Cold weather has the ability to shut down your entire piping system if not properly mitigated. Pressure valves, flow meters and other temperature-sensitive components are especially prone to freezing. What steps should you take to prevent valves from being vulnerable to the cold?

Thawing Versus Freeze Prevention

It is easier to find a method of freeze protection rather than to thaw a valve that is already frozen. It takes a lot more energy to thaw a solid than it does to warm it enough to avoid freezing. Stop valves from freezing by not letting them get cold enough in the first place.

Valve Freeze Defense

The best way to avoid valves from freezing is to apply a direct source of consistent heat. When pipes and valves freeze up, it can cause some down time along with additional costs for damaged valves. Begin taking precautions by seeking out parts of your system vulnerable to freezing.

Identify Sensitive Equipment

Valves are particularly prone to freezing up when the temperature drops too low. So are pressure monitoring equipment and other flow controls on your pipe system. These areas should be regularly checked to ensure there is no buildup of water moisture or frost, as these are key indicators of the early stages of pipe freezing. This is especially important if you currently are not using any kind of heat source to prevent your equipment from succumbing to the cold.

Avoid Operating in Cold Temperatures? Yeah, Right

Regardless of what is flowing through the pipelines, avoiding damage means to avoid freezes, especially during the times that the pipelines are not flowing. However, this is not always feasible. Operating in cold weather is always inevitable. It’s best to be prepared to deal with the potential for freezing valves instead of hoping it will never happen to your equipment.

Options for Keeping Valves Ice Free

There are many ways to prevent valves and other freeze-prone equipment from heading too far into the cold:

- Draining and bleeding pipelines and valves

- Works great in your home or commercial sprinkler system, but this may not be feasible in all operations. Some pipelines run continuously, and cannot afford to be shut down to empty them of fluids.

- Electrical Heat Trace

- Though heat tape is efficient at melting ice and keeping cold away from temperature sensitive equipment, using this type of warmer can limit access to valves.

- Building temporary housing/heating units

- Constructing a shelter over valves and other parts of your pipeline can take time, material and labor away from other parts of your operation. Then there is always the potential that such housing can collapse in high winds. Plus, you have to rebuild it every time you need it.

- Temporary heating solutions such as propane or space heaters

- The key word here is temporary. In most environments, it won’t be cold year round. However, propane and space heaters are less safe to use due to the potential to ignite flammable vapors that might be emitted from pipe leaks. They also don’t provide an even amount of heat, much of which dissipates due to no surface-to-surface contact between the heater and the valve.

- Heating blankets or heating wraps

- This is the preferred option, which is explained in more depth below.

Heat Your Pipes With Heating Blankets

Only one method of freeze mitigation can truly protect control valves. To prevent valves from freezing, heating them is recommend. A safe electrical heating source is the best way to go. You need to be able to control the temperature safely and evenly to avoid damaging valves or the contents inside pipes.

Finding a solution with an even distribution of heat is also important to avoid hot and cold spots. The best product on the market today for heating or thawing valves would have the following features:

- Easily installed or removed

- Easy access for monitoring and maintenance

- Even and efficient heat

- Meets current safety standards

- Available in standard and custom sizes

- Durable for year-round cold weather use

- Flexible for storage during the warmer seasons

Find a solution and get it installed before the cold season begins. When searching for an answer to potential valve freezing problems, look for a cost effective solution that can be easily maintained and installed without the costs of additional labor and monitoring.

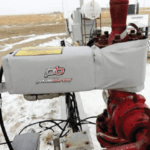

Powerblanket Valve Heaters

Powerblanket heating blankets are the number one valve heaters available anywhere in the world. Manufactured in the frozen heights of the North American Mountain West, these insulated heated blankets perform in temperatures well below freezing. Custom Powerblanket pipe heaters can go even lower, keeping pipes warm even in places as cold and remote as the Arctic Circle. Powerblanket enhances operational functionality of tanks or flow systems by wrapping around and heating the exposed valves preventing critical cold weather related problems, thus reducing unnecessary costs related to shut-downs and repairs.

For more information about Powerblanket valve heaters, contact our temperature control specialists by calling 866.945.4203. or by email at [email protected].

Powerblanket's equipment boxes keep your valves and manifolds from freezing in even the harshest outdoor environments.