperature Heating Blankets

Powerblanket specializes in innovative heating solutions that fit a wide variety of surface shapes, and can be used in a myriad of locations. Our portable heating blankets come in every shape and size to accommodate any welding job.

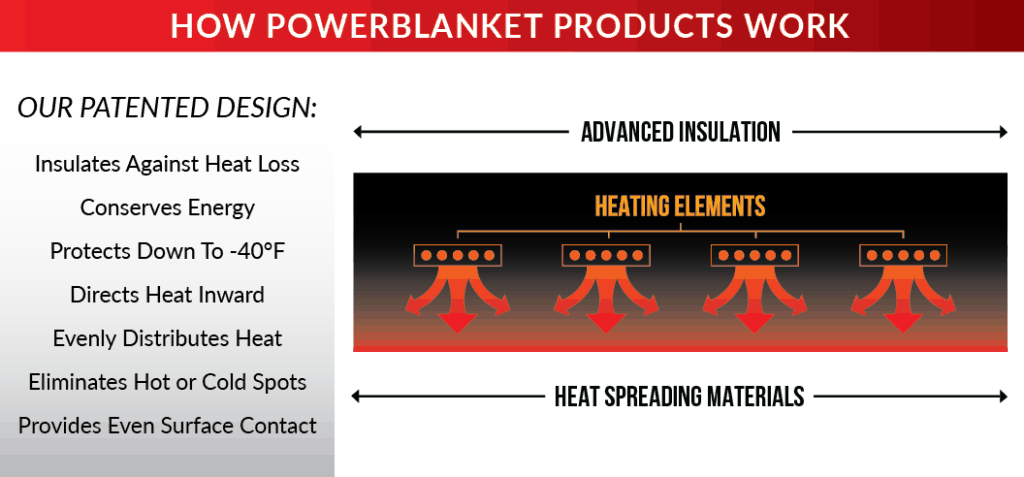

Thick insulation and efficient heating spreading technology drive heat downward into your welding surface, eliminating hot and cold spots.

At Powerblanket, we also provide heating blankets that are certified to be used within hazardous locations. Safely preheat metals in C1D2 locations, so you can weld wherever needed.

Gas Cylinder Heaters

Our gas cylinder heaters and propane tank heaters are the perfect fit for tank welding jobs. With a large selection of sizes available, Powerblanket can fit and preheat any sized tank, even when welding in the coldest of conditions.

Contact us to find the perfect preheating solution for your welding needs at 866.945.4203 or [email protected]

Powerblanket's superior heating solutions reduce costs by optimizing container temperatures and increasing cylinder efficiency.